Results 21 to 30 of 215

Thread: Apache Black Gila

-

09-20-2015, 01:43 AM #21

Fairly rough...but he did offer to clean it up. I declined as I wanted it shipped immediately. I got it about halfway flat in 15 minutes with a dry XXC DMT. The feel in lapping is similar to a slate, but with a quality I can only describe as 'ceramic'...though that isn't an assessment of the structure, just the feel. It abrades easily enough with the diamond plate...but that's relative to my expectations, not other siltstone/sandstone based materials. It's VERY hard. That said...it's got nothing on quartzite/chalcedony when it comes to difficulty flattening lol.

-

09-20-2015, 01:52 AM #22Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,498

Thanked: 169

On my personal brutality scale, I waffle between carborundum and trans ark being the most miserable. Granted, you can use sic on a plate, but at some point you need to go to something else if you want it perfect.

-

09-20-2015, 01:59 AM #23Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,498

Thanked: 169

Mine always had two chips on the side at the bottom edge since I got it. This is how it chunks out:

-

The Following User Says Thank You to kcb5150 For This Useful Post:

bluesman7 (09-20-2015)

-

09-20-2015, 02:59 AM #24

Ugh! I had a whole post with a bunch of pictures typed up, and I closed the window!!

Those chips aren't like a slate would chip, and as a matter of fact, my entire commentary about the slate thing was completely inaccurate, and based on the feel and rough finish of the stone as I received it. The diamond cut it cleanly until the peaks were all knocked off. At that point, the entire thing just stalled. Soooo, I took it out to my shop to finish lapping it on a water cooled 40 grit Norton Blaze belt, as well as to cut off one of the corners that the cutter left a fractured piece on.

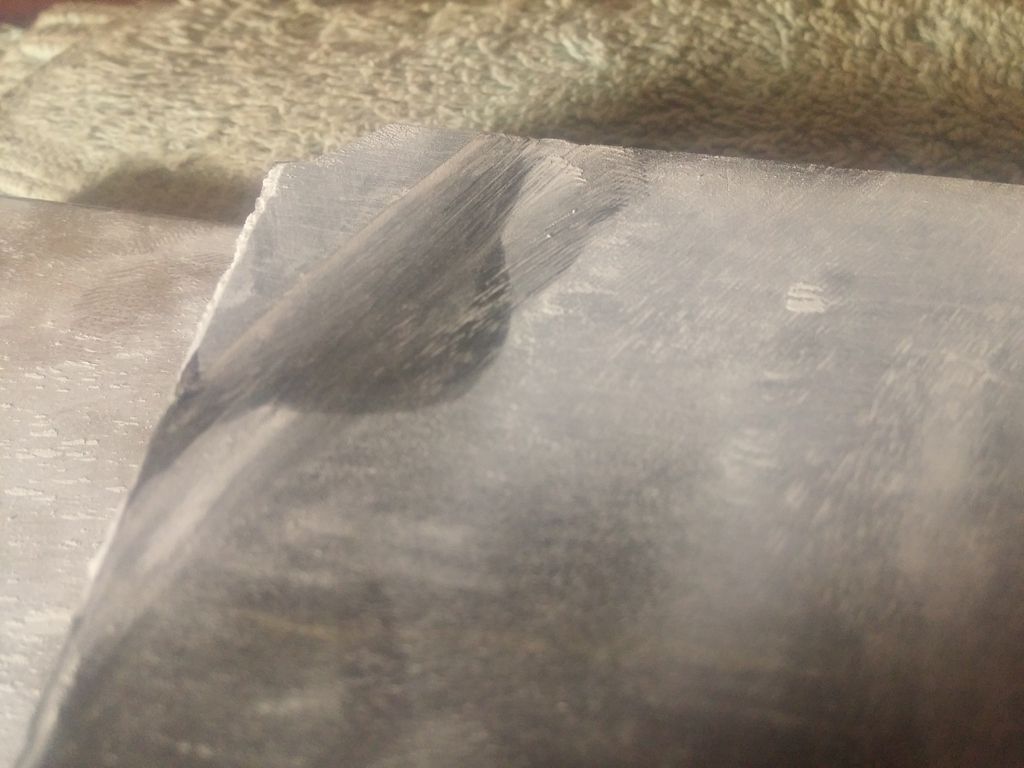

This is where the DMT stalled after about 20 minutes.

This is the 'chunk' that was left on the other side from the cutter. This material is very brittle.

This picture shows the end results of hitting it with a 20k rpm cutoff wheel. The material gets hot, and then fractures...just like quartzite does. The fractured pieces ARE semi translucent...which could make this material a cousin to the translucent Arkansas stones. A form of novaculite or chert. It certainly has more in common what a quartz based material than with a slate based material as I'd assumed earlier. Note the almost melted looking top? That's from the cutting wheel, not the stone.

These are the pieces that chipped out. As you can see, particularly on the middle one...they have translucent edges. Again, this supports the quartz based origins vs a slate base. It almost looks like a volcanic glass in a way...green, semi-opaque obsidian. Very strange. There are extinct volcano fields throughout the southwest and particularly in his area...so that would make sense as well.

After messing with it with the angle grinder, I took it to my water cooled, chilled platen 2x72 belt grinder, and loaded a brand new 40 grit Norton Blaze ceramic belt. This grinder moves at almost 5900 surface feet per minute. This picture is the end result of trying to cut the stone with that setup. If you look closely I knocked all of the corners off of the stone with the belt. To remove that much material took 45 seconds to a minute of grinding per side. It seems the ONLY effective way to cut this stone is with diamond.

So there we have it, my experiences this far. At the current level of refinement the stone feels amazing (obviously ignoring the chatter on the rough spots) when a junk razor is run over it. I can't wait to get it lapped out and see how it goes with real razors. I currently have two razors out of AISI W2 tool steel...both sitting at 63-64HRC, one Kikuboshi 24, and four Gold Dollars to mess around on with it.

Should be interesting, if nothing else!

-

09-20-2015, 03:37 AM #25Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,498

Thanked: 169

It's really interesting material. Very confusing, as it reminds me of a lot of things. It does feel like a surgical black to hone on but not exactly. I LOVE trans arks, so I have developed a huge soft spot for this thing being kind of similar but much much faster. Are you at a place where you can just refine by hand now?

-

09-20-2015, 03:55 AM #26

-

09-20-2015, 03:58 AM #27Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,498

Thanked: 169

I only do an ark dry until the very very end and that is only to keep any loaded up abrasive creating faint waves. Lapping dry is underrated

-

09-20-2015, 04:14 AM #28

That chunked corner of the stone after 20 minutes with the XXC DMT plate, and...

...after 20 more minutes.

-

09-20-2015, 04:17 AM #29Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,498

Thanked: 169

At least you have something nice at the end of the rainbow of horrors... It's what keeps me going when I am lapping.. I hate lapping rocks

-

09-20-2015, 04:37 AM #30

For sure!!

Out of curiosity...have you had any problem with the fissures in the stone?

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

. It's slow...but it's working. Dry is also better than wet for some reason.

. It's slow...but it's working. Dry is also better than wet for some reason.