Results 41 to 50 of 90

Thread: Hoping to build a grinder.

-

04-20-2015, 06:27 AM #41

measure the shaft across the diameter only not where the key way is

so 90 degrees to your pictureSaved,

to shave another day.

-

04-20-2015, 08:14 AM #42

There are many different sizes. If you're going to make knives, I suggest you buy a pair of calipers.

they're cheap, and you will be able to tell exactly how thick or wide a piece of metal is.

Sometimes the difference in axle sizes is minute, and with a simple ruler, you're not going to be able to tell.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

spazola (04-20-2015)

-

04-20-2015, 05:38 PM #43Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

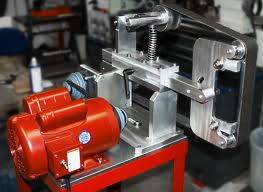

I have a caliper. it measures the shaft .875 . 7/8ths of an inch. so ,according to the KMG plans I go buy I need to buy a shaft that is 7/8ths inches wide. but on there parts list , it looks like he purchased a 2 foot long shaft. I don't think there is a need for such a long shaft. so the way I figure is once side of shaft has drive wheel, then through the pillow block bearings. then a pully on the other end. the pully has a small belt going to the pully on the motor. I suppose I could just line up the motor behind and run the drive wheel right on the motor ? but that would elongate the entire unit.

you will see in the attached pic what I am talking about . I could 1...either use the pully system to drive the wheel. ? Or is there a way to just extend the shaft of the motor? buy another shaft and couple them together ? suggestions ? this is all new to me . thanks, David

-

04-20-2015, 05:51 PM #44

The drive wheels for my grinders are mounted directly on the motor.

The motors are powered by a VFD so pulleys are not necessary.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

04-20-2015, 06:10 PM #45Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

so , do you mean like the attached. just mount the motor behind he structure ? I guess since the kmg plans I am looking at don't have it that way but seems easy enough ?

Also, I am getting ready to purchase the tooling arm . how long does it need to be ? if I have 2 , is 18 inches each enough. I am going for a round contact wheel and a flat platen , so it would be nice to have a tooling arm for both .Last edited by drmccubx; 04-21-2015 at 12:44 AM.

-

04-21-2015, 03:35 PM #46aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

If you have a VFD, mount the motor just like your picture in post #45. If you don't have a VFD, mount the motor like post #43. You need to be able to control you speed.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

04-21-2015, 03:36 PM #47Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

Yes I have a vfd. Thanks

-

04-21-2015, 03:53 PM #48

This depends on the size and placement of the drive and tracking wheels, in relation to the receiver tube, and the size of your smallest contact wheel. I use a 2" drive wheel and often a 2" contact wheel. The 1-1/4" tool arm was sold by the foot. It appeared that I could get by with 20" so I ordered 2 feet. I saw no reason to cut 4" off so I left it at 24" now I'm glad it's a little long because there is better support as well as the possibility of shortening it if I ever needed to change any of the holes in the working end.

-

04-21-2015, 09:38 PM #49Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

-

04-21-2015, 11:13 PM #50Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

yup . that's it . I will just mount the drive wheel to the motor and place the motor where it needs to be to line up with the other wheels when the time comes.

59Likes

59Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote