Results 71 to 80 of 143

Thread: An experiment in steel

-

01-11-2010, 09:11 PM #71

I'm no electrician but was wandering if hooking up a dimmer switch into the line might be able to control the wheel speed, I know these grinders can use a no volt switch so they might turn off below a threshold voltage??

I admire the fact the Mike has just had a go and got this far, more guy's should. It don't matter how it turns out it's all learning. Time is a factor but it beats tv (yawn).

-

01-11-2010, 10:06 PM #72

I'm sure the time involved would be reduced significantly with better equipment, and it would probably be cleaner work... But so far so good.

I'm learning by leaps and bounds...

I need to find an affordable belt sander that has a good selection of belts/grits...

I remember some threads about them, so when time allows I'm going to have some serious reading to do.

I may go to yard sales and try to find a used treadmill...

-

01-11-2010, 11:12 PM #73

To my limited knowledge, it isn't really a good idea for bigger motors like you'd find on grinders or buffers. Rotory tools like a dremel, maybe. The reason I say this is because I was discussing doing this with my father who does electrical engineering and he said it wasn't something he'd consider... I don't have any other info than that.

-

The Following User Says Thank You to Del1r1um For This Useful Post:

Deckard (01-12-2010)

-

01-12-2010, 03:10 PM #74aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Excellent read. Thank you for sharing.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

01-12-2010, 04:25 PM #75"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

The main problems are that you lose torque and it eventually becomes more wear and tear on the motor. It'd work if you only did things like this once in a while and weren't stressing the system.

A VFD would be the best solution. Motors are a lot less expensive and you can trick a 3 phase motor into thinking it's getting real 3 phase power and still have the variable speed off a 220 volt single phase line.

The next best solution is what ChrisL is looking for, a DC motor and variable controller. Recycling those is perfect for blades in this size range. You'll lose some of the torque, especially at slow speeds, but you won't burn up motors and electrical stuff as easily.

Keep a water tub handy and dip often. Finishing work like this is best done bare handed. If your fingers are getting hot, it's time to cool the blade. Even then, be careful, steel can feel hot from some induced friction but it still hasn't achieved its maximum temperature due to a lag in heat distribution. You might think you got off the belt/abrasive in time, but the heat in a thicker section might not be too bad there, but as the heat distributes through the thinner sections, it turns out to be too much heat.

Good thread Mike, keep it working.“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Deckard (01-12-2010)

-

01-12-2010, 04:59 PM #76

-

01-12-2010, 10:33 PM #77

I knew this would happen, where can I get a VDF and is there a typical type for these purposes. I have a general idea what they do, otherwise I don't know what VDF's are or how to hook them up.

Can anyone point me in the right direction as I am new to this.

Thanks

Deckard

-

01-12-2010, 11:18 PM #78"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Variable Frequency Drive

Here's a good place to start: Variable Frequency Drives Co - VFD & Drive on Sale!

But, I have an electric motor shop in my town so that's where I buy mine. He sets up the unit, makes sure it all works, bench tested etc. There are some calculations to set up at the outset.

But if I take things apart once that's done it's just like wiring anything else, hot to hot, ground to ground, simple screwdriver work. It's worth it to pay him a few dollars more and since I've been buying from him for years, they are getting cheaper. Plus I have someone to go to when things don't work or I have questions about what I think I want to do.“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Deckard (01-13-2010)

-

01-12-2010, 11:41 PM #79Senior Member

- Join Date

- Apr 2007

- Location

- St. Paul, MN, USA

- Posts

- 2,401

Thanked: 335

-

01-13-2010, 09:24 AM #80

haven't looked that far, I need to save a little bit of $$ first

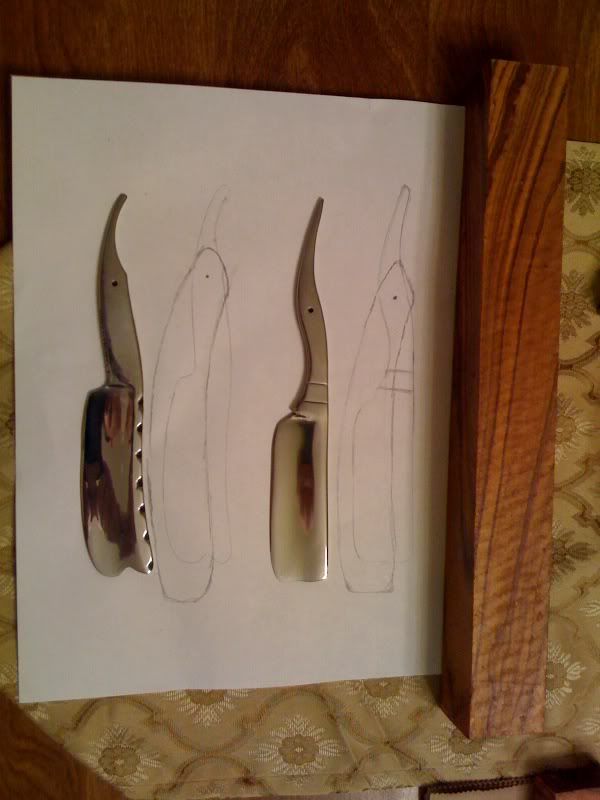

Latest update:

profiled the second razor down a bit, it will be a near wedge

sanded on flap wheels ( 80 & 120 grit). Lots of hand sanding, to 300 grit and a bit more elbow grease... It needs some serious buffing still, and it is not mirror finished, but not bad for a starter...

I've drawn up my scale design, and sected a nice piece of olive for them...

More pictures to follow...

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote