Results 41 to 50 of 63

-

02-24-2018, 04:54 PM #41

No need for ad hominem discussions fellas, I know we're here with a shared interest in everything straight razors and are very passionate about it

-

02-24-2018, 05:28 PM #42Member

- Join Date

- Jun 2013

- Location

- Toluca, Mexico

- Posts

- 56

Thanked: 1

Sorry but, at least from myself, I was not pushing any blame on anyone… That is not "ad hominem"!. And I must be shure, Vasilis, being greek must know better about that argument. Anyway… As said in The Godfather: "we are not animals!". hehehehe.

And then there is Vangelis…

-

02-24-2018, 06:16 PM #43

-

02-24-2018, 11:01 PM #44Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

There seem to be some posters in the discussion who are beyond their depth (and being sarcastic/rude about what they don't understand no less). There are no "carbide tipped" blades being discussed here. Carbides form naturally in certain steel alloys when they are hardened. Any alloy of steel that contains a certain percentage of tungsten or vanadium or other carbide forming alloys will naturally form these carbides, and they are a pain to deal with. Most razors are made from plain unalloyed steel, so most razor users don't have to worry about these issues.

The discussion did segue into knife steel and hardness - and this is where that comes more into play. There are also some low quality razors made whose makers didn't have very tight control over their alloys - namely a lot of blades from Pakistan I have seen this issue with - and these can have carbide issues and can be a pain to hone.

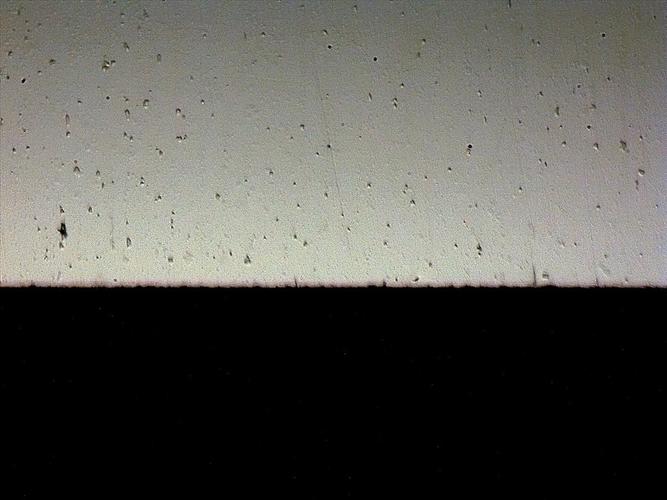

Here is a photo of a razor made from a high tungsten alloy - you can clearly see the very hard carbide particles sticking out of the steel that weren't cut by the synthetic hone.

-

The Following User Says Thank You to eKretz For This Useful Post:

Vasilis (02-24-2018)

-

02-24-2018, 11:36 PM #45

While we are at it, did you shave with this or some kind of a blade with such carbides?

Do you detect any unfriendliness to the skin from their presence?

Martensite is a carbide too, though softer than the ones from Vanadium/Tungsten/Tantalum/Niobium etc. Carbon prefers these elements instead of iron to form the carbides, otherwise we wouldn't have them in there.

Hardening/tempering changes their size' a big crystal is less friendly and generally useful than a small one. So, if done correctly, assuming such a thing is possible, will it be detectable in shaving enjoyment? I'm not asking for references, just an opinion.

-

02-24-2018, 11:55 PM #46Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Yes, I have shaved with it often. I can't discern any difference in the feel on my face from any other well honed razor. This particular razor is probably in the neighborhood of 64/65 Rc. It is a little chippy at narrower angles - I prefer to keep it pretty close to 18° included for longevity. BTW, those carbides in my last image are on the order of 4-5 microns in diameter. The higher the percentage of alloying element, the more carbides will be formed.

As I mentioned, I have also run into production razors with considerable carbide formation - mainly those from Pakistan. Although they are sometimes a pain to hone, once the edge is nailed down, they shave just as well as any other razor. I had a very late run Filly with this issue.Last edited by eKretz; 02-24-2018 at 11:58 PM.

-

The Following User Says Thank You to eKretz For This Useful Post:

Vasilis (02-25-2018)

-

02-25-2018, 12:09 AM #47illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

-

02-25-2018, 12:16 AM #48

-

02-25-2018, 01:04 AM #49Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

The parts that look like pits to you are the shadows behind the carbides that are sticking out. The lighting source in the photo is from almost directly below the razor. Often, when honing steels with these carbides, they will be ripped out, leaving pits/holes - that may well be what you saw on the razor you mentioned. This particular honing was done gently on a very fine synthetic hone. Coarser hones ripped the carbides right out and left pits.

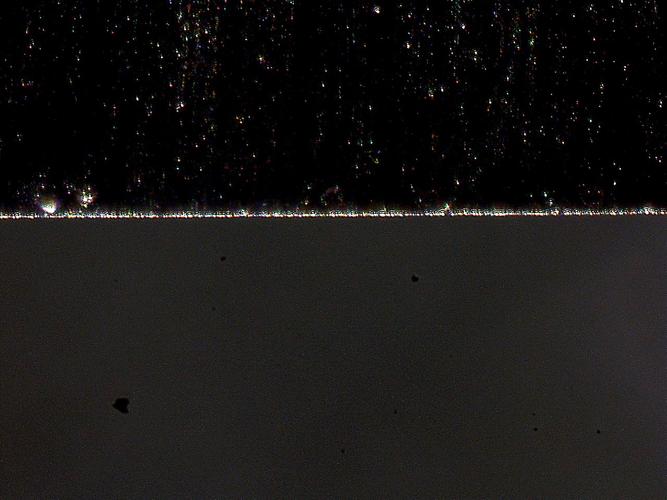

Here is a photo showing the carbides lit up with a slightly different light source angle.

Last edited by eKretz; 02-25-2018 at 01:19 AM.

-

The Following User Says Thank You to eKretz For This Useful Post:

Utopian (02-25-2018)

-

02-25-2018, 01:14 AM #50Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

No, this image is of a razor I made from T8 steel (~14% tungsten). Here's a link to the rest of the specs:

https://www.google.com/amp/s/www.azo...ArticleID=9154Last edited by eKretz; 02-25-2018 at 01:17 AM.

50Likes

50Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote