Results 31 to 40 of 43

Thread: 4/8 Scales

-

11-01-2018, 02:10 PM #31

Others have mentioned, and I'll agree, that G-10 is hard to beat for liner. My preference would be to never work with it, though I haven't come across anything as good for liners.

It comes in plenty of colors, including white. I dye the epoxy to match the color of the liner, using Mixol dye and it has really made them pop.https://hendrixclassics.com/

http://HendrixClassicsCo.etsy.com

https://www.facebook.com/HendrixClassics

-

11-01-2018, 02:29 PM #32

Nice! I bet it looks awesome. Like I said, I have quite a bit of it. I might consider it, but I'm really stuck on the liner being metal for now. Not sure why I'm so married to that idea other than I hate a scale that shrinks. And I mean hate lol.

We'll know soon enough how well it's all going to work out. I got my order in last night, and I'm stoked!! The 0.01 Nickel is stupid malleable, but next to the 1/16th paper, I'm thinking I'm going to have one sweet winning combo that'll be both thin and ridged! I'm pumped.

Now if my dang washers would only show up, I could make a prototype this weekend and let all-you-all be the judges. Hope they get in by Friday!!David

-

11-03-2018, 09:22 PM #33

UPDATE:

ok! All the materials are in, come hell or high water, the scales will be made in the next couple of weeks, or month at the most.

Right now it’s R&D time. Using a failed previous attempt of a scale, I tried a couple of textures.

At the end of the day, I can see a bunch of looks looking great, but decided on the golf ball look.

I’ve pretty much settled on the scale shape mimicking “A” in post #1, and stealing spazola‘s texturing technique (sort of) as seen in post #20.

As much as I’d have loved to have used a white spacer, I think a black one will be more appropriate.

Wish me luck.Last edited by earcutter; 11-03-2018 at 09:25 PM.

David

-

11-03-2018, 09:30 PM #34Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

I use an engravers block with a hardwood block and double sided tape. It gives me infinite variability in the position of the piece and allows me serious control with both chisels and Dremel. You can get more control with a swivel vice than a fixed one. Engravers block or vices are a wee bit pricey.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

earcutter (11-03-2018)

-

11-04-2018, 02:36 PM #35

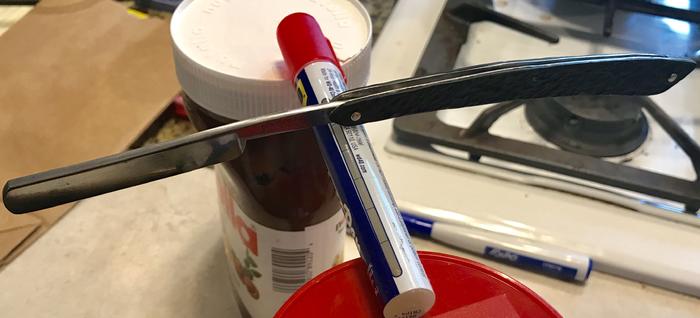

This is a Prototype!

This is a Prototype!

I canít stress that enough. I banged this together to see if I liked how all the pieces came together with my shortest blade. Look, you might not see it, but the thing is hardly sanded, one scale is actually cracked in half when I tried to stamp my name on the inside, the pins arenít even... well you get it. Itís a prototype!!

Here it is.

So itís settled. I love the ĒroughedĒ or whatever you call it scales. Textured. This IS how Iíll be moving forward.

That said, I need to make sure NOT to use the engraver that makes the ďpot marksĒ sideways, otherwise itíll ďrun.Ē This is why I do a prototype. I learned a ton!! Straight up and down is way slower though.

At first I started to think Iíd hate the silver liner. I didnít think it looked as classy as the brass Iíve used in the past, but iíve been converted because that .01 is SO thin! I love it. But sanding it vs brass is way more challenging. Way more. You need to go really fine with it. But THIN is IN!

The most important thing though is the balance. With a small 4/8, that can be a challenge!

This is why Iím SO stoked with the prototype! The balance is perfect! I completely lucked out! Iím stoked!

Two major things I learned though.

A. Donít be cheap. Leave room, sand more. Iíll need to oreder a couple more sheets of the nickel. Sigh.

B. Figure out what you want to do - send it to a pro.

PS. How do you darken paper Macarta? Could I put crazy glue on it? Thanks.Last edited by earcutter; 11-04-2018 at 02:45 PM.

David

-

11-04-2018, 03:03 PM #36Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

i like it.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

earcutter (11-04-2018)

-

11-04-2018, 05:53 PM #37At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,034

- Blog Entries

- 1

Thanked: 13247

Balance -

It becomes most important while Stropping

Sortta important while honing

Pretty much adjustable while shaving

Most tools and Vintage SR balance to the point where you hold them in our SR's that is the tang,, Do not just believe what I am saying, go pick up your Vintage razors and test it..

I observed those old farts had been doing it for 100's of years so I figured maybe they knew something so I copied them,

It also isn't that hard to do, also you will notice PDQ that the Vintage razors almost always match the Height of the Tang and the Height of the Scales at the pivot. This allows for seemless rotation while Stropping..

All of this info is in the Workshop Sticky it isn't new, it is just observations when you look at Vintage builds, same as the Wedge angle matching the Tang angle, and the flex built into the scales as they open and close..

Just some hints I have found useful over the years"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

The Following User Says Thank You to gssixgun For This Useful Post:

earcutter (11-04-2018)

-

11-04-2018, 07:02 PM #38

I've brought this up in the past but didn't really get any conclusions..

Why is brass used as spacers? I know it will last longer being that it is a more noble metal than steel, and I'm wondering if the decision was made to allow some sacrifice of the tang to prolong the life of the spacer.

This came to mind as I was wondering what spacers you are using. Perhaps nylon would be best as both nickel and brass are more noble than steel and it may allow more protection from pivot rust.

Even still, the nickel silver pins would be pulling away from the steel and maybe zinc washers would be the only real protection from pivot rust besides the obvious keeping it dry.

Just a thought.

I've used zinc washers, don't know how long they would last, probably a long time, but they will act as sacrificial anodes and be an added protection.

Anyway, it's always an idea that pops in my head when thinking about metal liners and such.ďYou must unlearn what you have learned.Ē

Ė Yoda

-

11-04-2018, 07:36 PM #39

On my prototype, with my shortest blade:

Dang it! I’m just forward of the pin. Which kind of bites. Feels great though oddly enough.

I’m doing my longest blade now. That’ll make a difference. I’ll let you know. Using the same scale for 7 razors will always be a compromise .

David

.

David

-

11-04-2018, 07:54 PM #40

IMO, it's not that critical, David. If one feels good in the mockup, it will be fine.

Curious....Why do you need liners with the linen micarta?

-

The Following User Says Thank You to sharptonn For This Useful Post:

earcutter (11-04-2018)

99Likes

99Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote