Results 11 to 20 of 50

-

06-01-2012, 08:37 PM #11Who's that guy think he is...

- Join Date

- Jun 2011

- Location

- The North Coast, Ohio

- Posts

- 2,455

Thanked: 146

back to the matter at hand, did you use a brake bleeder type vacuum pump?

-

06-01-2012, 08:45 PM #12At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,037

- Blog Entries

- 1

Thanked: 13249

-

06-01-2012, 08:56 PM #13

This is a very interesting project! I'm looking forward to see how it goes!

-

06-01-2012, 10:17 PM #14At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,037

- Blog Entries

- 1

Thanked: 13249 PICS as demanded LOL

PICS as demanded LOL

Jar = Valsic 1 1/2 quart $3.42 with Pickels

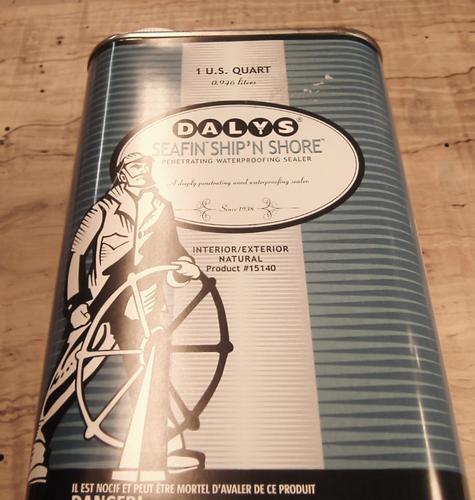

Daly's = $16 per Qt x 2

Fittings & Washers = $8.69

Silicon Sealer = $4.49

Pump Kit $24.99

Feeling of success when it worked, and didn't implode like so many people warned about = Priceless

Tricks I have learned already,

Slowly bring the pressure down about 5 in/hg at a time let the foam up occur and then bring it down again

After 1 hr release the pressure, and then let the wood sink lower, and drop the pressure again

I have it holding at 25 in/hg and it has held there today for over 4 hours so far

Do NOT let the sealer touch the fitting inside the jar it will wreck your pump if it gets sucked in

You can create a double "Boiler" type set up and keep things really safe if you can get the right size glassware ie: a smaller jar of finish inside a larger jar that holds the Vacuum

The first batch of Burls

Last edited by gssixgun; 06-02-2012 at 12:22 AM.

-

-

06-01-2012, 10:24 PM #15Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Thats a great thing,can you wgt a pce before and after? might be interesting.

Do you see any evidence of water in the mix? or was the wood dry beforehand.

This is great stuff,thanks.

-

06-01-2012, 10:25 PM #16Easily distracted by sharp objects

- Join Date

- Apr 2011

- Location

- Tempe, Arizona, United States

- Posts

- 824

Thanked: 94

that wood looks amazing Glen!

-

06-01-2012, 10:26 PM #17..mama I know we broke the rules...

- Join Date

- Feb 2010

- Location

- Toronto, Ontario, Canada

- Posts

- 2,895

- Blog Entries

- 8

Thanked: 993

Bottom line: This is freakin' cool.

-

06-01-2012, 10:28 PM #18

No one best be complaining for a lack of photography here, Glen.

Awesome set-up and nice results!

-

06-01-2012, 10:32 PM #19At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,037

- Blog Entries

- 1

Thanked: 13249

So far the hardest parts were finding the right jar

Finding and adapting the fittings

and Resisting the urge to keep testing the wood every couple of hours to see how it is drying

BTW This is NOT my idea, I just simply adapted it specifically for my usage

-

06-02-2012, 12:07 AM #20'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

Hi Glen,

Once upon a time I took a class in electron microscopy, and we embedded our specimens in a resin that set when baked. Don't remember the temperature, but I don't think it would harm wood. We kept a range of resin solutions--10% resin, 90% solvent (acetone, I think, or absolutely dry ethanol), then 20% resin, and so on. It was really time consuming, time in each bath before moving on, but we got subcellular impregnation.

I have no idea what the stuff cost or where you get it, but it was tough and transparent when it set. There's got to be a microscopist among us. Anyone? Anyone?

Where did you get your pump and vacuum gage? With a little extra hassle you can put another container in series to catch any fluid and protect your pump.

Cool setup.Last edited by roughkype; 06-02-2012 at 12:10 AM.

-

The Following User Says Thank You to roughkype For This Useful Post:

gssixgun (06-02-2012)

29Likes

29Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote