Results 61 to 70 of 173

-

01-12-2010, 05:14 AM #61

Yeah, when I first talked about moving the notch back I actually had your blades in mind, I have always noticed the little bump before the notch...

This was a stroke of pure luck, but I tried out the blank on cardboard, and it actually works for the way I hold my razors. Now, the notch isn't traditional, but see how it works with my grip (again, this was an accident that I'll be keeping in the design because it really works and I like the look)

I grip the razor pretty far back, and I only use three fingers to grip

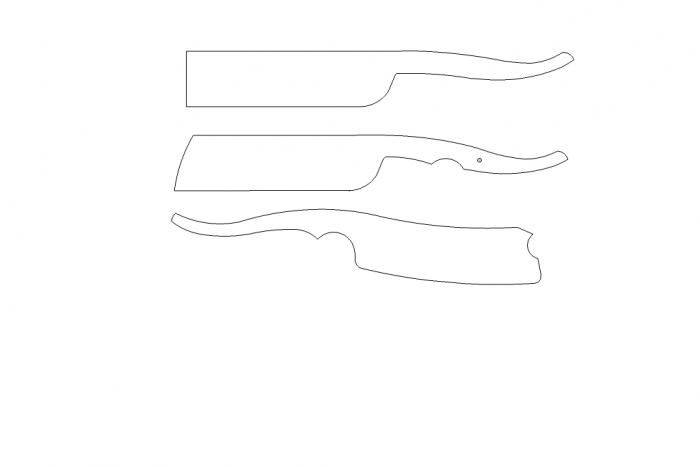

Here are the designs and the cardboard mockups

and here is how they work with my grip....

So, after trying out the blanks, these designs all work for me. And I did try them with mocked scales too... works great!

I made one design with a square profile and nothing fancy that could be a generic, it is 7/8 and modeled after my vintage blades... the tang is slightly longer, but I think it works. Anyway... I think we are getting pretty close to go time

BTW, seraphim... can you make your designs into 2d dxf files (lines only works best)?

Cheers

DaveLast edited by Del1r1um; 01-12-2010 at 05:30 AM.

-

The Following 2 Users Say Thank You to Del1r1um For This Useful Post:

FTG (01-13-2010), ScottGoodman (01-12-2010)

-

01-12-2010, 12:43 PM #62Member

- Join Date

- Sep 2008

- Posts

- 74

Thanked: 6

Again, I really like the notched razor the most...hope to see that blank...hopefully at least a 7/8...

-

01-12-2010, 01:42 PM #63aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

+1 on that one

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

01-13-2010, 02:11 AM #64

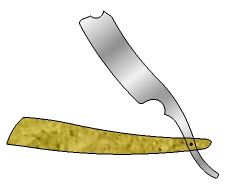

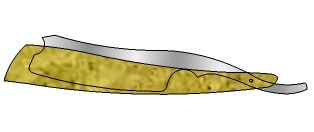

Man, I am having too much fun playing with this program... how do you guys think she looks in some scales? (the design is 7/8)

-

01-13-2010, 04:33 AM #65aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Pretty cool! I had grilled tenderloin for supper & have had my pudding...How much closer are we?

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

01-13-2010, 05:35 AM #66

we are very close!

I am actually a bit surprised by the interest level, I am getting pm's pretty regularly and there are lots of brave souls. I do want to propose something that I think is wise at this point (but we can talk about it via PM if you disagree). I think we should put the initial blank limit to 3 blanks per member. For one, we may have to because of the material limits and # of people involved. Another reason is that I think three blanks will give us plenty to keep busy with in order to see if this is anything that is really feasible to do from time to time, while also limiting each member's risk/investment. I'd be much more comfortable with people risking 15 bucks than 100 on an experiment (those are not the real costs mind you, just making a point). I'm most interested in giving people a way and an excuse give razor making a try with little risk.

I have material quotes and I am doing a test run in order to see how many blanks we can legitimately layout on the steel in order to make final quantity decisions and calculate direct costs. Right now the layout is really tight w/o hardly any waste at all and if that works we are in great shape. If people have specific designs they want, they will need to send me a file so I can lay it out as well.

Also, the list made earlier when I said final call may have to be final for the first run... but we will see once the layout test is done. For those of you on the list lets do this.. unless you specify a different design (and/or supply me with one) I'll assume you are ok with the smiling design I made and the more traditional spike point blank. If you want something specific send me a PM.

So as soon as I have designs in hand, and run the test I'll be able to talk about prices, but if the layout works as is, a rough estimate to buy the material and get it shipped to our shop would be about $10 per member and that would cover 3 blanks each (seems pretty low risk ), but that is assuming everything goes according to plan... the only other cost involved would be postage from me to you in a padded envelope or something which shouldn't run more than a couple bucks via usps. Now, don't hold my feet to the fire if it changes slightly... but I am not going to pass on any costs for running the machine, my time, package handling or anything like that (just what it costs to get it done)... I just want to have some fun and share the fun with you fellas.

), but that is assuming everything goes according to plan... the only other cost involved would be postage from me to you in a padded envelope or something which shouldn't run more than a couple bucks via usps. Now, don't hold my feet to the fire if it changes slightly... but I am not going to pass on any costs for running the machine, my time, package handling or anything like that (just what it costs to get it done)... I just want to have some fun and share the fun with you fellas.

Send me a PM if you want to chat, or hammer anything out

Dave

-

01-13-2010, 06:59 AM #67

I'm not on the list. That's fine. I just wanna watch for awhile. I also have no means of doing the grinding. I assume I could find someone willing to grind them. (Compensated of course)

I do some very modest scale work and would LOVE to eventually be able to find a way to have a set of matching blades (around 10 blades).

With all that in mind let me add fuel to the fire by stating that if things get off the ground well enough to do a round of blanks open to the public, I'll be the first on the waiting list.

Besides, SRP needs it's own razors...right?

-

01-13-2010, 08:25 AM #68

About the hardness...

I really would not be too worried about that. The razors I made were treated by Mike Blue to be 62 +-.5 HRC. That is already very difficult to hone, and more than hard enough to have good edge retention. Also, you can get very good and smooth edges on older sheffield blades which are somewhere between 57- 59 HRC. So while hardness is important, I really would not try and go any higher than 62.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

Deckard (01-13-2010)

-

01-13-2010, 12:39 PM #69Senior Member

- Join Date

- Dec 2006

- Location

- Mount Airy, North Carolina

- Posts

- 195

Thanked: 188 Polishing

Polishing

I would be willing to help out on polishing some blades

Ronnie

-

01-13-2010, 12:41 PM #70Senior Member

- Join Date

- Dec 2006

- Location

- Mount Airy, North Carolina

- Posts

- 195

Thanked: 188

17Likes

17Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote