Results 1 to 10 of 46

-

05-21-2013, 12:44 PM #1Learning something all the time...

- Join Date

- Jul 2012

- Location

- Central Missouri

- Posts

- 1,690

Thanked: 247 Anyone have experience with CTS-XHP

Anyone have experience with CTS-XHP

I'm playing with a new razor that a friend made from Carpenter Tool Steel's product known as XHP. I have honed it and shaved with it for a few days now and so far, it seems to be great stuff (achieves a very high level of sharpness and so far retains it quite well).

Has anyone used this steel and have any long term data?

-

05-22-2013, 06:01 AM #2

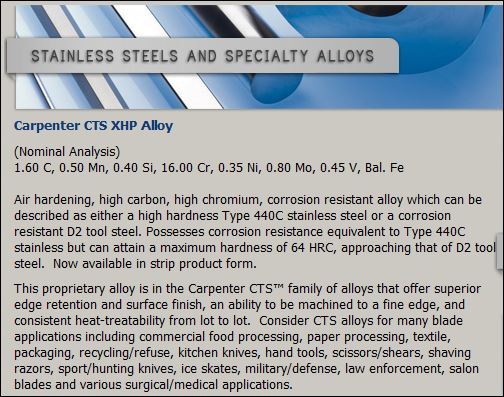

From searching on the web, it looks like it's pretty much the same with D2 steel, in performance and composition (with a little bit more Chromium, 16 vs 12%). If hardened the right way, it can hold a better edge than most razor steels, but grinding-forging-hardening it is difficult, and this drives the cost up for razor making. Also, if I'm right about its composition, it's a stainless steel. It sounds like you have a good razor.

-

05-22-2013, 03:53 PM #3Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

From their website:

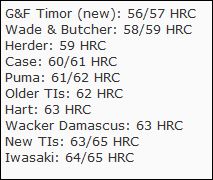

Max. 64 HRC - wouldn't like to hone too many of those!

Regards,

Neil

-

05-22-2013, 04:10 PM #4

-

05-22-2013, 04:48 PM #5

That's why I like Sigma select II stones, the hard ones anyway. I've got a kitchen knife made from HAP40. Nothing else works for it. Not even diamond plates.

Since we are in the topic, what's the HR hardness of a razor? Vintage, new, and stainless.

-

05-22-2013, 05:04 PM #6

Honestly I cannot remember exactly. I think a low end of 58 HRC or it is too soft. Mike Blue could give the exact numbers.

I haven't done it yet but I've been thinking of going for the Chosera 3k, 5k, and 10k for really hard razors. The norton 4/8 will get there eventually but it is a long slog.

With ATS-34 and with S30V I had to go to diamond plates to get them to the point of being ready to finish. Nice when they are done but a lot of sweat equity and elbow grease.

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

Vasilis (05-22-2013)

-

05-22-2013, 05:17 PM #7Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

See here, post #8.

The main points from that post:

Regards,

NeilLast edited by Neil Miller; 05-22-2013 at 05:23 PM. Reason: trouble with link and attached file

-

The Following User Says Thank You to Neil Miller For This Useful Post:

Vasilis (05-22-2013)

-

05-22-2013, 05:45 PM #8Learning something all the time...

- Join Date

- Jul 2012

- Location

- Central Missouri

- Posts

- 1,690

Thanked: 247

Yes, this stuff is pretty hard (I think ~62) but it is not overly difficult to hone. It may have been a PITA to produce the razor, but so far the results are impressive.

FWIW, it took about 20-30% more time to hone than a typical carbon steel (on Norton/Naniwa) which seems like a small price to pay for the edge it seems to support

-

05-22-2013, 06:18 PM #9

This sounds interesting.

Being a hone-nut I wouldn't mind terribly the added time.

What I get from this statement though, is that you seem to feel that this "super-steel" (I hate that expression) somehow takes, and potentially holds, a better edge than any carbon-steel razor?

I do have quite a few SS razors, and while most of them are really good, I haven't ever come across a ss razor that actually surpasses a good carbon razor.

They seem to loose the very crispness they can get off the hones/strops quite quickly for then to settle down on about 98% that will last forever..

FWIW Bjoernar

Bjoernar

Um, all of them, any of them that have been in front of me over all these years....

-

The Following User Says Thank You to Birnando For This Useful Post:

unit (05-22-2013)

-

05-22-2013, 06:24 PM #10

That's true. I don't have enough experience with razors and different hardness. But for other edged instruments like knives and wood working tools, (aside from the composition of the steel that can have a large effect on its edge retention for the same hardness) the edge from a 58-60RC knife, lasts twice as long as a 53-54 RC hardness edge. The same task, 5 degrees difference, but they have a big difference. A 50 HRC steel doesn't have such big difference from the 53-54. And above 60, the performance increases even more, but, try to test its toughness, and they brake almost like glass.

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote