Results 1 to 10 of 46

Threaded View

-

09-02-2009, 11:29 PM #16Coticule researcher

- Join Date

- Jan 2008

- Location

- Belgium

- Posts

- 1,872

Thanked: 1212

I don't comprehend that statement.

Taping the spine makes it slightly thicker. The resulting bevel has an angle that is slightly more obtuse. If we would compare the cross-section of both bevels, we would notice that the one cut with the thicker spine has a slightly wider base. Whether the difference of one layer is enough to make the edge more durable in a significant way, is something I highly doubt. (I believe we agree about that).

Yet I measure the bevel angle on every wedge I hone. And I have honed my share of poorly shaving wedges previously honed people that otherwise have no problem putting a good edge on a razor. In several cases the bevel angle was clearly out of range (under 15 or over 19 degrees) Correcting that, by adding, or alternatively not adding, tape always made a pleasant improvement.

I have seen wedges that were honed with at least 3 layers of tape and then convexed on a pasted strop (which only makes the angle even more obtuse), that should have in fact been honed with no, or maximum 1 layer. I have also seen wedges that had bevel angles of 12 degrees, and actually need 3 layers of tape to fall within range.

A bevel angle of 12 degrees easily wrinkles up during the shave. Let's see if I can find that picture back...

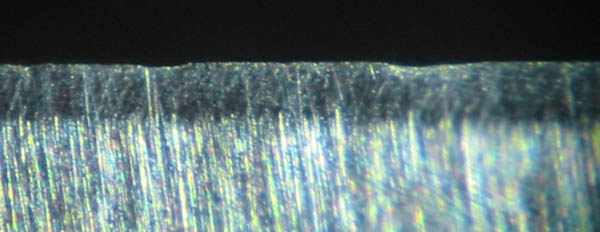

It's a "Sheffield Best" wedge, honed with one layer of tape, bevel angle approx. 12 degrees, edge deterioration after one shave. Please take my word for it, that the edge was perfectly straight before that shave.

An edge with a bevel angle of 20 degrees is so uncomfortable that it needs very high keenness not to pull on the whiskers. At the first signs of dulling it starts pulling heavily.

That is exactly my experience. Take the TI Silverwing. Allegedly very hard steel. But shaves like a dream if honed well. But I do not find it particularly having better edge retention that a razor of normal hardness. My beard easily causes microchips in the edge of a very hard razor. I think that's due to brittleness.

+1! I fully agreed.

A final question if I may: Is the purpose of tempering not to bring the RC down to a level that is considered acceptable as being hard enough to be stiff, but not so hard that the steel becomes too brittle for its purpose? So would tempering a hardened alloy that starts out at RC62, not be RC60 or so once it is properly tempered? Or doesn't it work that way?

Best regards,

Bart.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote