Results 11 to 20 of 59

-

09-19-2016, 01:26 AM #11

Thanks for the encouragement fellas. I'm in the long part of the restoration where it's just carefully getting to the bottom of the pits. Makes for a bit of a boring thread at this point but things will be more interesting after the pitting on the blade faces is resolved. The steel is very hard and is taking it's sweet old time. 3 more hours today, total 6.5 hours sanding the blade so far, still with 150 grit.

-

The Following 2 Users Say Thank You to xiaotuzi For This Useful Post:

ScoutHikerDad (09-25-2016), sharptonn (09-24-2016)

-

09-19-2016, 03:47 AM #12

Awesome job, keep up the great work! A daunting task but we'll worth the wait. Look forward to the finished product.

Sent from my SM-G900V using Tapatalk

-

The Following User Says Thank You to Phil129 For This Useful Post:

xiaotuzi (09-19-2016)

-

09-22-2016, 11:36 PM #13

So...Any progress?

-

09-23-2016, 12:01 AM #14

I've been making steady (albeit slow) progress. Here the pits are almost out of the blade faces, but it's the last ones that seem to be the hardest little buggers.

Then finally the pits are out of the blade faces. I managed to maintain a smooth even surface from what I can tell so far. So the blade faces have scratch from 150 grit right now. It took something like 12 hours to this point.

Next I will focus on the spine, tang, tail and notch getting them all pit free at 150 grit. I do not do anything to the maker's mark - that will be done separately using minimal touches because it is not a very deep mark. I tape the edge for safety. Sometimes I use a small diamond file in these areas as long as it never contacts the blade faces or maker's mark. After pitting is out on these areas I will finally at last be able to start working through the grits 220, 400, 600, and on up. I'm having fun but I realize this thread so far is like watching paint dry

-

The Following 2 Users Say Thank You to xiaotuzi For This Useful Post:

ScoutHikerDad (09-25-2016), sharptonn (09-29-2016)

-

09-24-2016, 01:31 AM #15

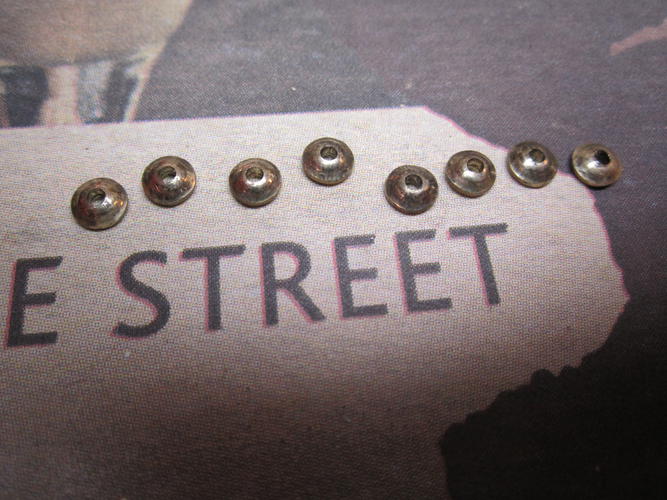

Took a break from the blade work and made solid brass dome collars today. I made a set for me and a set for a friend of mine. I basically use the method described in this thread... http://straightrazorpalace.com/works...-vlad-how.html

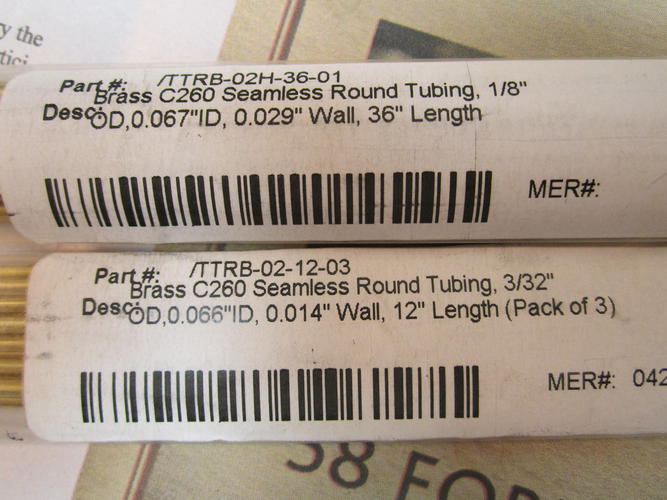

I am set up to make two sizes, large and small using these size brass tubes found on Amazon

These are my tools for making collars. Steel rod drilled out and cupped for different sizes along with a mandrel made from a roofing nail.

I cut the tubing and put the pieces in the jig using a snapped off piece of 1/16 drill bit as a post.

Then I hammer the jig and make the domes.

Then I dish out the top to allow for pin to set flush, use the mandrel in a dremel and progress through high grit sandpapers and lapping paste on cloth scrap to polish. Yep, these will do nicely..

-

The Following 9 Users Say Thank You to xiaotuzi For This Useful Post:

aaron1234 (09-24-2016), ejmolitor37 (09-26-2016), gabrielcr78 (11-17-2017), MikeB52 (11-13-2016), MrZ (11-17-2017), outback (09-24-2016), Panama60 (09-24-2016), ScoutHikerDad (09-25-2016), sharptonn (09-24-2016)

-

09-24-2016, 01:37 AM #16

Those come out pretty sweet..!!! Gives me idee'rs.

Mike

-

The Following User Says Thank You to outback For This Useful Post:

xiaotuzi (09-24-2016)

-

09-24-2016, 01:47 AM #17

Man, I totally love the doing more with less!

Awesome!

-

The Following User Says Thank You to sharptonn For This Useful Post:

xiaotuzi (09-24-2016)

-

09-24-2016, 01:48 AM #18

Yes! Very nice work, guess I know what my next project is

Sent from my SM-G900V using Tapatalk

-

The Following User Says Thank You to Phil129 For This Useful Post:

xiaotuzi (09-24-2016)

-

09-24-2016, 03:44 AM #19

Lookin' fiiiiine. Keep puttin' out that great work tuzi!

-

The Following User Says Thank You to dinnermint For This Useful Post:

xiaotuzi (09-24-2016)

-

09-25-2016, 08:52 PM #20

Wow, your patience and skill with the hand sanding are incredible, not to mention those domed collars! I can't wait to see where this goes!

(Oh, and now that I know your name is Garrison, it will spare me the awkwardness of referring to your as Xiaotuzi-pray tell, where did you get that forum handle? It sounds like the name of some warrior chieftan!).

Aaron

-

The Following User Says Thank You to ScoutHikerDad For This Useful Post:

xiaotuzi (09-26-2016)

244Likes

244Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote