Results 21 to 30 of 59

-

01-07-2013, 02:03 AM #21

I made a flat bit to make the female part from a ¼" drill bit i ground with a 1/16th diameter teat at the start to assure centering. Like a spade bit honked out with a Dremel on low speed. I used a lathe to drill it in but a properly used drill motor and vise would work as well if used carefully' not much depth to cause a lot of heat.

I used a ¼" hard steel dowel pin that I ground about the first 1/8th" of length to a 1/16th inch diameter in a drill motor with a Dremel and cut off wheels. I use with the punch and die set to make washers centered. I first drill 1/16th" diameter holes a bit apart in the shim stock and then use the 1/16th" tip of the dowel pin to center the washers and then hit it to punch the washers..

-

The Following User Says Thank You to Geezer For This Useful Post:

celticcrusader (10-08-2013)

-

01-07-2013, 02:18 AM #22At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,194

- Blog Entries

- 1

Thanked: 13250

There are a couple of threads on here from way back first with Vlad and then with Philadelph on how they made them, some pretty good reading if you search the archives... You might find some really good stuff hidden in those threads

-

01-07-2013, 02:24 AM #23Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Geezer,your a machinist,think forming cutters maybe.

-

01-07-2013, 02:49 AM #24

-

01-07-2013, 02:56 AM #25

-

01-07-2013, 03:04 AM #26

Another post where I didn't make my thoughts clear.

I was not questioning the use of steel washers as backing for brass. But the substitution of aluminium in place of the steel. Nickel silver was also mentioned as an easily worked alternative. From the charts nickel silver would be less reactive with brass than steel and therefore maybe a better alternative.

A good example of incompatible materials used in razors would be cellulose and steel causing cell rot.

-

01-07-2013, 03:09 AM #27

It's something to think about for sure, but usually there needs to be a solution around the 2 metal parts for serious corrosion to take place. So unless someone is soaking the razor in water I think it should be fine. I would like to get steel sheet just to be the most authentic though.

-

01-07-2013, 03:35 AM #28

Aliuminum was used in some razors when it was as expensive as silver or gold due to the refining methods then in use. It does not hold up well to common bases..like soap.

German/nickle silver has long been used in razors and pocket knives as backing for mother of pearl, leather, shagreen and galuchat and also was/is carved for wedge and pivot blocks for years since first invented (about 1770) and other than a greenish patina which scrubs off easily it worked and works well.

Some quality DE and SE razors were, and maybe are still are, being made of it. Drafting instruments were commonly made of brass and nickle silver, with steel pins and furniture such as setting thumbscrews and needles as the pivots into paper.

Nickel silver - Wikipedia, the free encyclopedia

Too long winded but I needed to to describe the material as it is used. It may be considered as another type of brass.

~Richard

-

03-25-2013, 03:53 PM #29Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I don't think so. For galvanic corrosion to happen you need one more thing - the parts to be immersed in an electrolyte. In this case, water. The phenomenon only occurs while in the presence of the electrolyte - if it is not there, there is no way for potential to flow, so corrosion does not take place. In theory there would only be a small window of opportunity for this to happen. In places where it is a problem - mixed metal plumbed systems, etc, these are in the presence of the electrolyte all the time, and corrosion still takes a long time to happen.

With regard to the old over-sized holes in razor tangs, Richard is correct - the old ones were struck with a spike. According to how old/worn the spike was, the squarer or more oblong the hole. Sometimes you make out a depression on one side and a 'bloom' on the other - much the same as with deeply impressed makers marks, where the metal deforms. I have had to grind-off more than a few of these minor discepancies to get blades to close centrally.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

Geezer (03-26-2013)

-

10-08-2013, 02:53 PM #30

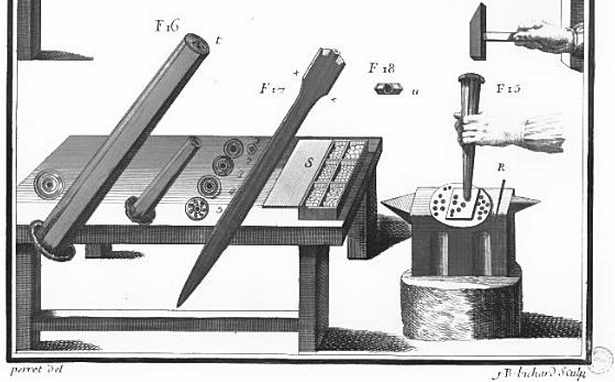

I know this is an old thread, but we just found this image and I wanted to compile it here. This is from Perret's book from 1771 (L'Art du Coutelier) and shows the method at the time for making these - stamping a reverse single die into the receiver of a sheet of lead (which I saw in a video somewhat recently but didn't click until just now).

-

113Likes

113Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote