Results 81 to 90 of 170

Thread: Brian's First Blade

-

12-05-2011, 02:18 PM #81

Update time!

I PM'ed Mr. Blue and inquired about the status of my razor. Got this back:

Woot woot! No warp! I'm a happy, relieved guy. Now, to figure out a scale material. No G-10. Wood? Black horn? I'm not sure. Any suggestions? Originally Posted by Mike Blue

Originally Posted by Mike Blue

-

12-05-2011, 10:39 PM #82

Congratulations Brian. I'm happy that it has all well with the HT. I got my first two back this week from HT with straight edges also, it's a great feeling after putting in so much work.

If you haven't worked with horn before, it can present problems that a synthetic material will not, that being said buffalo horn comes up great. Robsbits is a fleaBay seller that has some nice natural materials.

Carbon Fibre looks great too.

Stu

-

12-06-2011, 01:50 AM #83

I can't find any of Robsbits listings. I'm thinking about bone with a wooden or pewter wedge actually.

-

12-06-2011, 01:23 PM #84

Or maybe black with white swirled buffalo horn and a pewter wedge, because I can't seem to find any camel bone in the appropriate sizes?

-

12-06-2011, 02:42 PM #85

Helpful link to robsbits Ebay shop - I'm not affiliated, just watching some nice bone bits on there myself

Bone and Horn Flat Pieces, Guitar Bits n Bobs items in Pietra Dura Etcetera store on eBay!

-

12-06-2011, 03:12 PM #86

Thanks Paddy. I actually found the store after I posted that. I still can't find any bone the appropriate size, but I may have something up my sleeve. Pictures to come......

Still, if anyone knows where to find bone, let me know.

-

12-06-2011, 04:35 PM #87"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Go to a Pet Store. They will have boiled bone already cleaned up and ready to slice up on the bandsaw.

“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

12-06-2011, 11:54 PM #88

Weeeeelllllll.......this is what I was going to show you, but I doubt it will turn out. I couldn't get the stinking paper to stay stacked while I tightened the clamps. It kept sliding everywhere, and finally I just clamped it down and gave up.

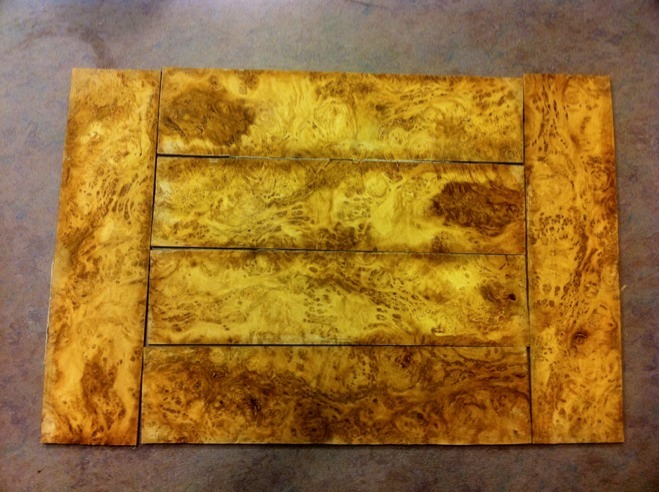

I have this as my backup though. I wasn't going to go with wood, but I picked up this piece and it just cried out to be used. $5 worth of labor later:

Front and back scales transferred to the choice pieces.

Hopefully I can get them rough cut tonight. They told me at the wood shop that sanding them up to 4000+ would make them really come alive. I'm not a big fan of plain wood, so I will have to find a nice stain color. Something in the red family of Minwax. Then either epoxy or CA finish. Ebony wedge I think, and brass pins. I have brass to make a lined wedge, but I will have to see how it all looks together.

-

12-07-2011, 02:59 AM #89Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Is the wood burled ash? If so, then the wood is fragile. I had that wood for scales and lined them with brass to make them stronger.

Last edited by randydance062449; 12-07-2011 at 03:24 AM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

12-07-2011, 04:30 AM #90

It is burled eucalyptus. I figured it would be very fragile as well, but it seems fairly strong so far. I don't see the need to line it right now, but I'm open to the idea if it seems like I need to later. The wood is very springy and not crack prone/falling apart like I've heard burls are.

Got the scales done and sanded to 2000. I guess I don't have 4000 or 8000 on hand like I thought I did. Still looking for a good stain. I'll probably have to wait until I get the blade back to see where I'm at on how everything looks together. PM'ed Brian Brown to ask about a pinless wedge he did back in October. I'm still thinking about doing that too. It really looked cool and it lets the burl be uninterrupted.

Thinking very hard about a CA finish. Very hard. Any ideas?

72Likes

72Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote