Results 31 to 40 of 72

-

01-08-2015, 12:37 PM #31Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

I used the angle of the razor (spine and edge) flat against the stone through all the grits (200 to get back to a slight smile, 400, 600, soft ark, black ark).

I figured looking at the examples that I have (youtube, Lynn Abram's, etc) may help but obviously trying something for the first time is no where near mastering it! That's why I asked. I used the 200 not because the edge needed it. Contrary there... I could tell right out of the package that this old razor was already fine enough to go straight to the black ark, or at the coursest, assuming the bevel needed touching up, the soft ark. I went to 200 mid this thread, not to refine the edge, but because I wanted to correct the geometry (had a few dips that kept it from being straight - I brought it to a slight smile which would have taken forever with anything finer than the 200).

BTW, I didn't mean to sound frustrated in my last post (#26). I looked back and it probably sounded that way. But I feel I am being misunderstood by several posters here. I'm aware that you don't sharpen/hone anything with 200. I used it not to sharpen but to reshape. The edge had some dips (frowns) in it. I used the course 200 and careful swooping passes to get these out. As in my original post, I used arks initially to hone this razor. After someone mentioned the frown I checked it with a straight edge (which of course isn't good for the edge in and of itself) and sure enough there were frowns/dips. ONLY because of this, I went to the 200 to get these out. That also said, I'm not trying to sound like I know what I'm doing... I've never sharpened a SR before this week! So I sure don't. But, I do understand the basics and I'm plenty familiar with grits and understand that you do not sharpen with 200. I used it to reshape. I'm sure whoever shapes these razors when new isn't using 2000 grit to do it. Neither would I.Last edited by 777funk; 01-08-2015 at 01:21 PM.

-

01-08-2015, 02:26 PM #32Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“That would be a big jump, no I brought it back up through to the black (200, 300, 400, 600, soft ark, then black)”

Assuming this is what you have available, these are all natural stones, except the 600 diamond plate?

Post photos of your stones.

I have never use anything courser than a 600 and that is for removing ¼ in size chips. 1K for 99 percent of all work, anything courser will leave deep stria that will have to be removed and may cause chipping down the road in the finer grits.

Unless you can grit rate the Arks and get one in the 800 -1k range, (all natural stone are different, especially Arks) your best bet is to buy a synthetic progression 1, 4 & 8k and lap you stones, on 325 wet and dry.

Tape the spine with 2 layers of tape, to protect it and set the bevel on the 1k, stay on the 1K doing circles or half laps in sets of 20, until the bevel is set and you have created a…edge, a sharp even edge.

You first have to make an edge, (hone the two bevels flat so they meet in a straight, burr free edge). And do so at 800 to 1k, anything courser will cause chipping later in the finish grits of the progression.

Anything less and you are bevel setting for hours especially, after a 200 grit honing all that stria has to be removed.

Look straight down at the edge with magnification and strong light, if you see reflections, the bevels are not meeting. Stay on the 1k until you no longer see light reflecting back. Change you tape frequently, you will burn through it and ruin the spine.

Diamond and novices are notorious for causing chipping edges, then the edge must be removed and start over.

An experienced honer can bevel set with a Washita and finish on a Surgical Black with the right stones and properly prepared for razors and several hundreds of laps.

I know it can be frustrating to have folks tell you, you’re doing it wrong, but when we say honing a razor is different than a knife or tool… it is.

Add to all that, you are going to put the edge to your face, it has to be extremely sharp and comfortable. Finishing on 8K grits or higher with a very lite touch will give you comfort if the bevel and edge have a good foundation, a properly established bevel and progression or the edge will not hold and crumble or chip.

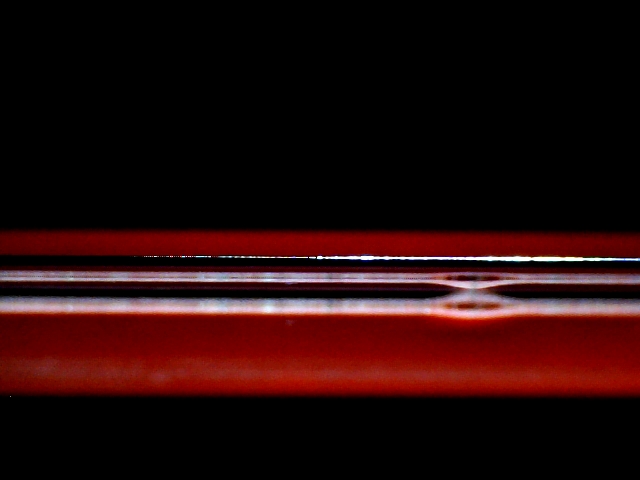

Here is bevel that is partially set, the white line on the right is not set, the left side is. Once you no longer see white lite reflecting the bevels are meeting, you cannot see the edge, it is that thin. The red is tape.

-

The Following 3 Users Say Thank You to Euclid440 For This Useful Post:

Anthony1954 (01-08-2015), Moosiker (01-13-2015), QXDPC (03-01-2015)

-

01-08-2015, 02:35 PM #33

Maybe it's wise to learn how to shave with a "honemeister" honed blade and get a second blade to learn the honing part.

“We are what we repeatedly do. Greatness then, is not an act, but a habit”

― Aristotle

-

01-08-2015, 02:43 PM #34Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

The picture you posted is basic and applies to all sharpening. If I could see a reflection looking straight onto the edge/bevel, the blade wouldn't cut anything (maybe butter). There is no reflection coming from my edge and it cuts hair. I've even shaved with it but it feels like a disposable that's been used a few times. It's sharp but not quite sharp enough. I can easily shave chest hair or an arm with it, so it is sharp.

As far as the grits go, (I feel like I'm echoing myself), I used the 200 ONLY to reshape since the blade had some frowns. This is an antique razor we're talking about. It was out of shape in the litteral sense of the word. I realize that you wouldn't normally use anything courser than 600 or even 1000 unless something was bad wrong. This is exactly what I'm saying... I had to reshape the blade.

My stones are diamond up to 1000 (Diasharp is my 1000, Harbor Freight on the courser ones), Hall's Pro Edge for the two Ark stones (soft and Surgical Black).

-

01-08-2015, 03:29 PM #35Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Now were getting somewhere…

Diamonds are very aggressive especially in low grits and cause deep stria that in turn cause a rough edge.

ALL that stria needs to be removed from the bevel with a stone that is not a Diamond Plate and is in the 800 to 1K grit range.

ALL the 1K needs to be removed with a 4K grit stone, then ALL the 4k needs to be removed with an 8k stone.

You can try with your Soft Ark doing circles, 20 set at a time, be prepared you will have to do several hundred, depending on the grit of your soft ark.

Once you remove the deep stria, switch to smooth lite X laps do a few hundred more.

How large are your Ark stones?

Have your Arks been lapped flat?

-

01-08-2015, 03:36 PM #36Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

They're pretty big (4x8 I believe). And they were factory lapped. I haven't worn them to the point that they've hollowed yet. I started with oils because they didn't require as much flattening as the wet abrasive impregneted stones. But the tradeoff is that they're not graded by grit and they are a little slow cutting.

-

01-08-2015, 03:55 PM #37

1. Naturals are NEVER graded by grit.

2. If you haven't lapped them, they are not flat enough for razors.The easy road is rarely rewarding.

-

The Following User Says Thank You to Splashone For This Useful Post:

777funk (01-08-2015)

-

01-08-2015, 03:58 PM #38

-

01-08-2015, 04:01 PM #39Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So the size is good

Probably 3X8. Any natural does not have a grit because no one was there filtering the grit when they were created, so they contain random grits.

You can rate them as grit equivalent, by comparing to a known grit stria from a synthetic stone. But that is what they cut like now, as they wear that may change.

Factory flat is not flat, some are close, usually not.

Mark a pencil grid on the stone and lap on a sheet of 220 grit Wet and Dry on a cookie sheet on a flat surface.

If it is not flat, re-grid and lap flat on 60 or 80 grit wet & dry with soapy water and lots of pressure. I use the floor and your body weight.

60 or 80 grit Loose Silicone Carbide is faster and inexpensive from Gotgrit.com, 5-6 bucks.

Use a progression up to 1-2k wet and dry.

Lapping Arks is a lot of work. Here again flatness of a stone is different than tools and knives and much more critical, if not flat, as the stone abrades rougher pockets of grits can cause your edge to go backwards erasing all you hard honing work.

Another reason for learning on Synthetics.

Do the same for the Black Ark, then burnish with hard flat carbon steel. A wide chisel or large butcher knife, water and soap or oil and lots of pressure.

You are looking for a glass smooth flat finish, it will take hundreds of laps.

Then hone your razor.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

777funk (01-08-2015)

-

01-08-2015, 04:14 PM #40Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

Right and all of my grit statements made were regarding the diamond blocks. I mentioned the black arkie is likely ballpark to 3-4k (compared to sharpening tools using similar wet/dry sandpaper taped to a granite tile).

[/QUOTE]

Unless they were lapped dead flat by the manufacturer (Halls said they were when I purchased them). I'm sure I looked at them with a straight edge when purchased, but I'll check again.

54Likes

54Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote