Results 61 to 70 of 118

Thread: Nakayama Maruka

-

09-07-2015, 04:31 PM #61

Thanks, I never thought of it as impressive .

If I have an interest then I cant stop myself from acquiring the best stuff.

I have only had negative effects from generating DMT slurry.

One guy on this forum , I forget his name but he knows a lot (Mainaman), explained that you are using the surface structure of the stone with the slurry to get the desired effect. Therefore roughing up the surface can only have a negative effect on your blade.

I'm with him

Last edited by JOB15; 09-07-2015 at 04:37 PM.

-

09-07-2015, 04:54 PM #62Member

- Join Date

- Aug 2015

- Location

- texas

- Posts

- 35

Thanked: 3

-

The Following User Says Thank You to sstomcat For This Useful Post:

JOB15 (09-07-2015)

-

09-07-2015, 05:36 PM #63

I think the problem most folks have using diamond plates for slurry is that their plates are not worn out enough. I'm amazed that people use a 325 DMT to raise slurry. If you can still use the plate to lap stones with, it isn't worn down fine enough. I use a worn out 1200 Atoma and it does not produce visible scratches on the hone - I've gotten good results with it. If you can see scratches from the plate, then yes I think the "Arkansas effect", where the surface finish impacts the results, is in play. I've seen Alex's slurry plate in his videos and can conjecture it isn't making many scratches!

And there are workarounds. You can raise a diamond plate slurry, then break that slurry down with a tomo nagura to whatever degree pleases you. That said, a really well matched tomo nagura is best IMO.

When testing a new hone, I always like to use (worn out) diamond plate slurry because I want to understand the characteristics of the hone, not the nagura. Later on I'll match a tomo nagura to it if I can.

Cheers, Steve

-

09-07-2015, 05:48 PM #64

I wouldn't have the guts to use a diamond lapping plate on a Nakayama. I don't have a diamond hone so I can't be tempted

My feeling is that the diamonds must devour hone. Wouldn't Naguras be a much beter option? With a Nagura you can more or less choose the grit size of the slurry as well.

Plus ça change, plus c'est la même chose. Jean-Baptiste Alphonse Karr.

My feeling is that the diamonds must devour hone. Wouldn't Naguras be a much beter option? With a Nagura you can more or less choose the grit size of the slurry as well.

Plus ça change, plus c'est la même chose. Jean-Baptiste Alphonse Karr.

-

09-07-2015, 06:14 PM #65

I lap my Jnats with the 1200 plate, I also lap my 1k with the 1200 to try and wear it down a bit .

It always shocks me how the Tomo can take out those scratch marks.

So the Tomo removes layers of base stone adding to the slurry and smoothens it at the same time , its a win win.

Those soft JNS Tomos are quality by the way.Last edited by JOB15; 09-07-2015 at 06:18 PM.

-

09-07-2015, 06:36 PM #66

Kees,

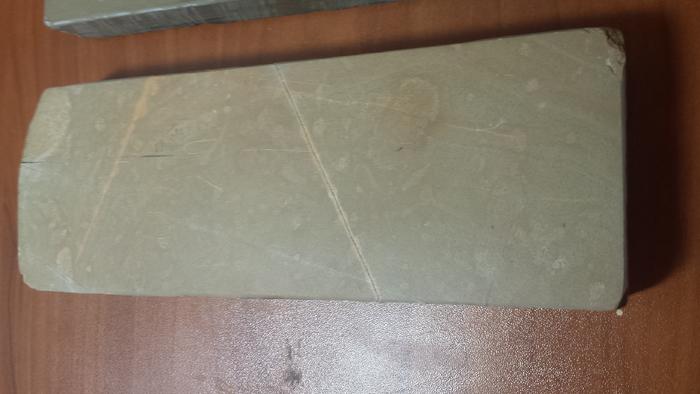

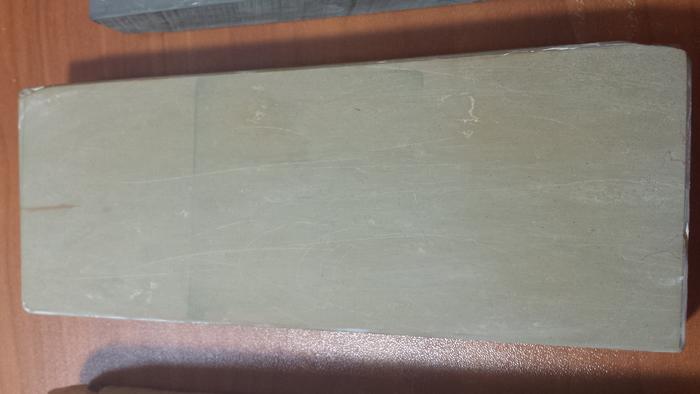

Your diamond plate needs to look like the attached image! It doesn't scratch.

JNats can be very smooth feeling and sometimes it's difficult to understand just how abrasive a really good one is. So yes if you get some visible scratches, or ones that aren't, the tomo can work them down pretty quickly. I wouldn't want to start with scratches from an "un-mellowed" plate especially a 325/400/600.

Cheers, Steve

-

09-07-2015, 06:36 PM #67Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

+1 on the soft JNS tomo. They are wonderful. I have always used a dmt 325 to make slurry, but I haven't done that in ages because I now have so many tomo nagura that I don't need to create slurry from my base stones. Here are my four jnats. From left to right, nakayama kitta, nakayama maruka, shuobudani 100, nakayama that I don't know much about. They all work really well, the kitta is my newest one and I'm still trying new things with it. The shuobudani 100 was my first, and it is so easy to use! The two nagura farthest right are my newest. The small one is a nakayama and the other one is supposed to be a koma. Whatever it is, it works really, really well

there are some scratches on my hones, a few months ago I was experimenting with a handful of nagura, and most of them were harder than my stones.

there are some scratches on my hones, a few months ago I was experimenting with a handful of nagura, and most of them were harder than my stones.

-

09-07-2015, 06:45 PM #68Member

- Join Date

- Aug 2015

- Location

- texas

- Posts

- 35

Thanked: 3

Thats another great idea, to use a worn out plate to test the hone and then progress to a nagura! Yes using a new coarse diamond plate could be detrimental and I can deduce from Alex'x video that a worn out plate is being used. I guess there is no such thing as the best way, there are different ways and preferences to a great result. Again great is also subjective and relative on a person. IMO

-

09-07-2015, 06:53 PM #69Member

- Join Date

- Aug 2015

- Location

- texas

- Posts

- 35

Thanked: 3

-

09-08-2015, 12:23 AM #70

You are covering a lot of bases here. Let me ask you. With the DMT slurry, what grit was the DMT and what were the negative effects?

When I use a tomonagura on the surface of my base stone I am roughing up the surface on purpose in an effort to release the slurry particles. If the base stone is super level 5+++ the idea is that the tomonagura nagura will get roughed up so that the grit comes from the nagura. With a medium hard base stone it is easier to match up a nagura that is compatible in a way that both the base and the nagura contribute some of their slurry and both base and tomo get roughed up. With softer base stones they will sometimes self slurry.

It is all same with a white Mikawa type nagura, and the same with a Diamond Nagura or a tomonagura, that is what they are for and if they did not rough up the surface you would not use them because with no abrasion there would be no slurry provided to speed up the cutting action on your razors.

This is exactly what happening to a lot of fellows here who bought level 5++ or harder base stones and were provided cheap level 5++ tomonagura. Each stone scratched the other in an uncontrolled and uncompromising way.

The idea in my opinion in using any nagura is to rough up the stone in a controlled way, not too rough and not too smooth but instead tailored to the job at hand. Usually the natural nagura is a slightly coarser stone to begin with and less expensive per gram, but it can be advantageous to sometimes use a nagura that is finer than your base stone and hardly ever or rarely advantageous to use a piece of the base stone as a nagura. Quality natural nagura are often more expensive per gram than your base stone. In either way you are using up grit, depleting part of one or both of your stone to perform a task. Every action requires energy, and the fuel of honing stones is their grit. If you don't use your base stone grit but choose to substitute an alternate grit source like a tomonagura, well that is fine too. But no matter the source if you want to remove steel with a Jnat, loose slurry is your ticket.

Softer nagura is not necessarily better nagura, high quality nagura just like base stones comes down to percentage of grit per weight which in the right hands can represent cutting speed. We are all here interested in cutting speed whether we admit it or not. Three days to set a bevel and 4 more days to finish it. Or one day to set and two 24 hour days to finish it off to shave ready. No one here is interested in doing that week after week. Cutting speed and grit quality and skill and technique is what honing razors is all about.

Many super hard 5+++ stones are grit rich but you cannot access the grit without a diamond nagura. If you want to just use your Japanese Natural 25mm thick super hard and expensive stone as a polishing stone you might just as well use an Arkansas with a tomonagura or Mikawa nagura, you will get about the same results because it will be the nagura doing all of the cutting while the base stone just acts as a polisher or burnisher platform. A medium hard grit rich and expensive Japanese natural will easily contribute some of its own grit and is more flexible to use because it can act as a platform for your nagura while at the same time it will provide some of the grit in the mix.

I have gotten some amazing edges from a level 5++ or 5+++ Jnat's with a really fine diamond plate generated slurry. These very hard stone slurries can be very aggressive in the initial stage and when breaking down can leave a fine hazy finish on almost any blade. At the same time I have gotten some really amazing edges off a level 5+++ stone by using nagura and Mikawa nagura. It is all a matter of style.

I will not deny that a diamond plate scratches my base stone, but I will tell you that my and your stones heal surprising easy. The shallow scratches left from a worn out #1200 Atoma are so shallow that you cannot see them. Those from a new DMT 300 you can see and I do not know why anyone would use that coarse a diamond plate anyhow for raising a slurry. The scratches left from a mellow Diamond Nagura will not be noticed and will heal as soon as you touch the stone with a tomonagura. The same mechanical healing happens after using a DMT but it takes longer or more rubbing. I only know of one person who wears out a Japanese natural stone through regular use and he is a furniture maker. I would like to meet a person from this forum who has worn out a Jnat. Most of us will die with 80% or so of the thickness of our stones remaining.

Bladesmiths love diamond plates for shaping steel, stone users love diamond plates for lapping (shaping stone). This indicates to me that if stone or blade users 200 years ago had cool diamond plates like we do, they would have found and developed some creative uses of them and surely some of them would have used them to raise a slurry. The rumor that was floating around 3 or 4 years ago that "No one in Japan uses diamond plates to raise a slurry" was stupid. Of course people did, and more do now, just like here in the the U.S. and Europe. Some fellows stick with the old party line because they feel safe but creative craftspeople are always looking for new tools and new ways to use tools.

Next time you lap your stone, try and use the slurry instead of just washing it down the drain.

Alex

-

The Following User Says Thank You to alx For This Useful Post:

Dcaddo1 (09-08-2015)

79Likes

79Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote