Results 31 to 40 of 46

Thread: Smooth Vs. Sharp

-

07-28-2017, 09:51 PM #31

I get what you are trying to say glen but I think a serrated knife compared to a razor is apples to oranges. Again, I get your point but then again I have had some "serrated" razor edges (microscopically of course) that gave a smooth and close shave. Of course if you take it to the Nth degree and try to shave with a serrated type severely chipped up edge I can't imagine it would be smooth so yes you are right to a point but I think when most people are looking at a straight edge say with no chipping and they have an uncomfortable shave and say it wasn't smooth or it was too sharp I tend to believe the opposite. It wasn't sharp enough.

A lot of this may be subjective and maybe it's semantics of smooth vs sharp but I don't think sharp stops happening at a certain level. As was stated above, it may be just a fraction of a micron but that's where it really develops in practice or becomes "smooth" for you other guys. :-)What a curse be a dull razor; what a prideful comfort a sharp one

-

07-28-2017, 10:55 PM #32At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,064

- Blog Entries

- 1

Thanked: 13249

Nope dead on comparison

You have to smooth them up from 2 directions

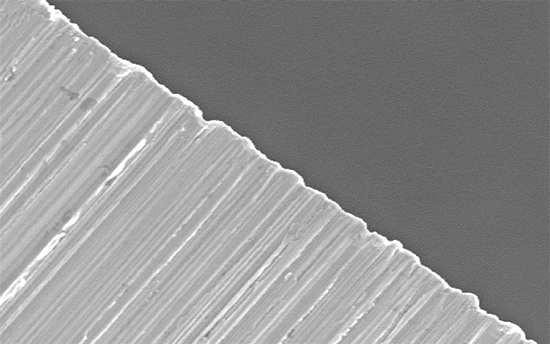

The sides of the bevel get smooth, and you eliminate the deeper Striations

Hopefully at the same time you are eliminating the un-even jaggedness of the very top of the sub-micron edge

When all that is smooth and even as possible you get a "Smooth" edge on your face.. It even accounts for the J-nat Haze and the Coticule Scratches...

Knife

Razor

The only thing difficult about honing is adjusting the pressure and stroke to accomplish what you need the steel to do.. The rest is simple and straight forwardLast edited by gssixgun; 07-28-2017 at 11:01 PM.

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

07-28-2017, 11:00 PM #33

If you have ever looked at an edge under 500X (and we all have) you would swear that the edge would be harsh and uncomfortable but it's not. Can you have sharp and not smooth? Sure but you can't have smooth without sharp unless you would compare it to shaving with a butter knife.

Which isn't shaving at all.

What a curse be a dull razor; what a prideful comfort a sharp one

Which isn't shaving at all.

What a curse be a dull razor; what a prideful comfort a sharp one

-

07-28-2017, 11:02 PM #34At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,064

- Blog Entries

- 1

Thanked: 13249 "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

07-28-2017, 11:22 PM #35

-

07-28-2017, 11:33 PM #36At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,064

- Blog Entries

- 1

Thanked: 13249 "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

07-28-2017, 11:43 PM #37Senior Member

- Join Date

- Jan 2008

- Location

- Northern California

- Posts

- 1,301

Thanked: 267

Serrated knife analogy is not that far off. I have been reading this thread forever and IMHO there is much food for thought. Hope this does not turn into a huge post but this is a huge topic.

IMHO an edge on a razor is made up of basically three things to look at when honing a razor.

1. Keeness.... defined by looking at the cross section of the edge. Both sides of the blade meet and how wide is that point determines the "keeness". Certain steels support different amounts of "keeness". Carbon steel, in our world probably, is probably that we can get. I own some white paper steel from Japan.

Simply incredible!

2. Bevel...... Once again looking at the cross section are the two ramps that meet at the point.

3. Thickness of the blade and the angle the Bevel is set at.

Firstly, I have a math and science background and my approach has always been very linear when it comes to honing razor edges.... WRONG OUTLOOK! By a linear approach, I mean that when I started honing I got a series of stones all the way to a 16K (0..92 micron) and eventually down to a 30K (0.49 micron). Somewhere along that road I used diamond paste down to 0.25 micron...... unbelievable keen and unbelievably tore my face up at the slightest provocation. Reason? The bevel and the edge are cut by diamonds and they cut the steel absolutely and are all about the same size leaving an edge that lookers like a serrated knife. Each point of the diamond cut was insanely keen and would, at the slightest mistake, simply go subterraneous and simply cut till you felt it.................NASTY CUTS specially if you were using scything sweeps. I ended up staying with the 30K stones. They gave pretty good shaves and how much finer can you get? Right? WRONG, to my amazement, once again! Japanese stones of a high quality would give you an unbelievably smooth and wonderful shave and were very forgiving. The reason is that natural stones have different sized particles and thus cut the steel very differently than man made particles.

The smoothness of the bevel of the razor has a tremendous effect about how smooth the shave is. That is why razor blade manufactures started coating the bevels with Teflon. It was to decrease friction as the hair is cleaving and starts sliding up the edge. The thickness of the blade is very important also and that is the single most important reason a honed razor will never cut as well as a thin blade that is precision manufactured.

Bevels from a Natural stone have a "sandblasted" matted look to them. The reason that it is smoother, when going up the bevel, the hair is actually only touching the very peaks of the rounded edges......less friction. Some of the new slurries made of Cubic Boron Nitride are excellent because they have particles that very closely approximated natural particles.

I hope this is not all to boring. I shave every day with a straight and, have since I started at this forum. I only hone to use the tool, not really for fun but, shaving with a straight is something that is just organically superior to any other type of shaving instrument that I have found.

Take Care,

Richard

-

07-28-2017, 11:54 PM #38

-

07-29-2017, 02:44 AM #39

Glen, I read our conversation again and I am clearly tired and not doing a good job explaining myself. You may very well be right. Stranger things have happened. I am sure what you are saying makes perfect sense to you. I just don't see it. Maybe someday down the road I will. I just don't think my face can feel that micro of a difference and am more inclined to think it is the blade ever so slightly tugging and pulling the hair that causes a "rough" shave. Maybe somehow we are both right.

One thing we can both agree on though is "Don't shave with a steak knife".

Good Night everyone What a curse be a dull razor; what a prideful comfort a sharp one

What a curse be a dull razor; what a prideful comfort a sharp one

-

07-29-2017, 05:25 AM #40

I can remember 2 Pumas that shaved the same but one had the nice smooth looking edge & the other did not. It's the only time I've felt this in decades of honing & shaving. They were finished on the same Jnat.

I wonder if the stone makes a difference & maybe the steel. I dunno, maybe if I pushed a 6 pass shave the raggedy edge looking one would have been less comfortable but for a normal 3 pass they were identical to me. I just accepted this one case as an exception to the rule.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

57Likes

57Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote