Results 121 to 130 of 167

Thread: How sharp do you like it?

-

04-19-2013, 06:16 PM #121

-

04-19-2013, 06:51 PM #122

Whatever stone you just used not what you started the progression with. So if you start with the 8k, then you say go to the 12k and stop; or you could say go 8k then 16k b/c the grit range is no more than double the previous grit hone. As was mentioned earlier, this would be easier than say going from 4k straight to 16k to finish.

Mastering implies there is nothing more for you to learn of something... I prefer proficient enough to not totally screw it up.

-

04-19-2013, 06:55 PM #123

A less sharp object is not dull. And, I'm not sure if (for society?) sharp means honed to a fine grit, or a very thin bevel. You can touch a convex edge that feels dull, but it could very well shave like the finest razor, under conditions. And you can touch a knife with thin bevel, finished on 200 grit and say "wow that's sharp".

And, the whole "grit" thing, it is annoying. It's the particle size and shape that make something sharp, not the number of digits behind the word "grit". The 1 micron for Norton company is somewhere between 18 and 25k grit (anyone who knows, please specify), but for most Japanese companies, it's just 10k. That means, the Norton 8k has particles in the size of a 3-5k Japan made stone. Unfortunately, I haven't had the chance to compare an 8k Japanese stone with the Norton, to come to a conclusion.

I would suggest the use of the micron system to grade the stones, but then, we would need a way to compare the shape of the cutting particles, since ball shaped 10 micron particles would cut finer than 3 micron pyramid shaped particles. All this, to find a reliable method of comparing the cutting and polishing results of stones. Thinking about is PITA. Thinking in general is PITA. Living is a PITA. I should have been born an razor. Made from Wootz steel with fancy scales.

-

04-19-2013, 08:00 PM #124< Banned User >

- Join Date

- Mar 2013

- Location

- Thunder Bay

- Posts

- 200

Thanked: 12

-

04-19-2013, 10:37 PM #125There is no charge for Awesomeness

- Join Date

- Aug 2006

- Location

- Maleny, Australia

- Posts

- 7,977

- Blog Entries

- 3

Thanked: 1587

Perhaps this is a better explanation. By the way, this is the way I see it and it may not apply to everyone. It's a visualisation I use when I hone and seems to work.

There's a boundary point above which a razor will not cut hair. Below that point (the shave zone ... ), there is a very wide range of "sharpness". Perhaps surprisingly, something like a 1K hone will put most decent razors in the shave zone. I, and I know others as well, have shaved with a 1K edge just to see what it is like. It works but is not pleasant. I wouldn't call a razor in that condition dull, since it shaves. I'd call it rough.

), there is a very wide range of "sharpness". Perhaps surprisingly, something like a 1K hone will put most decent razors in the shave zone. I, and I know others as well, have shaved with a 1K edge just to see what it is like. It works but is not pleasant. I wouldn't call a razor in that condition dull, since it shaves. I'd call it rough.

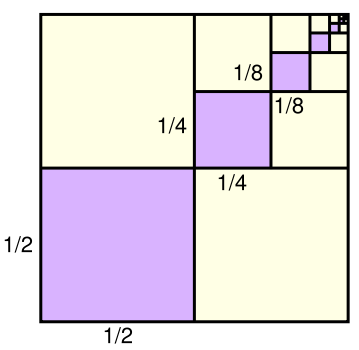

I guess the thing is how you visualise the grits - it isn't linear as you increase grit, it's geometric basically. Here's a picture I cribbed from Wikipedia showing 2D squares as opposed to 3D, but it does show how quickly the size drops:

The big square represents, say, the 1K particulates. The next a 2K, then 4K, 8K, 16K and so on.

Now if you are getting an edge that shaves (albeit roughly) off particulates the size of the big square (ie, the edge is narrow enough from scratches produced by something of that size), then hopefully you can see that any reduction in the width of the edge will be very slow going off particulates related to the size of the 3rd (4K), 4th (8K) etc squares. In other words yes, they will bring the sides of the edge closer together, but very very slowly.

These higher grits, IMO, primarily serve to make the sides of the bevel smoother and less craggy. It's what you see under a scope when you look at the bevel. This does in turn effect the edge since the sides and the edge connect. But it is such a small reduction relative to what has already happened on the 1K.

That's the way I think about it anyway. It works for me, but clearly it confuses others. So take it or leave it. I'd like to know how others think about it too.

James.<This signature intentionally left blank>

-

The Following User Says Thank You to Jimbo For This Useful Post:

Hirlau (04-19-2013)

-

04-20-2013, 12:25 AM #126

-

04-20-2013, 01:48 AM #127< Banned User >

- Join Date

- Mar 2013

- Location

- Thunder Bay

- Posts

- 200

Thanked: 12

If somebody is confused that a smaller grit is refining and smoothing (same thing right?) the edge of their razor... than maybe they would understand it like this.

You like mint? using the leaf is wonderful for cooking right? What if you used it's oil which is more concentrated requiring much less producing more bang for the amount and taking up less space.

We all use dish soap right? concentrated makes more with less.

We all like a razor that does it's job and cuts hair. So using the sharpest and smoothest edge producible - in short refined (?)will do the best job.

nomsayin?

-

04-20-2013, 01:54 AM #128< Banned User >

- Join Date

- Mar 2013

- Location

- Thunder Bay

- Posts

- 200

Thanked: 12

The edge would not be as smooth thus resulting in it being less sharp. Tried it on my new razor a few times and at first it was sharp and HHT proficient ff the 12k, than after going down in grits it did not produce the same sticky feeling from the TPT or the same results from numerous HHT's.

Take a piece of glass and run it across some micro fibre cloth (12k)... it's still smooth and scratchless. Than take that piece of glass and rub it across your driveway (4k) doesn't look the same right? Best comparison I could think of lol.

And to say that your blade doesn't dull after going down in grits is strange since those little particles just got bigger and your smooth edge just met resistance where before there was much less (1.5x -2x -w/e) because of them. Maybe not the whole length across depending on their spacing but...they will cause a smooth edge to say...become rigid.Last edited by LikesBBS; 04-20-2013 at 01:58 AM.

-

04-20-2013, 02:00 AM #129There is no charge for Awesomeness

- Join Date

- Aug 2006

- Location

- Maleny, Australia

- Posts

- 7,977

- Blog Entries

- 3

Thanked: 1587

Yeah, that's not bad. Except that, again, while you can just whack some concentrate into hot water and wash your dishes, you cannot just hone a dull razor on a 16K and expect to get a shaving edge in finite time. You do have to go through some kind of progression first, to get to the point where your "concentrate" will do something.

I kinda like the wood turning analogy too. Start with a tree, chop it down with a chainsaw and cut a chunk off. Get it into a rough shape with a saw. Turn it on a lathe. Get it smooth with sandpaper. The proper tools for each part of the job. Same with honing.

James.<This signature intentionally left blank>

-

04-20-2013, 02:07 AM #130Plausibly implausible

- Join Date

- May 2011

- Location

- Mount Torrens, South Australia

- Posts

- 5,979

Thanked: 485

I'm loving some of these analogies, very inventive...

"Now, say you had a goat. Well, it's not a cow is it? But if you had a very very very nice tea cup and brewed some tea for a VERY long time, well, you still wouldn't have some coffee, would you. See?"Stranger, if you passing meet me and desire to speak to me, why should you not speak to me? And why should I not speak to you?

Walt Whitman

237Likes

237Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks