Results 81 to 90 of 91

Thread: Can't get 2 razors to shave

-

06-15-2020, 11:54 PM #81Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

It is a matter of understanding what you are seeing with magnification, the more magnification, the more you see. Not seeing it, with less magnification, does not make it go away. Guys that can hone with loups, already know how to hone.

Understanding what you see will teach you the causes, what you are or are not doing. More than likely you are doing too much. So, simplify. 2,4, &8k should get you to a bevel and edge like the above post.

Never learn on a prized possession. Get an inexpensive razor with a straight edge, no smile, no round point, shoulder less, (no stabilizer) and no excessive hone wear, learn to hone that. A Red Imp, Wedge, Spike or a Genco. All good razors that will hold a good edge and provide a lifetime of shaves.

Look at the bevels and edge at each stone in the progression and match the bevels and edge to the micrographs in the Second Try at Honing.

When you look at the bevels in the progression look at the edge, it should be as chip free and straight as possible. At 8k it should be very straight with only 8k stria on the bevel.

What you want to learn is what the bevels and edge should look like at each stage in the progression, with out any other issues that can cause problems.

The one thing you will have to pay attention to with a shoulder less razor, is pressure. Too much pressure will flex the blade and lift the edge off the stone.

It will teach you a lot about pressure and your stroke. Too much pressure with any razor can lift the edge off the stone.

Here is a Union, Spike, that would be perfect to learn on. You can pick them up for $20-30. There are probably 30-40 for sale on eBay from $11 to over $100, most $20-35.

Spikes were made by a few folks all are good and most importantly, super easy to hone. They also shave a dream.

-

06-26-2020, 12:52 AM #82Member

- Join Date

- Mar 2011

- Location

- Gyptuckey, CO

- Posts

- 57

Thanked: 1

I picked up a couple cheap un-honed practice razors. I've been looking at ebay. There aren't any Unions in the condition of the pic posted for $30 +/-. I did miss a brand new one in original packaging that went for dirt cheap 'cuz I wasn't around at the time the auction ended... Most of the razors currently listed for under $30 are quite rusted, excessively worn, etc. I wanted a clean razor to practice honing on, not a project, hence the cheap Chinese-made option. I'm watching some other on ebay as well.

I spent quite a bit of time setting the bevel on a 500 synthetic. Spine taped. Changed the tape often. The hollow face is much thicker right at the heel than the toe. The entire face feels consistent, then right at the heel it gets much thicker. There's a slight smile to length of the blade. The bevel is becoming much wider right at the heel. There's a small frown starting right in front of the heel. I focused on heel forward strokes, just at the heel, for quite a while. I was seeing the slurry creep up the bevel right in front of the heel, but not at the heel, and that where the frown is. Rocking the edge on a flat table there's a noticeable flat spot, or rather a spot that doesn't rock smoothly due to the frowned area in front of the heel.

I'm thinking of breadknifing and/or high-angle grinding right at the heel to get the smile back, and prevent the frown from growing. And then focusing on getting the bevels to meet just at the thicker heel area. Or maybe just increasing the diameter of the curve at the heel to take the thick part of the face out of the equation all together.

The bevels are meeting at the rest of the blade length, and are fairly even. So far, at 500 grit, the edge won't cut hair. It'll cut tomato skin (personally I think this is a silly test; All of my razor honing can cut tomato skin easily, but doesn't translate at all to how it shaves. I did know of a chef on another forum who used to shave w/ a 150mm petty knife, and posted videos of himself doing so. Not for me, thx...). As always I welcome any feedback. Thx.

-

06-26-2020, 01:08 AM #83

I think I would start with a heel correction. That will (or should) take some of the uneven bevel problem out of the equation. Try taking a coin and set it on the blade to see which is the same width or close then move it to the heel even with the edge, spine and shoulder. Take a sharpie and mark the outline on the heel and use a DMT to bring the heel to that curve.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-26-2020, 02:16 AM #84Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

What does the other side look like?

I recommended a Union Spike because they are very well ground, shoulder less and of excellent steel, all of which makes them without issues and easy to hone.

Chinese razors are what I consider a Kit razor, they are full of issues and generally poorly ground. Yours is no exception

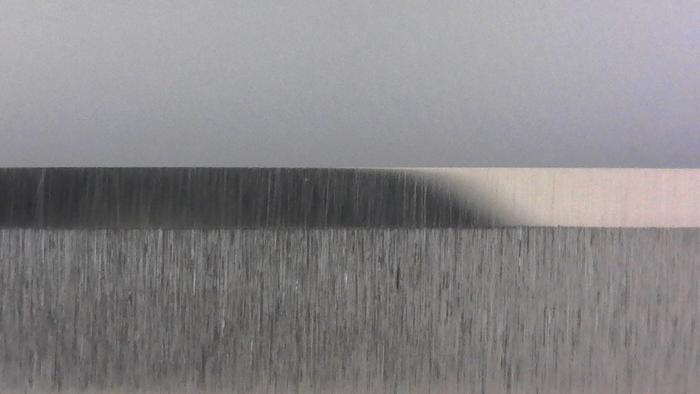

Compare the photos of the heel to the toe photo and you will see they are ground very differently, and the spine also unevenly ground matches the uneven bevel and edge.

If you make some repairs to this razor, you can make it take an edge, but before you can hone it, it must be repaired and even with correction, it will be a challenge to hone as a learning tool.

Buy a shoulder less American made razor to learn to hone, then you can learn to repair a defective razor.

This is like learning to drive, but first you must rebuild the engine.

-

06-26-2020, 07:03 AM #85

What brand/model is that? Euclid is right. In general, Chinese razors are not very good for learning to hone on. You really need to get a handle on honing in general before tackling them. Their only real recommendation as a honing learner is that they are cheap, expendable, easily replaced. The problem with them is that a lot of correction is usually called for, just to get plenty of bevel flat on the hone. They are perfectly okay razors once they are corrected and initially honed. It is getting them set for the first time that will frustrate you as a beginner.

If you must learn to hone with a Chinese razor, I suggest the Gold Dollar P81 AKA "1996", or 208, 600, or 800. Still a handful for a beginner but not as bad as most.

-

06-26-2020, 03:22 PM #86

Yes the Chinese razors can be a real pain in the butt to hone, but arguably you will come out with more skill due to knowing how to correct different issues.

Fix the heel , as Paul mentioned, then rolling x until you get the frown into a slight smile.

You seem to be on the right path I’m sure you’ll figure it out. These guys are giving you all the information you need. A good bunch really.

-

06-26-2020, 04:25 PM #87Member

- Join Date

- Mar 2011

- Location

- Gyptuckey, CO

- Posts

- 57

Thanked: 1

I bought 2 of these blunt practice razors from Classic Shaving for $13 each. The razor pictured on their site is different from what was sent, and they acknowledge that in the listing. They're unbranded. Plastic scales. The same blade is currently being sold in other stores under different brand names with different scales; Zertone on Amazon, Gold Dollar P81, AKA "1996" on ebay. It's fine for me to practice identifying, correcting, and dealing with issues.

I plan to increase the diameter of the curve at the heel to remove the thicker part of the face grind from the edge. Then work on x-strokes to get the smile even again.

-

06-26-2020, 05:03 PM #88

Gold Dollar sells a lot of unbranded or custom branded blades. They are all made in their Ningbo factory. In fact I just ordered 100 of the P81 blades, unmarked, no scales, direct from the factory. Anyway, now you know where it came from.

I still think a vintage straight edged American razor would be a better learning platform for you. Trimming the heel will make it a little easier to hone but there still may be issues with the edge not being aligned with the spine, etc. If you stick with it and do not give up, you will probably be eventually successful, but I wouldn't wish that on anyone, to be forced to learn to hone on a GD no matter what model. I have probably honed about 300 of that brand and even for me it can be a bit of work and challenge my skills to get it started correctly.

One last word. Most of the GD models have a very thick spine and a bevel angle of around 18 degrees. You REALLY should not use tape on these razors even if you would normally hone other razors with tape. You do now WANT to preserve the spine thickness. You want it to get thinner if at all possible, for optimum performance.

-

06-28-2020, 02:52 PM #89Member

- Join Date

- Mar 2011

- Location

- Gyptuckey, CO

- Posts

- 57

Thanked: 1

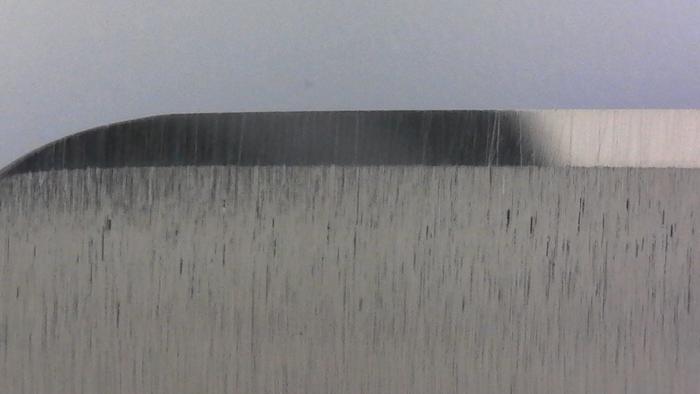

I ground a larger radius at the heel to try to get the edge out of the thicker ground area. I could have made it quite a bigger, as there is still a thickened area at the beginning of the edge. I marked a curve using a circle template, but ultimately just free-handed it. I used a dremel w/ a sanding drum at the lowest speed. Then a a wire brush to remove the burr at the ground edge. I used the wire brush a t highest speed to see what would happen, and it slightly discolored the face in a small area. I continually checked the metal for heat, and there was never any noticeable heat build up.

There's a wobble on both sides when laid on a flat surface. So, I taped the edge and ground the spine w/ an Atoma 400. I was able to reduce the wobble, but eliminate it. on one side the heel is lifted, on the other side the toe is lifted. I felt like I could keep grinding and grinding, so I just stopped.

I proceeded to 500 stone, focusing on x-strokes and the heel-forward strokes. No tape on the spine. The area right in front of the thickened part of the heel still keep grinding away quicker. I had to lightly breadknife the edge at the heel a couple of times on the Atoma and re-set the bevel at that area. I got the edge to where it would bite into my thumb nail and grab arm hair along the entire edge.

Then I went to 1k, 6, and 10k stones. No tape on the spine. I had to really pay attention to using rolling x-strokes, and occasionally direct pressure at the thick heel area. The spot in front of the heel is still flattening. It will always be a problem and require special care.

The edge got keener at each progression. At 10k, arm was popping with no resistance. So, I did a few strops on 1m diamond paste on leather, a few strops on 0.5m diamond spray on felt, chro-ox on leather, and naked leather. Then shaved with it.

It was one of the best shaves I've ever had. Sharp, smooth, no irritation at all. It shaved evenly along the length od the dge, except at the very, very ends of the heel and toe where where the edge turns into the radius and the bevels don't meet. Usual problem areas that I have to touch up, weren't a problem at all. The day after a shave is when I start to notice effects of razor burn and irritation, and there are none at all. This razor shaved far better than A.W. Wadsworth I started this honing inquiry with.

Overall I'm very pleased with how this razor turned out. I had no expectations, I was just planning on using it for muscle memory and experimentation. It's not perfect, and I'm not quite sure yet what to do to correct some of the geometry issues. It's been a useful tool to learn on, and frustrating as well. I spent about 3 hrs on it. I couldn't have gotten to this point without all of the great feedback and advice everyone here has given me. I'm grateful for it - THANK YOU! I realize this is a learning process. I have in no way mastered it, and I still have a lot to learn and experience.

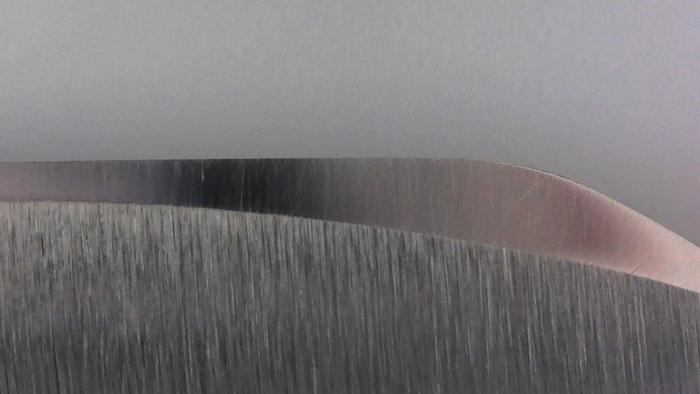

When I re-ground the curve at the heel, I had the curve very smooth and uniform as it transitioned from the edge. But as I honed the edge, a very slight corner started to develop, as if the edge was becoming raised above the radius of the curve. It's clearly visible in pics #1 and #2. That little corner wasn't there when I finished the dremel work. That's puzzling to me... A similar little corner can be seen at the toe, when the edge transitions to the curve. I did not do anything to the toe of the blade.

These pics are all post-stropping. I didn't take pics along the way.

-

06-28-2020, 03:02 PM #90Member

- Join Date

- Mar 2011

- Location

- Gyptuckey, CO

- Posts

- 57

Thanked: 1

Looking at the pics and thinking a little further, that little corner at the transition of the bevel into the heel curve is forming because the edge in front of it is being worn away much more quickly, and the radius of the slight smile is decreasing. That will eventually turn into a spike without proper attention. I get it now. I'm just not sure how, if possible, to correct the geometry to prevent this from continuing. Unless the geometry can be fixed, it seem like hyper-focused rolling x-strokes will always be necessary. And possibly breadknifing and re-setting the bevel in that area as needed to maintain the smile?

148Likes

148Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote