Results 1,851 to 1,860 of 20602

Thread: What are you working on?

-

02-12-2016, 01:39 AM #1851Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

Nice work Roy. Vertical lathes work, you just have to deal with the ups and downs more.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

cudarunner (02-12-2016)

-

02-12-2016, 01:50 AM #1852Member

- Join Date

- Dec 2015

- Location

- Ohio

- Posts

- 89

Thanked: 26

Well I got this blue steel for about 15.00. It wasn't in horrible shape but needed new scales and a little love on the blade as you can see. I cleaned up the blade going from 320/ 800 grit sandpaper. I cut the scales out of a block of cocobola wood and I'm up to 400 grit on those. I'm only going to 600 maybe 800 grit. I'm still trying to decide if I'm going to finish with CA or go with poly. This will be my thirteenth razor I've done. Still new at it.

The pics are original condition and where I'm at now. More to come!

-

02-12-2016, 02:01 AM #1853Member

- Join Date

- Dec 2015

- Location

- Ohio

- Posts

- 89

Thanked: 26 Horn scale in need of rebuild

Horn scale in need of rebuild

My other project are the horn scales from the FBU chopper I posted in butchered blade. I was showen a way to fill the cracks and the peeling at the pivot end with CA and ground horn. Hope it comes out right.

here is a big thumbs up/thank you to outback for all the help.

-

02-12-2016, 02:04 AM #1854Member

- Join Date

- Dec 2015

- Location

- Ohio

- Posts

- 89

Thanked: 26

I was going to fix them up and start a need " needs a blade " stash.

-

02-12-2016, 02:04 AM #1855

You new fellas seem to come up with some radical designs!

Did you save the old scales?"Don't be stubborn. You are missing out."

I rest my case.

-

02-12-2016, 02:11 AM #1856Member

- Join Date

- Dec 2015

- Location

- Ohio

- Posts

- 89

Thanked: 26

Yes, the old scales had some funky smugma on them. it also had a crack on the pivot end. I got the smugma off and my next step is to ca the crack and see if there in any condition to move forward with the clean up

-

02-12-2016, 02:38 AM #1857Senior Member

- Join Date

- Dec 2015

- Location

- North Dakota

- Posts

- 1,455

Thanked: 250

-

02-12-2016, 02:58 AM #1858Member

- Join Date

- Dec 2015

- Location

- Ohio

- Posts

- 89

Thanked: 26

Ha ha ha!!!!

Well that ( smugma) hopefully would have flaked off by now. But anything unidentified I call smugma. It was stubborn but it came off.

-

02-12-2016, 03:06 AM #1859

Ok this is as far as I'm going tonight!

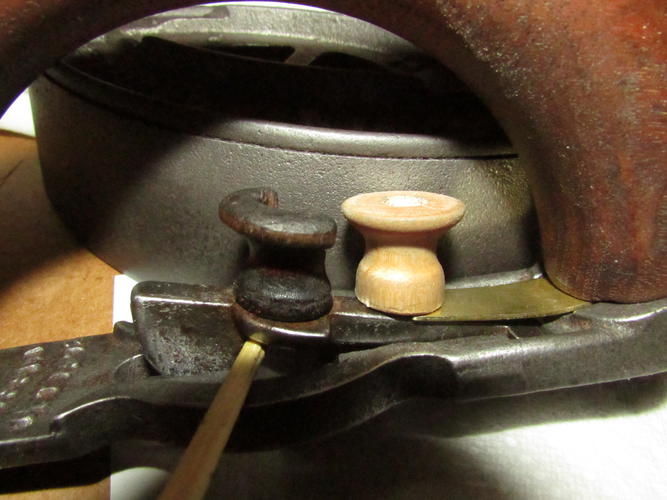

Here's the best I could do for side by side pics of the knobs;

And here's a decent pic of how the original knob is attached/peened to the frame;

Well this is about as good as it's going to get. Not a perfect match but decent. As you can see there is a cone that the wood slide down, I'm presuming that the base of the cone and the hole in the wood were close to being the same.

I'm planning on using some JB Weld at the base and then tapping the copper washer down to keep it all straight. I've done a couple of trial fits using the deep socket to gently drive the washer on and it works well. Then when the epoxy has set for a day or two I'll go ahead and peen the top using some punches that my dads. I will try to anneal just the tip of the cone before peening.

Now to pick up some stain and 'try' to get it close to the handle.

Last edited by cudarunner; 02-12-2016 at 06:40 PM.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

sharptonn (02-12-2016)

-

02-12-2016, 03:09 AM #1860

Thats what I love about them Tom. But he/ I need your old school knowledge& wisdom an help to pull off our work. New scale designs are the only "new" thing that us newbies bring. All other factors must stay the same to have a great shave. Grinds and steel are way over our heads. Scale shapes allows new fellas to put there own touch to a blade.

Your only as good as your last hone job.

-

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote