Results 161 to 170 of 185

Thread: Learning Jnats with Microscope

-

06-29-2021, 02:03 PM #161Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Steel damage goes much deeper than the bottom of the impact/chip. Add to that the steel at the edge is very thin. So, even if the damage is from striking the scale, (which must be fixed) it is impact damage and all the metal along the edge must be removed to the level of the bottom of the chip and more, to get to solid steel.

With tools, plane blades, chisels, and axes, you grind the steel at 90 degrees to remove all the steel quickly and efficiently, then bring the bevels back to meeting. With razors some hone it out, it makes no difference, the exact same amount of material must be removed.

If the blade is hitting the scales, it may be as simple as tightening the pivot pin, a few light taps on the pin will tighten it. If un-centered you tap the back of the pin in the direction you want the tip to move, tap the other pin in the opposite direction.

If you do not repair the blade centering, the first time he closes the razor he will ruin the edge.

If repairs need to be made, you first, make the repairs, then hone. If a heel needs correction, it can keep the heel half of the razor off the stone or prevent it from making full contact. Look at the spine over the stabilizer if you see any wear marks the heel corner is too close to the stabilizer.

Heel correction literally takes a minute.

If the bevel is uneven from heel to toe on both sides, the heel needs correction. If the bevel is uneven and the wear is the opposite on the other side the razor is warped. You hone each side differently, so you need to know which side in convex and which is concave.Last edited by Euclid440; 06-29-2021 at 04:01 PM.

-

07-01-2021, 04:19 PM #162Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

There is learning to hone, then there is learning to hone other people’s razors.

You have made great progress in improving an Jnat edge using a nagura progression, but honing a single or hand full of razors varying technique or stones is one thing,

Honing different razors with a variety of issues, is completely different, especially razors that are not yours and you know nothing of their history.

Inspection and diagnose of issues prior to honing come into play. It is where folks get into problems, compounding these issues attempting to hone a blade that needs repair. Something as simple as diagnosing spine thickness loss, heel correction or edge correction can/will make or break a honing. Adding tape or using an alternate honing stroke can make all the difference.

First do a full inspection of the razor, check the spine for excessive or uneven wear. If uneven figure out why. Check the razor for flatness, if warped excessively each side may need to be honed differently. If minor, you may get away with just a rolling X stroke. A rolling X can heel a lot of sins and at the least should be the final stroke on the finish stone to blend and fully hone the edge.

But the rolling X must be done correctly, ink will quickly tell you if you are making full contact.

Check the heel, most razors with stabilizers can use some heel correction. Recently on another thread, I looked at the first 10 razors for sale on eBay, 9 or the 10 needed heel correction and some had spine and edge damage as a result.

Heel correction should be a part of regular blade maintenance, before honing.

Something as simple as loose pivot pin can affect honing and may cause the blade to hit the scales and close uncentered, running all your hard work.

It has often been said, before restoration put the blade on a 1k and see if it will hold an edge. It will also show you if it will hone an even edge. if not before restoration these issues must be corrected, polishing the blade will not make issues go away.

So, if you are honing a razor for the first time, take the time to look at it critically. If you see issues, figure out why and make corrections before attempting to hone. If you see issues when honing, STOP. Doing more of the same thing is never the answer.

Identifying and understanding defects and damage is a whole other and separate part of honing apart from setting a bevel and polishing an edge. Repair is repair, separate from honing. Unfortunately, this holds true, now for new razors. Most can easily be “repaired”.

-

07-02-2021, 12:48 AM #163

I have to admit that several years ago when I started with straights that I thought about a microscope but in the beginning I just used a loupe and that as short lived as I found the easiest way for me was to shave with it and go from there.

Iím sure my edges are not on par with those that use these modern techniques but my shaves are very acceptable for my taste and the edges I have done for others seem ok as they seem to like them."A Honer's adage "Hone-Shave-Repeat"

~William~

-

07-02-2021, 02:32 PM #164

Jnatcat

You're perfectly right! People honed razors for decades with no microscope and it's always worked. As I said in my first post of this thread: "Microscope doesn't hone".

It's just a tool... a tool like any other. But, it can be useful, dependig on the approach and on particular needs.

I decided to use it because I preferred a more systematic approach in honing's learning. I can compare what i do & feel to what I see. So, I try to better understand mistakes and/or thinghs I do the right way. Moreover... how else would it have been possible, without sharing images, to receive "targeted" and invaluable advice from a mentor like Euclid440 ... being thousands of miles away?

Obviously, not everything can be solved this way ... There are too many elements that contribute to success or failure, when honing a razor. That's why I've still a lot to learn...I know that I don't know (Socrates)

-

07-02-2021, 02:58 PM #165Senior Member

- Join Date

- Sep 2018

- Location

- Palm Harbor Fl

- Posts

- 379

Thanked: 49

As time goes on you will find ways to do what you want to do. Simple approach to me is the best way. I used to do 8 nagura progressions for an hour or more. WHat did it get me? IMO nothing, well i burned lot of dust and the fingernails were ingrained with slurry. I can do that with a synth progression leading to a jnat finisher. Or a midrange stone then finisher. I have 2 natural bevel setters that i havent touched in years. Why? Because its a tremendous waste of time imo. A bevel is a bevel is a bevel. So if your honing for results then you try to achieve it the fastest way possible imo anyway. If the fastest route to a friends house is a certain way I will take that route. Unless I dont mind burning gas and time for nothing. A nagura progression doesnt give you a better edge. As far as problem razors go? A lot of them should be put into a junk pile as theyre toast. Obviously something sentimental is something else. If your honing for others and someone sends you a $15 razor and it needs $50 to trim the heel, remove the chips and pitting etc, then its advisable to say to the customer that it will cost 4x the cost of the razor to get it shaving and shipped back. There is no shortage of vintages out there. Ive snapped more than a few of them in the vise. And thats to save the poor soul whose hands it may wind up in and the guy he sends it out to from the grief involved with restoring a razor that belongs in the junk pile. Its a hobby and it may be time consuming for sure. Take the hobby any way you like. Just my view on things, Ive been there and done that.

-

07-10-2021, 04:58 PM #166

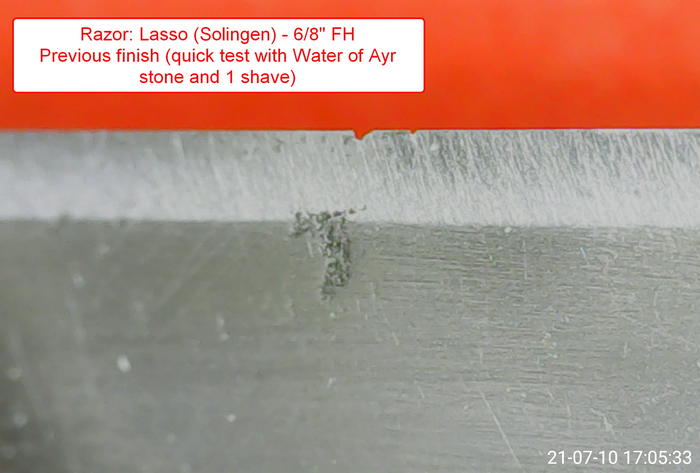

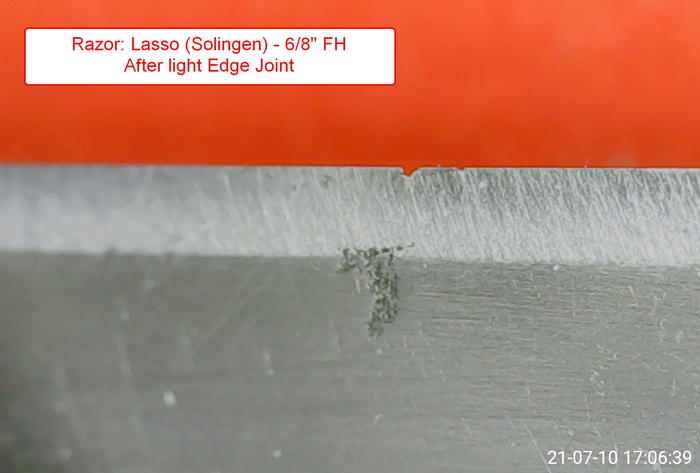

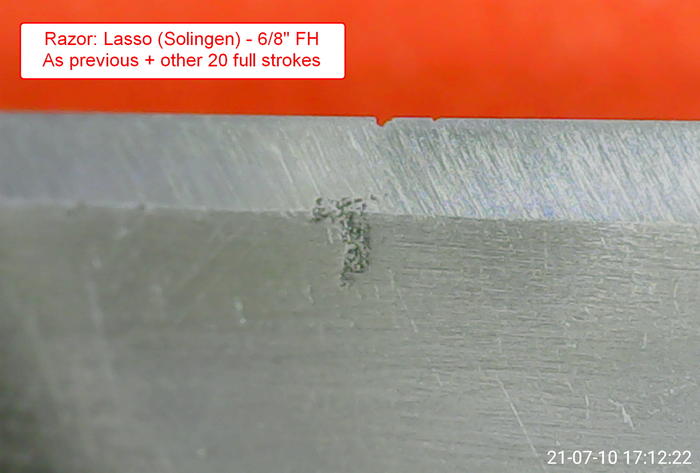

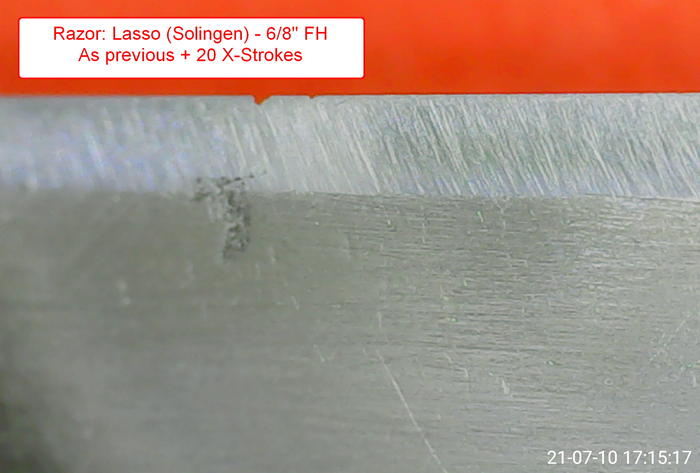

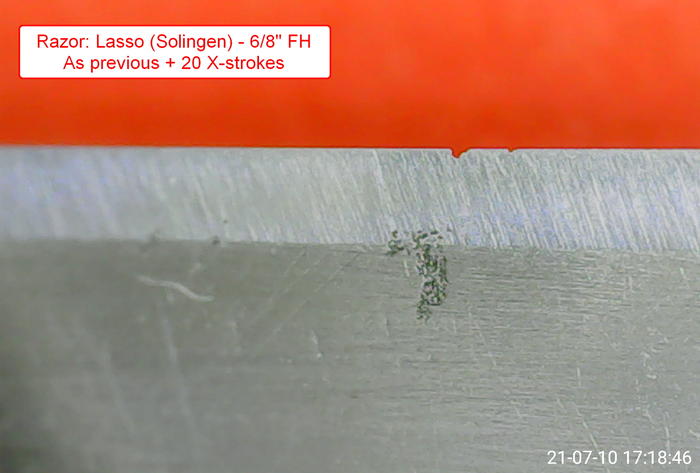

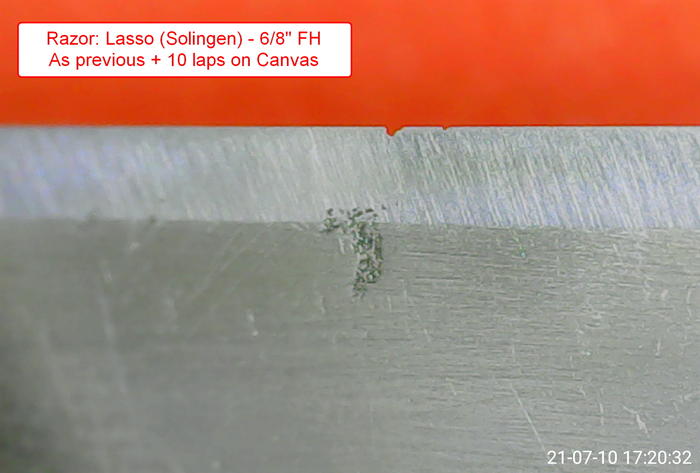

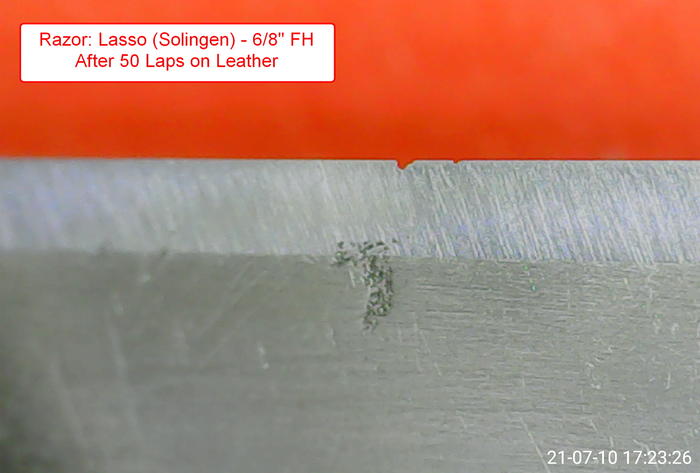

Naniwa Gouken Fuji 8K - First Test.

Naniwa Gouken Fuji 8K - First Test.

I recently had a chance to get a (like new) Naniwa Gouken Fuji 8K. For what I know it's one of the two made by Naniwa specifically for straight razors.

Despite being very busy at moment, I found some spare time (after more than a week it was @ home) to make a quick first test, just to see how it works...

Used the "usual" Lasso Razor (the one for Nagura tests on Ozuku) that had reecently a quick finish on the Water of Ayr Stone.

Made a little bit of slurry with an 1,5K diamond plate and then, 4 series as follows:

- 20 Full Strokes

- 20 Full Strokes

- 20 X-Strokes

- 20 X-Strokes

Completed the test with 10 Laps on Canvas & 50 Laps on Leather.

I'm not experienced enough to judge the microscopic results, but seems not bad to my eye.

Observation through a 40X Loupe showed a nicely polished bevel.

Blade passed easily the treetop test.

Shave test is scheduled for next Monday, as I wanna understand how it behaves on skin.

Next test will be an Ozuku Suita's slurry finish (to compare to the usual Nagura progressions)

Then I'll Test this 8K after a synt 3K and see how it handles the bevel setter's stria.

Last image is made after the four series described above.

I know that I don't know (Socrates)

I know that I don't know (Socrates)

-

07-10-2021, 07:52 PM #167Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I don’t have a Gouken,Fuji 8k, I do have the Junpaku Snow White and other 8k stones.

The Junpaku is a very hard, aggressive 8k that produces a fine bright polish and super straight edge.

Folks that should know,rate the Gouken Fugi as producing a more polished bevel and straighter edge than the Junpaku Sknow White.

For me, my Sknow White bevels are near mirror. I do not shave off these edges and use this stone as a jumping off point to Jnats, from a full bevel set.

I think you can improve the bevel quite a bit with that stone.

First make sure the stone is lapped flat, grid mark it with pencil and remove the grid fully 3-4 times. Make sure you are lapping the pencil off flat and not just washing it off with slurry.

Mark a new grid and it should come off completely in 5 laps or so.

Then be sure to bevel or round the edges to ensure you do not have any sharp corners.

While you can use a thin slurry with an 8k to make it more aggressive to remove deep stria, they will not polish well with slurry.

Wash the stone and razor then do finish laps on a clean wet stone, you should be able to easily get near mirror finish with that stone. I often use a Tsushima to smooth the surface of the Snow White after a quick lap with a worn 600 diamond plate. Then rinse off all the slurry.

It should be a great stone for jumping to a Jnat and easily refine 3k stria.

Lap and try it without slurry and lots of water, (squirt bottle).

BTW, this holds true for most synthetics, they will cut faster with slurry, but will leave a more random scratched bevel. Washing the stone and doing finish laps will produce a more polished bevel and straighter edge.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Skorpio58 (07-11-2021)

-

07-11-2021, 06:54 PM #168

Euclid,

I'll follow your hints for sure.

This was only a first quick test.

I got the stone from a vendor who already lapped it and made veeeeery little slurry just to avoid clogging. Added more water after each series too.

I'm really curious to know how he will behave tomorrow while shaving. I know that I don't know (Socrates)

I know that I don't know (Socrates)

-

07-12-2021, 10:28 AM #169

Update.

Update.

I shaved this morning with the Razor (pre) finished with the Naniwa Gouken Fuji 8K. (see a couple of posts above).

Got a very nice & smooth shave. Sincerely, couldn't say it was made with a synth stone. At least, it wasn't harsh how some people reports. Maybe it wasn't the closest ever, but easy & smooth for sure.

I'll have to test this stone deeper (as Eucid440 suggested), but it seems to have a big potential. I know that I don't know (Socrates)

I know that I don't know (Socrates)

-

07-12-2021, 01:48 PM #170Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

One can definitely shave off of an 8k, especially from some of the newer 8k’s that perform much like 12k’s if the bevel is properly set up.

It is also aggressive as witnessed by the swarf in the slurry, this also could be scratching the bevel, though the edge looks nice and straight.

This is said to be one of those stones capable of a higher finish. Any 8k, stropped on Chromium Oxide will provide a good smooth shaving edge. Not a Jnat edge, but a solid shaving edge. Chrome Oxide will bump the edge up to 20-30K.

For many years here on this fora the Norton 8k was the gold standard.

211Likes

211Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote