Results 1 to 10 of 56

Thread: Tim's 1st Blade

-

12-01-2011, 02:39 AM #1

Tim's 1st Blade

Tim's 1st Blade

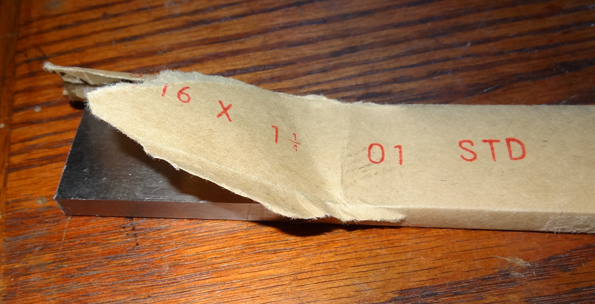

Well my steel arrived today! Ordered from Enco on Sunday and it arrived on Wed!

5/16 x 1 1/4 x 18 0-1

There's a Harbor Freight nearby so I grabbed some chisels from there just to get started ($10).

I have a full sized band saw but I don't know what kind of blade to get that would cut 5/16 0-1 steel. What do I need. I have a hack saw but Brian mentioned that he's had trouble cutting 0-1 with one. I'll lay out a design and see if I can make any headway with one.

-

12-01-2011, 02:56 AM #2

Is it a metal cutting bandsaw? on most wood cutting bandsaws the blade goes to fast to cut metal. If is a metal cutting saw I would buy a 14 TPI blade. I have cut blades out of O1 with a hack saw it is a work out but it can be done. (even by a big boy like me)

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

tumtatty (12-01-2011)

-

12-01-2011, 03:08 AM #3

D'oh..It's a wood cutting one. However I have a variable speed motor (the bandsaw is an attachment to the Shopsmith setup I have). Is it just speed that makes it into a "metal" cutting bandsaw?

Here's a Shopsmith setup for all you non-wood workers out there:

I use it to turn shaving brushes, cut out scales and I'm wondering if I can make a grinder out of it somehow....

-

12-01-2011, 04:27 AM #4

I have recently used a hacksaw for cutting O1. It is slow going but I got there in the end. I used a series of drilled holes for the tighter curves where the hacksaw couldn't quite get in.

O1 is harder than other steels I have used but not impossible. I don't own a bandsaw or any other power saws so I just used what I had. If you have the bucks, the metal bandsaw would sure speed things up.

Keep us posted with you progress pics.

-

The Following User Says Thank You to Str8Raz0r For This Useful Post:

tumtatty (12-01-2011)

-

12-01-2011, 04:41 AM #5Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Yes, the primary difference is speed. A metal cutting bandsaw moves very slowly.

This one has a cutting speed of 230 SFPM ( surface feet per minute) and works well.

FREE SHIPPING — Northern Industrial Portable Band Saw | Band Saws | Northern Tool + Equipment

I have used both a 14 TPI blade and a 24 TPI and prefer the 24 TPI but the 14 TPI is more commonly available.

Hope this helps,

Last edited by randydance062449; 12-01-2011 at 04:49 AM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following User Says Thank You to randydance062449 For This Useful Post:

tumtatty (12-01-2011)

-

12-01-2011, 05:38 PM #6

To be fair, I also said I am a wimp. I didn't [don't] have a vise, so it was hard to get a good bite with the saw. Now, I have seen a knife made by drilling then hammering a cold chisel between the holes and filing smooth. I might try that some time. I can wack stuff with a hammer pretty well. If it don't work, get a bigger hammer.

Seriously though, let us know how the shopsmith thing goes.

-

12-01-2011, 06:54 PM #7

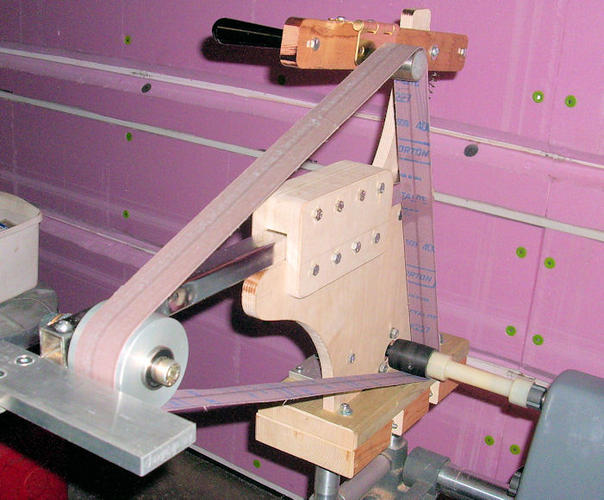

I found someone who made a belt grinder for his shopsmith. I think I'll spend my time making a blade for now, but this looks like a worthwhile project!

-

12-01-2011, 08:01 PM #8

Does this seem workable?

-

12-01-2011, 08:09 PM #9

-

12-01-2011, 08:15 PM #10

I like the design. Very interesting, though Zephyr makes a good point about being "behind" the spine. I look forward to seeing this project develop!

7Likes

7Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote