Results 71 to 80 of 90

Thread: Hoping to build a grinder.

-

02-05-2016, 07:07 PM #71"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Die Springs | MSCDirect.com

These are what I replace stock springs with on my Baders.

-

02-06-2016, 12:11 PM #72Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

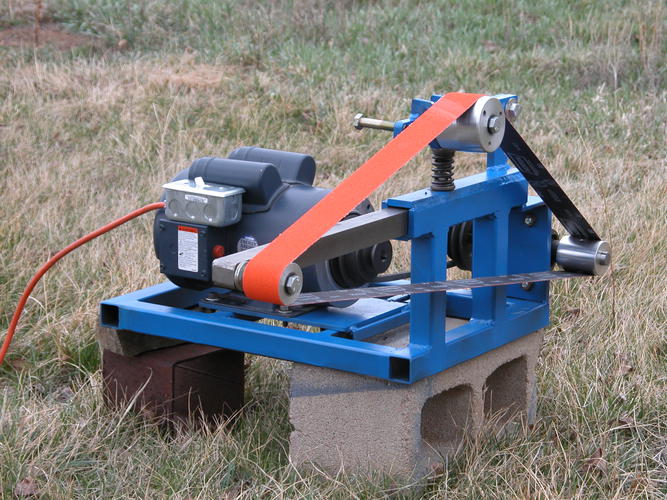

ok, so here is a sample of progress on my grinder , years after starting. one pic of tooling arm, one of tracking assembly, one of work rest , one of flat platen . All are "in progress" . Tooling arm has to be welded to uprights , platen needs more holes drilled and platen welded on, tracking assembly needs to be welded to tension support . Today i go and get Bolts to hold on the wheels and other parts .

-

The Following User Says Thank You to drmccubx For This Useful Post:

MikeB52 (02-06-2016)

-

02-06-2016, 08:26 PM #73Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207 "Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

02-06-2016, 10:48 PM #74Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

yeah, running up and down stairs to work a little here and there makes putting shoes on troublesome . But , alas , i should wear shoes.

So, i got some bolts , lock washers , lock nuts . Work rest looks great . Now waiting on steel from local welder for the uprights. Though i do have some 3/8th's inch thick steel i could use . I asked the welder for 3/4 inch thick . Would it make a difference ? Whats everyones take . 3/8ths or 3/4 for uprights to hold tooling arm ? Very few steps to go . Oh , another question . Do people use threaded rod for the wheel axles ? or get long bolts and washers ? Hopefully next week it gets welded up

So, i got some bolts , lock washers , lock nuts . Work rest looks great . Now waiting on steel from local welder for the uprights. Though i do have some 3/8th's inch thick steel i could use . I asked the welder for 3/4 inch thick . Would it make a difference ? Whats everyones take . 3/8ths or 3/4 for uprights to hold tooling arm ? Very few steps to go . Oh , another question . Do people use threaded rod for the wheel axles ? or get long bolts and washers ? Hopefully next week it gets welded up

-

02-07-2016, 01:13 AM #75Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

so here is the tool rest done. You get the idea

so here is the tool rest done. You get the idea

-

02-07-2016, 01:15 AM #76Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

here is the vfd and motor. It's getting there

here is the vfd and motor. It's getting there

-

02-07-2016, 01:16 AM #77Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

slots made for adjusting platen.

slots made for adjusting platen.

-

02-08-2016, 08:17 PM #78Senior Member

- Join Date

- Dec 2013

- Posts

- 152

Thanked: 5

So I guess my question about a spring is what length to get ? Thanks mike for the suggestion. I just don't know if the one you suggest will do . its 3 inch length is short , no ? for a KMG clone that is . I just don't want to guy and have to return . I was told it should compress 1 inch per 30lbs ?

-

02-09-2016, 02:05 AM #79

looking good & progressing well mate

also good to see someone who wears the same shed safety shoes as me LOLSaved,

to shave another day.

-

02-09-2016, 03:45 PM #80

I use a valve spring along with the spring seats on a KMG clone. The spring is much stiffer than 30lbs per inch. I don't think that the rate is very important, though it seems to me that a stiffer spring makes the design easier because the length does not change very much over a range of tensions. I would guess that I use the grinder with about 30-50lbs of tension in the spring.

59Likes

59Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote