Results 21 to 30 of 55

Thread: Is anyone using a Planer ???

-

03-13-2012, 01:40 AM #21At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,159

- Blog Entries

- 1

Thanked: 13249

Thanks gents, for all the input, it looks as though my initial info was correct that a planer is probably not going to work for what I need it to do, I am going to take a look at the surface sander that Theseus linked when I go to Spokane next and actually bring two scale blanks with me to see if the Woodcraft store there will let me demo it out

It may or may not work any easier then my belt sander and Jig that I use now, If I take the time to use the Jig I have, life is good, but often times I freehand things and have lost about enough fingertip skin to the belts...

So I started looking for an accurate, easy, fingersafe new way to bring the blanks into line, might take some time to improve on the system I already have for the $$$ to make sense...

-

03-13-2012, 01:43 AM #22Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

I forgot to say why you should buy 14 inches blank that way after you rip the piece if your cut is not completely acurate you have a piece that 14 inch long you cut in half, and your scales blank are identical!!

-

03-13-2012, 02:04 AM #23At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,159

- Blog Entries

- 1

Thanked: 13249

MMMM been there have that done that...

I look for grain accuracy ie: 2x2x7 blocks, two rips leave two Bookend grain pieces for the blanks. also the thinner the Kerf of the blade the more perfect this mirror actually is with wood or acrylic blocks... This is why I really like the Bandsaw for the rips but the Bandsaw just is not accurate/smooth enough for the 1/8 inch blanks they have to be sanded down too be a perfect matching size

Cutting a 14x2 x 1/8 will give the same piece but no bookends, access to 3x24x1/8 is as simple as contacting Bellforest but it doesn't give me Bookends yes I admit to being picky but it is the little things that count...

yes I admit to being picky but it is the little things that count...

Last edited by gssixgun; 03-13-2012 at 02:08 AM.

-

03-13-2012, 02:09 AM #24Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

03-13-2012, 02:28 AM #25At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,159

- Blog Entries

- 1

Thanked: 13249

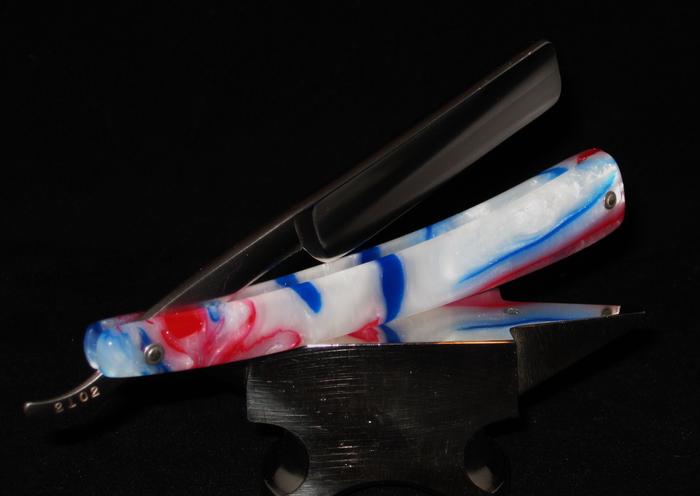

Look at the colors, see how they match from side to side, I try to get them as close as possible, the differences on these are caused by the kerf of the tablesaw blade, otherwise this would be easy ..

I have to have two blanks 1.5x6x 1/8 or as close to it as possible, I can already do this, I have little to no waste, now I want to do it easier and with less pain to my fingers...Last edited by gssixgun; 03-13-2012 at 02:31 AM.

-

03-13-2012, 02:33 AM #26Senior Member

- Join Date

- Sep 2011

- Posts

- 224

Thanked: 20

Check this out:

G0459 12" Baby Drum Sander

-

The Following User Says Thank You to Joegags For This Useful Post:

gssixgun (03-13-2012)

-

03-13-2012, 02:39 AM #27Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

I understand and just explained my method to you for bookends, every two pieces you cut will yield 2 set of bookends scales.

Only problem is blade kerf, if you want quality there will be waste.

And that sander at woodcraft i really dont think it will do the trick, you have a better chance to get a good PHIG from them, then that drum sander to work with a 7 inches X 1/8 piece of wood!

-

03-13-2012, 02:43 AM #28At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,159

- Blog Entries

- 1

Thanked: 13249

Yep Joe I think that is the right type of machine, although the Minimum size of stock is better on the Jet that theseus linked to

I will look at them in person and see what is what

-

03-13-2012, 03:32 AM #29

Not wanting to be pedantic or anything but the correct term for splitting a piece for near identical grain pattern is bookmatching, and the key word here is near, because the kerf of any blade used will remove material therefore the two halves will never match identically, even splitting the timber which is another time honoured way of doing it still results in the material having to be planed, so whatever way one looks at it there will be material lost.

The differences are glaringly obvious when used in this application,

However with razor scales there is a degree of separation ie the gap for the blade so the difference will be less noticeable, in my experience of 25 odd years of guitar making by far and away the easiest and most accurate method of reducing material to a thickness for scales would be to use a small bandsaw with a thin blade to cut the timber and this STEWMAC.COM : Luthiers Friend Sanding Station or something similar to fine tune the thickness, with a bit of inventiveness a home brew version is not difficult to make, and the thickness can be accurately dialled in, its simple and repeatable and works on small lengths.

-

03-13-2012, 03:36 AM #30Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

That sanding Jig is a fantasik lookin thing,next tool on my list,thanks for posting it

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote