Results 51 to 60 of 72

-

01-09-2015, 03:42 AM #51Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Funk, your black may still be a finisher, Blacks and translucent do not leave a traditional stria, but a kasumi, hazy pattern, which is why you cannot grit equivalent rate them. They will or can finish much higher than their rating and as said can be burnished to finish even higher.

You have to get rid of all the stria from 200 up to 1k diamond before you can even attempt to finish with the Black.

Are you considering purchasing a new stone or are you trying to accomplish this with what you have?

What kind and power, of magnification do you have?

If you are determine to do this with your existing stones, try this…

Double tape the spine and do circles on your 1k Dia Sharp in sets of 20 until you remove all the low grit stria. Do not use a lot of pressure, water and a drop of liquid dish soap will help, it should not take too long, but you do not want to create deep 1K stria.

Once you remove all the deep stria, do X laps, on water with weight of the blade until you get an even 1K stria pattern.

Lap the soft Ark on an 80 grit belt, for arks grid mark them with a Sharpie, pencil washes off too quickly. Work up to a 400 or 600 grit progression.

Now do circles on the Soft Ark until all the 1k stria is removed. Then lightly joint the edge on the corner of the soft ark. Just lightly drag the edge on the corner of the stone. This will straighten the edge.

Now do x laps until the bevels come together again and an even stria pattern is on the bevels. This may take several hundred laps. You may not get all the 1K stria off, you Soft Ark may be too course. Either way you will reduce the 1K stria and straighten the edge.

You should have a straight edge and even shallow stria pattern on the bevels.

Lap your Black Ark as flat and smooth as possible. Now remove all the Soft Ark stria with the Black Ark, here again hundreds of laps.

As said a Norton 4/8 combo stone would make your life so much easier.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

777funk (01-09-2015)

-

01-12-2015, 12:35 AM #52Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Funk, so what happened?

Put the best edge you can on it, then send it to me. I’ll photograph the edge with a USB scope and re-hone it for you…

See what you think.

PM me.

Marty

-

The Following User Says Thank You to Euclid440 For This Useful Post:

777funk (01-13-2015)

-

01-13-2015, 04:50 AM #53Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

Well, I've not given up. I'm still working on getting where it needs to be and the latest...

...

Well something bad happened tonight! I read a tutorial on making a Gold Dollar into a useable straight and the guy had some pointers I figured I'd use on my Wade & Butcher. Anyways, I noticed that the handle (near the edge) was making the blade not lay flat to the stone. I noticed this earlier and just tried to avoid riding the handle onto the stone when honing. I took the handle to the grinder and brought it shy of the blade surface. Then I noticed the spine (sides) were slightly warped to where one side would rock on the stone when sharpening and the other had an arch. So I tried to straighten it and... SNAP! These are hardened to the point that bending isn't going to happen. So now I have a 1 1/4" length to shave with. The plus side is that it's not as much to sharpen and strop so it goes a little quicker. Still not cutting as well as I'd like but the shorter length doesn't have a rock to it and seems to sharpen better now than it did before. I also flattened my arkies.

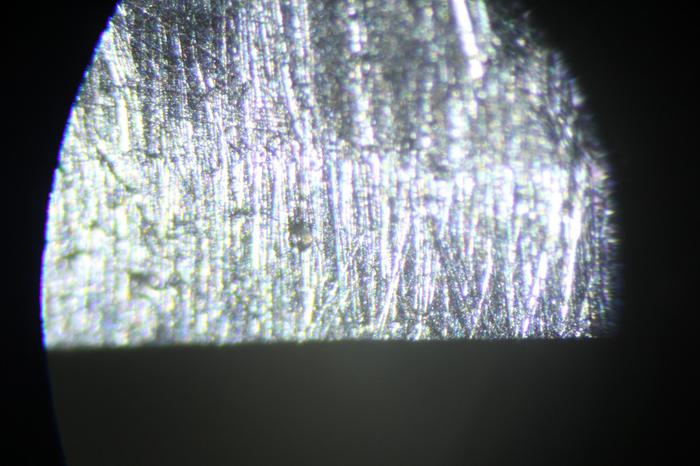

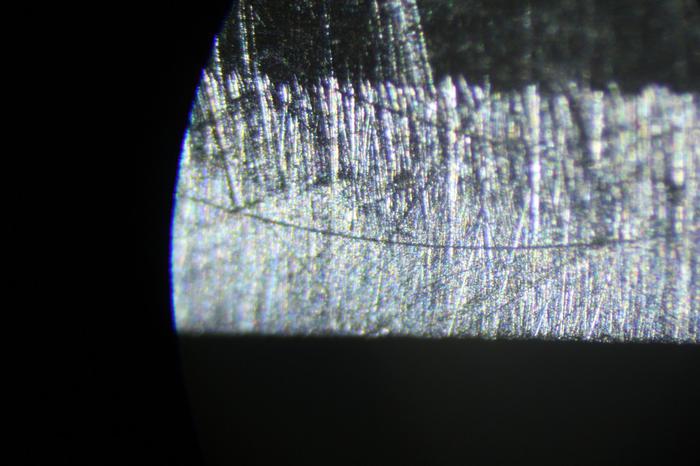

Here's a picture of 50x magnification (microscope).

Before Stropping (1000 DMT, Black Arkie) - (50x mag on microscope):

After 50 (IIRC) Passes on a smooth Leather Strop (50x mag on microscope):

I will be sending it off to a generous member who's offered to inspect. I appreciate it to both who've offered! I'll be buying another straight and seeing if maybe it works out better. Hopefully the next one will have less issues and I'll be able to get it to do what I want it to do.

This one is shaving but still is a little rough feeling on my face. I can tell I've got some small burrs that aren't comfortable. BUT... progress! It's cutting better and I'm getting close. Works great for edging side burns. Wow! Don't think I've ever seen anything this clean.Last edited by 777funk; 01-13-2015 at 05:02 AM.

-

01-13-2015, 05:12 AM #54Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Does look better, but you still need a mid-grit stone.

You’re not the first one to break a razor, it is how we learn… unfortunately…

-

01-13-2015, 12:32 PM #55

-

01-13-2015, 01:22 PM #56Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

Euclid, I think this is the scratch pattern from the black arkie. I ran it way longer than normal to make sure it was what I was seeing. One thing to remember is that this is at 50x magnification in a microscope. I think most Loups are 10x. So it will definitely exaggerate things on 50 power. I did notice that the 3000 grit wet/dry left a better finish to the naked eye (mirror) than the black arkie. I'd like to see that under the scope.

For future reference if I see a bend in the spine, is there a way to correct it besides... bend.................. SNAP!! lol

-

01-13-2015, 02:05 PM #57Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Most razors are not straight, but it does not really matter, you can hone them anyway, it just takes some maneuvering of the blade so it is in contact with the stone using an X stroke.

Unless the razor is bent so bad that it hits the scales it is not necessary.

Charlie Lewis has a good video on how to do it

-

01-13-2015, 02:33 PM #58Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

Ahh! Interesting. You know... I didn't even think about temper when I tried to bend it, until it was too late! Now I know.

My razor wasn't crooked on the tang though. It was actually the spine. Maybe the X pattern would still allow it to sharpen evenly. I'd guess it was about .030" of a bend right in the center of the spine and wouldn't allow it to lay flat on the hone.

-

01-13-2015, 03:10 PM #59

If the spine is bent, the spine is bent. There is no way to get around that one. You should also be very mindful of what you are doing with grinding and motorized polishing of razors. You can ruin the temper at fairly low temps. Basically, if the steel changes color, its toast.

For 50X those scratches are HUGE. A nice edge appears mostly smooth with some light scratches at 100X.Last edited by Splashone; 01-13-2015 at 03:13 PM.

The easy road is rarely rewarding.

-

01-13-2015, 03:22 PM #60Member

- Join Date

- Jan 2015

- Posts

- 32

Thanked: 0

54Likes

54Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote