Results 11 to 20 of 63

-

02-21-2018, 01:12 PM #11Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

That would be very dependent on hardness. A razor at the top end of the scale would be as near as impervious to a natural bevel setting stone so as to be almost impossible to set a bevel with one. For a razor closer to 58/60 Rc it would not be that big of a deal.

-

02-21-2018, 01:24 PM #12

In truth, I have the same question. In fact, steel at 65RC, in a commercial scale would not only be impossible to make and sell, the sheer number of blades that would fail would be huge.

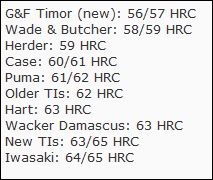

Here is an old photo I copied here from the forum on average hardness of razor manufacturers;

And the above chart is for western style razors, kamisori were going a bit higher still. I'm baffled on how but more importantly, why would anyone do that.

As for the "it's impossible to get steel harder than 66RC", it's simply not true; there is no law similar to absolute zero or speed of light; 1% carbon, correct heat treatment, quench, temper, dip in liquid Helium to maximize martensite formation & voila! You can do it yourself, with enough money, practice and patience. As for being chippy, I'm sure you are right, that thing would be more like cermet than steel. I haven't tested such a piece although I do hope to.

I'm not saying that I have seen, or verified its existence. Only that at some point I read about it, and thought "holy mother of God, how was that done and why?"

We have some very capable blacksmiths, quite possibly some of the best of our age here in the forum who know their stuff, usually in the "forge" section. I enjoy reading about their accomplishments, you can say they are the "astronauts" who walk the moon, I'm the lowly "astrologist" watching from afar.

-

The Following User Says Thank You to Vasilis For This Useful Post:

Substance (02-21-2018)

-

02-21-2018, 04:44 PM #13

There's a Turkish sandstone from Bolu, just south of the Black Sea, known as a "Bolu" stone. I haven't used it with razors; but a couple of summers ago, I gave one to a friend in France, and we found that it works well for starting the edges of kitchen knives and generates lots of swarf. Pretty even feel that might translate well to razors. Used with olive oil.

Last edited by Brontosaurus; 02-21-2018 at 04:47 PM.

Striving to be brief, I become obscure. --Horace

-

The Following User Says Thank You to Brontosaurus For This Useful Post:

Vasilis (02-22-2018)

-

02-21-2018, 06:39 PM #14Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

-

02-21-2018, 06:43 PM #15

I got the chart from Neil Miller, may he rest in peace. I doubt you'll find a person who double checked his data more than him, I've been in many occasions where I assumed something only to be scolded by him for not being able to verify my thoughts' kind of like what's happening here. Anyway, the above chart is as legitimate as can be, for that I'm sure.

Edit; eKretz, if you have different information, or any of the above measurements are different from yours being a toolmaker, please share your knowledge. That's what this forum is for, and I meant no disrespect, naturally. It's the opposite in fact.Last edited by Vasilis; 02-21-2018 at 06:48 PM.

-

02-21-2018, 10:24 PM #16

Skilled forging & heat treat are crucial for high hardness steels to not be chippy.

The highest control anyone has over those 2 things is making your own steel. Iwasaki tamahagane razors come the closest to that.

I have had one pass thru my hands that was ID'd as HV 860 on its box but I know they came even harder.

Iwasaki preferred a Vickers tester over Rockwell but I believe that's close to HRC 65.

Took longer to hone but far from impossible using fast cutting stones. Absolutely no chipping at any stage tho I have seen plenty of softer customs in the low 60's HRC that were chippy.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

02-21-2018, 10:37 PM #17Senior Member

- Join Date

- Mar 2013

- Location

- Sydney Australia

- Posts

- 173

Thanked: 40

The numbers for the Iwasaki razor are about right, this thread shows one (factory tested by the maker) at 860 HV (https://straightrazorpalace.com/cust...tml#post740753) which converts to about 65 HRC, it is the same razor OZ referred to above.

67 HRC seems to be the upper limit, this thread, @ post 14 reports knives at 66-67 HRC (https://straightrazorpalace.com/razo...uestion-2.html).

F.Dick precision files are rated the same (see https://www.fine-tools.com/feile2.html), the steel used here would not be dissimilar to that used in razors

In both cases it would be safe to assume that the manufactures have put in considerable effort and great expense to get the knives/files as hard as practically possible, the knives likely for bragging rights and the files for superior performance.

-

The Following User Says Thank You to DrDalton For This Useful Post:

Vasilis (02-22-2018)

-

02-21-2018, 11:40 PM #18Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

I guess my point is already made. The claim that some razors were hardened "at or over 67 Rc" is unsubstantiated and very unlikely. I have no problem with a claim of 64/65 Rc. Testing a razor at or even near the cutting edge is virtually impossible because the steel is too thin for an accurate test by any method I've heard of. 67 Rc is the absolute tops I've ever heard of for carbon steel, and that's basically with zero tempering, which makes for extreme fragility. With a razor production attempt at this level, one would be likely to scrap most of the production due to cracking of the blade during heat treat. Any knives harder or even probably most of the knives at this level are likely alloys similar to ZDP.

-

02-22-2018, 12:09 AM #19

-

The Following User Says Thank You to onimaru55 For This Useful Post:

Vasilis (02-22-2018)

-

02-22-2018, 12:43 AM #20

Just to prove that I did not imagined it, and mainly to myself to be honest, but sharing my results won't hurt, here are the three threads searching for " HRC 67 " in the forum

https://straightrazorpalace.com/auct...ern-style.html

https://straightrazorpalace.com/honi...ds-honing.html &

https://straightrazorpalace.com/begi...bly-blade.html

You are right about the files too, I have read that they are tempered that high. Or close to that. I'm not starting any heated arguments, nor did I intend to from the beginning. I just said that I've read about the existence of such razors somewhere, quite possibly above. Where, again, I'm not blaming the ones saying it, I bet there were such razors/knives/files-pieces of steel.

An hyperbole for going higher than that as it turns out, so, I'm sorry everyone!

My original point was "razor are made to be hard". Also, scratching a razor is easy, even wiping one from common relatively-non-abrasives-containing dust could do it. But you can also scratch glass with a corner from a piece of calcite (crystallized CaCO3/calcium carbonate); the Calcite will be destroyed, and a tiny line will appear on the glass, that's not real scratching nor true Mohs hardness testing. I have done the exact above thing, that's why I'm mentioning it.

The DIY Mohs hardness test can be used for knives although the results are subjective; take a knife you know is tempered to above 50 and scratch another one, on the side (no clad steel, san mai and all that stuff, just a classic "monosteel" knife) with the tip to the side of the other, in a way that you'll do the minimal damage to the "known" knife but you will be able to see/feel the knife you are holding biting into/hear the other knife giving in and then feeling the line with your finger. It's an invasive method for sure, but if you don't have any other choices it answers the question "is that piece of steel any good?" quickly. If you are a blacksmith in your smith though, there are far far better options.

By the way I think we went quite off topic.

50Likes

50Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote