Results 1 to 10 of 72

-

03-04-2010, 05:29 AM #1At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,210

- Blog Entries

- 1

Thanked: 13250 Walking a W&B though the Buffers - Illustrated

Walking a W&B though the Buffers - Illustrated

I decided to take pics of this W&B "American" Razor as I tried out my new buffer bench...

These are the before pics...

A nice 7/8 + blade with almost null for hone wear and a tiny small bevel that isn't honed into 27 different levels

-

The Following 9 Users Say Thank You to gssixgun For This Useful Post:

AcquaDiParmesan (01-26-2017), Blackstangal (03-07-2010), Geezer (07-29-2010), HNSB (03-05-2010), MikeT (08-01-2016), nipper (06-29-2012), ShavedZombie (06-12-2010), tictac (07-03-2012), tinkersd (02-26-2012)

-

03-04-2010, 08:14 AM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,210

- Blog Entries

- 1

Thanked: 13250 The New Buffer Bench !!!

The New Buffer Bench !!!

I built this around one of the support beams in the shop, it is 6'x8' 3/4" particle board framed on a 2"x6" and supported by 4"x4" posts..I can walk across it so it is pretty solid... I still haven't had time to start the shelves that are going in underneath it

There are 6 Harbor Freight Buffers that turn at 3450 rpm I run them most of the time with 4" wheels for polishing metal,,, I normally polish from spine to edge but that is a personal preference some people go from toe to heel also some go both directions...

On the far end is the last HF Buffer set up for polishing scales, and a single wheel buffer that turns at 1725 rpm and that I use for the final polish on the blades..

BTW in the pic above, that doorway leads to the old entry way to the small 2nd house that I call my shop, it is fully enclosed out there and that is where I keep all the "dust makers" like the saws and sander... Only my Scroll Saw and Drill Press are in this end of the shop

Last edited by gssixgun; 03-04-2010 at 09:31 AM.

-

The Following 19 Users Say Thank You to gssixgun For This Useful Post:

Del1r1um (03-04-2010), HNSB (03-05-2010), JaimeCobos (02-12-2014), jc50 (02-09-2013), jmercer (08-31-2015), MikeT (08-01-2016), MuskieMan33 (02-12-2014), Mvcrash (09-16-2010), ne0nblakk (12-24-2013), nipper (06-29-2012), Purvis (04-20-2011), riooso (04-20-2011), ScottGoodman (03-07-2010), seanreum1 (10-27-2014), ShavedZombie (06-12-2010), str8fencer (04-20-2011), STRAIGHTRAZOR13 (03-04-2010), tictac (07-03-2012), Zephyr (04-08-2012)

-

03-04-2010, 08:20 AM #3

very curious, glen (always about your mystical little vulcan-forge out there in Ideeho)- but the images, "Attachments" dont seem to work?

-

03-04-2010, 08:38 AM #4

-

03-04-2010, 08:46 AM #5

-

03-04-2010, 08:55 AM #6At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,210

- Blog Entries

- 1

Thanked: 13250 The Greaseless Compounds

The Greaseless Compounds

I use the Fomax compounds and I start at 80 grit, how long you stay at 80 works pretty much the same as handsanding with wet-r-dry does.. You stay at the lower grit until you have clean steel, or as clean as you decide you can get...

I just progress on up through the grits until the 600, at that time I use the brake cleaner and make sure the blade is clean and dry.. Make sure if you are wiping the blade off that your rag is clean because Murphy's Razor law says that it will have a piece of something that will leave a scratch on your nice finish

-

The Following 8 Users Say Thank You to gssixgun For This Useful Post:

32t (01-12-2011), HNSB (03-05-2010), MikeT (08-01-2016), MuskieMan33 (02-12-2014), nipper (06-29-2012), Purvis (04-20-2011), ShavedZombie (06-12-2010), tictac (07-03-2012)

-

03-04-2010, 09:07 AM #7At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,210

- Blog Entries

- 1

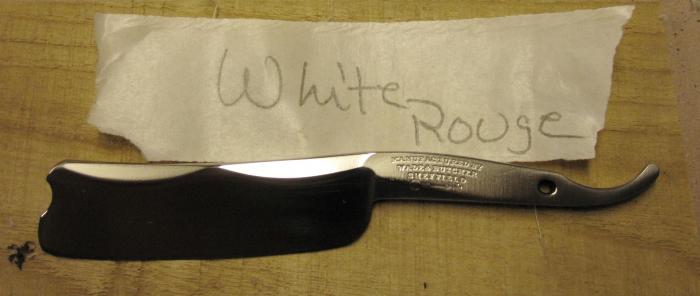

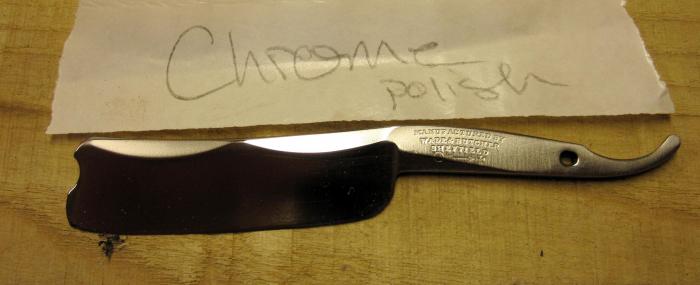

Thanked: 13250 The Polishing Compounds

The Polishing Compounds

These normally have different names depending on the brand you are using but pretty much start at some type of Emory and progress up in grit to some type of very fine Rouge..

I change my wheels during this stage when I get to the Rouges, I switch to a Soft buff from the Sewn Buffs that I used from the 80 grit all the way through... I first started using Sisal buffs in the lower grits (80 & 120) but switched to the Sewn buffs and liked the results better, but again that is just a personal preference...

My final polish is usually a mood thing I have lately started using the Turtle Wax compounds but honestly I have tried just about every polishing compound you can think of, again whatever you think looks best...

I have lately started using the Turtle Wax compounds but honestly I have tried just about every polishing compound you can think of, again whatever you think looks best...

This stage is where the Brake Cleaner is indispensable, you want to make sure the steel is totally clean from the last compound, before moving to the next one... The spray Brake Cleaner cuts it right off there, no muss, no fuss, try it out..

Emory Compound

Stainless Steel Compound

White Rouge

Chrome Compound

Last edited by gssixgun; 03-04-2010 at 09:16 AM.

-

The Following 10 Users Say Thank You to gssixgun For This Useful Post:

CaptStatic (02-25-2012), HNSB (03-05-2010), mauledbyakitten (02-19-2012), MikeT (08-01-2016), MuskieMan33 (02-12-2014), nipper (06-29-2012), Purvis (04-20-2011), ShavedZombie (06-12-2010), str8fencer (04-20-2011), tictac (07-03-2012)

-

03-04-2010, 09:21 AM #8At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,210

- Blog Entries

- 1

Thanked: 13250 The completed W&B "American" in Melted Bronze Acrylic

The completed W&B "American" in Melted Bronze Acrylic

You didn't think I was going to leave ya hanging did ya????

Here are some pics of the finished razor, again the camera just can't seem to catch the sparkle of the real scales...

I used a Black acrylic wedge and Tri-Metal stacked washers with Nickel Silver pins...

Last edited by gssixgun; 03-04-2010 at 09:24 AM.

-

The Following 23 Users Say Thank You to gssixgun For This Useful Post:

BigBubba (03-04-2010), CaptStatic (02-25-2012), carrolljc (06-02-2014), CraigC (01-14-2013), DMD (05-24-2010), HNSB (03-05-2010), jc50 (02-09-2013), JOB15 (06-21-2018), luckypip (05-10-2019), matt321 (03-04-2010), mauledbyakitten (02-19-2012), mglindo (06-01-2014), Michael70 (08-03-2016), MikeB52 (02-05-2017), MikeT (08-01-2016), MuskieMan33 (02-12-2014), nipper (06-29-2012), red96ta (03-06-2010), ShavedZombie (06-12-2010), str8fencer (04-20-2011), STRAIGHTRAZOR13 (03-04-2010), tictac (07-03-2012), wqueiroz (02-20-2011)

-

03-04-2010, 09:24 AM #9

-

The Following User Says Thank You to JMS For This Useful Post:

gssixgun (03-04-2010)

-

03-04-2010, 09:29 AM #10

Nice work Glen!

Your workshop looks amazing! One of these days I'm going to have a workshop like that. The flat is just a little too small for a shop, and I dont think SWMBO would appreciate me bolting a load of buffers onto the dining room table...!

-

The Following User Says Thank You to Stubear For This Useful Post:

gssixgun (03-04-2010)

36Likes

36Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote