Results 2,921 to 2,930 of 20573

Thread: What are you working on?

-

04-11-2016, 03:10 AM #2921

-

The Following User Says Thank You to engine46 For This Useful Post:

outback (04-11-2016)

-

04-11-2016, 03:12 AM #2922

-

04-11-2016, 06:50 PM #2923

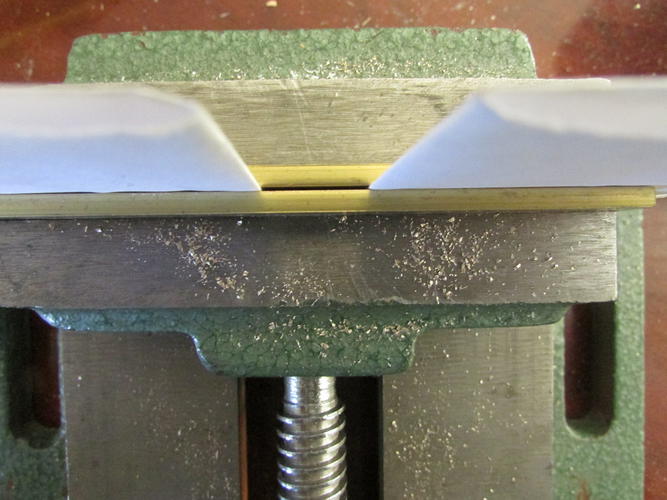

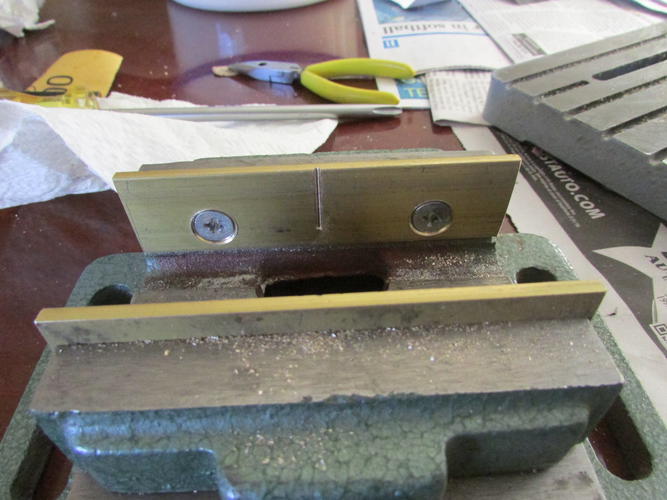

Well I woke this morning with the notion that my very expensive vice needed brass jaws so I took a piece of 1" tall by 1/8" thick scrap brass bar that had been in my dad's tool box for the last 18 years when I inherited it and made a pair. While they are a little too tall, that's fine with me as I wasn't going to die of old age trying to saw and then file them by hand to the same height as the originals. Plus they aren't going to be holding much more than pins and razors.

I used one of dad's centering punches and marked where the holes should be then I pre-drilled them. Since they aren't designed to be used in a drill press the lathe counter sink was a pain to get centered and it chattered badly but it got the rough-out done. I finished up with a tapered abrasive cone (again it was dad's) and they were nice and smooth and the screws recessed perfectly.

Anyway here's my build for today.

Dad's countersink:

The brass installed;

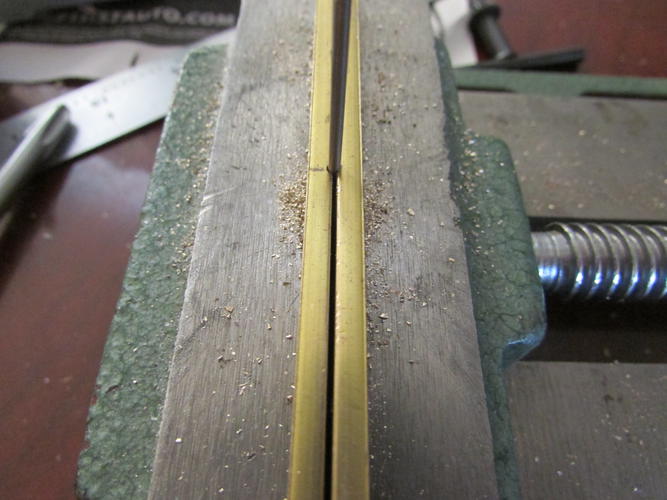

However I'm Anal and just as I had with the originals, I made a guide to hold pins at a 90 deg angle. But this time I only drilled down 3/4" so that I could always know how long they would be. If I need longer I can eyeball it. So much for being anal.

Well back to being Anal; I folded some of my computer paper into 3rd's to make a little room so that there would be something to hold the rod. A .012 feeler gauge slides nicely between the jaws.

Here's after drilling with a 1/16" drill bit;

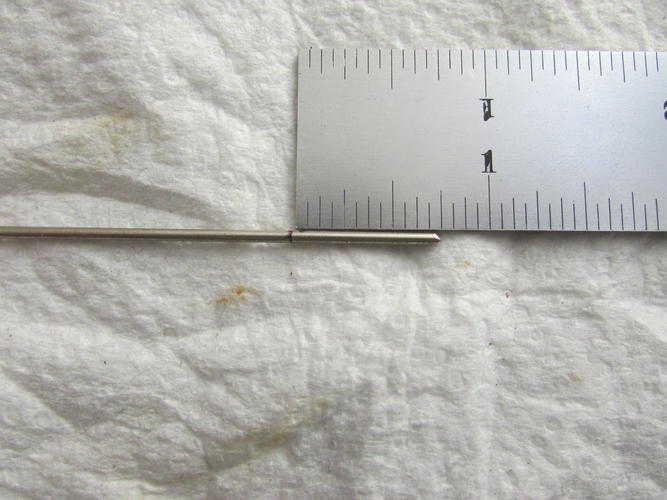

And with a rod held in place. Note that there is a space between the jaws. That's why I shimmed with the paper. If I were to have just drilled with the jaws fully in contact then there wouldn't be anything to hold the rod.

I'm not real concerned about the durability as the only impact on the drilled hole will be starting a peen on a rod and with the jaws tightened and the 'tap, tap, tap' any impact will be minimal.

And by using a fine point sharpie and inserting a rod then marking at the top of the brass jaws it's right at 3/4"'s long.

Maybe I'll get a little more Anal in a day or so and drill down another 1/8" or so Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

-

04-11-2016, 07:18 PM #2924Member

- Join Date

- Feb 2016

- Location

- Fla

- Posts

- 94

Thanked: 10

good job on the vice jaws

Dennis

-

04-11-2016, 07:31 PM #2925

That looks great, Roy!

So I am playing with Gencos. I have a nice double-ground silver steel Geneva with a 25 in the pyramid, 6/8 and in great condition. Figure to give it a nicer set of clothes. Digging around in the ivory pile...........

Anyone ever seen a Genco in ivory? I remember Pixelfixed once scaled a Dovo in it!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

04-11-2016, 07:52 PM #2926

-

04-11-2016, 08:04 PM #2927

Well, these Silver-steel ones are said to be quite good. It definitely has a more pronounced double-grind than any of the other's I have.

Here we go! Found this set with nice patterning, thicker than most from Sheffield with beveled edges. The bottom is pinned with collars.

Fits great!

Also, a Genco Easy Aces project has been rediscovered. Two razors, junk scales on one, junk blade on the other.

I think combined, one good one should be possible.

Lots of cleaning/polishing to go!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

04-11-2016, 09:06 PM #2928Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Couple of clean ups arrived today. A globusman #12 with a nice inlay and an H Diamond, the Diamond 5072 will need new skins, but overall, not bad condition.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

04-11-2016, 10:51 PM #2929

-

04-11-2016, 11:39 PM #2930

Well, I wound up spending lots of time on the scales. The Silver Steel was too nice to do anything but hand-polish on. The Easy Aces had lots of fine pitting and is very thin, so a little sanding with CroOx and Crocus, a bit of buffer. Called them done. Did my best to emulate the bottom pins on both, using stacks on the ivory.

Turned out fine, I think.

Onward to the hones!"Don't be stubborn. You are missing out."

I rest my case.

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

.

.

Reply With Quote

Reply With Quote