Results 81 to 90 of 90

Thread: Hoping to build a grinder.

-

02-09-2016, 07:37 PM #81Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

OK, I picked out a spring . Looks like it should work fine for me . Raymond Die Spring, Medium Duty, 1x3 In 104512 | Zoro.com

-

02-09-2016, 08:01 PM #82

-

02-09-2016, 08:02 PM #83Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

Nice .I guess mount it on a bolt ? you can tell I am a little anxious. The next steps are bring all the steel to my friends for welding, making sure alignment is good for all wheels. mount the motor , decide on if I should build a free standing table for it , wire a 220 plug in my house "friend is going to do that also" , then fire it up. Maybe in the meantime I could rough out a razor blank out of some 01 steel I have . of course I will post pics as I get closer.

Last edited by drmccubx; 02-09-2016 at 09:48 PM.

-

02-13-2016, 12:53 PM #84Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

ok, i got every part i need , maybe i post a pic later of everything. vfd and motor still at my friends . uprights i went overkill 3/4 inch thick steel, 5 inch wide 7 inch long. i wanted the tooling arm to not hit the motor in the rear. I got the spring in the mail. its tiny but strong . it should work. it fits on a 1/2 inch thick threaded rod nicely. i am not sure if the spring will need to be mounted on something though. to make it higher . we will see as i assemble. a few critical pieces to weld. Weld uprights to steel plate. Weld tracking assembly left and right pieces to tension arm . Thats really it . then wet sand the whole rig and paint it . and oh, i need to buy some wire to wire the 220 plug for the house , from box to bench.

-

02-20-2016, 11:45 PM #85Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

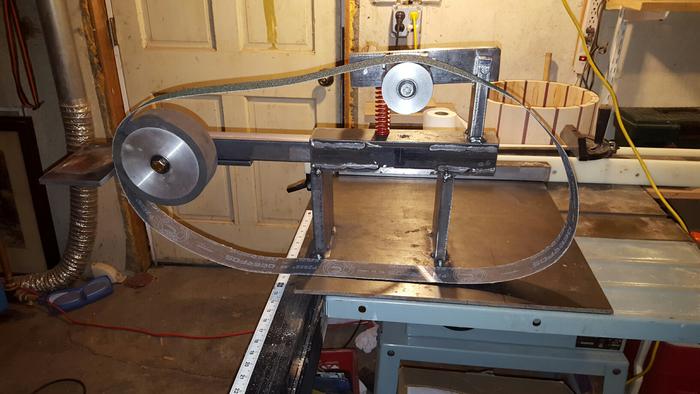

so here it is so far, just tack welded . It lines up well . Plenty of room for the motor . VFD will mount underneath on the stand that holds the grinder. I still need to figure out what bolts to use for the contact wheel and the tracking wheel. But , hey , its getting there.

-

02-23-2016, 12:28 PM #86Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

Well I am concerned about my spring it is so hard to press down .I think it would take 100 lbs of forse to move it 1/2 inch. Should I be concerned?

-

02-23-2016, 02:28 PM #87

This 'feature' came up with my grinder at the Texas meet. The person who brought it up was used to changing belts by depressing the arm without loosening the tool bar, which would be very difficult with a stiff spring. I had never thought of doing it that way.

I always loosen the tool bar to change belts. I put the belt in place, lean on the tensioning arm with my right fore arm, slide the bar out and tighten the set screw with my left. Harder to explain than to do.

I always loosen the tool bar to change belts. I put the belt in place, lean on the tensioning arm with my right fore arm, slide the bar out and tighten the set screw with my left. Harder to explain than to do.

When the grinder is in use the throw on the spring is irrelevant as there is little to zero movement in the tensioning arm. YMMV, but if I were building my grinder again I would use the same stiff spring.

-

03-07-2016, 04:31 PM #88Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

So , I have an issue, or maybe not ? you decide. the tooling arm is not "perfectly" straight . thus the contact wheel is slightly off. and I mean slightly. I think once complete the belt will be able to be adjusted by the tracking wheel and it should not make a difference or am I mistaken ? Or,,, and I mean ,,, Or,,, should I re do the tooling arm and make a new tooling arm holder . Can it be a hair off and not have issues with operation ?

-

03-07-2016, 05:45 PM #89Senior Member

- Join Date

- Jul 2015

- Posts

- 143

Thanked: 9

Yes it can... it is not ideal, you aim to get the two largest diameter wheels tracking the closest, but this is on knife sized contact and drive wheels, not too sure about small ones.

I would just try it, and shim it with soacers or washers...

-

03-09-2016, 08:02 PM #90aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

A long straight edge like a level will show you where to bring wheels out with spacers. Randy Tuttle showed me that trick.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

59Likes

59Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote