Results 51 to 60 of 86

-

01-18-2024, 06:44 PM #51

-

01-18-2024, 11:23 PM #52Senior Member

- Join Date

- Jul 2023

- Posts

- 140

Thanked: 0

Thanks for reviewing the thread again and providing the drawings.

1). I've no doubt your method will solve my problem better so that I don't even need a 30K edge. My beard isn't that thick and 2 vertical/horizontal passes would clear it nicely, leaving very little areas to detail. I guess it will take quite a few attempts before I can manage it.

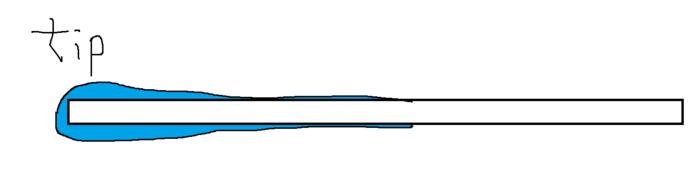

2). I think we are on the same page. I know how to hone a curved edge and I have done a lot with knives, but not much experiences with razors. Regarding the the Titan, the bevel angle was too obtuse, I still feel it is a little bit too obtuse even after thinning the spines. And the spine was not only too thick but also not even. It was much thicker at the tip. See pics below for what exactly I meant. Excuse me for the bad drawing, had to use mspaint with mouse.

Attachment 350978

Attachment 350979

I could have done rolling/rocking strokes at the edges of the stone to get it honed up, but knowing what to do is one thing, getting it done as expected is another. As I didn't like the ground already, I would rather get the geometries right, straighten the edge and do whatever I do with straight edge ones. Then I realized that I could not get it done quickly enough and I need a good diamond plate with continues surface. So I put it away and forgot it completely until last week. Since I had to fix the spine anyway, so I straighten the edge too.Last edited by mrjin; 01-18-2024 at 11:36 PM.

-

01-18-2024, 11:24 PM #53Senior Member

- Join Date

- Jul 2023

- Posts

- 140

Thanked: 0

-

01-18-2024, 11:27 PM #54Senior Member

- Join Date

- Jul 2023

- Posts

- 140

Thanked: 0

Thanks. I guess I've done it right. Now I get the sharpness and smoothness I wanted. The only issue was that S30K could not cut stainless steel efficiently. Stropping on diamonds bridged the gap. Never imagined that.

But still, I don't quite like the half hollow ground. I'll probably continue to shave with it to see if it hold the edge well and whether it micro chips. Or maybe I should just dry it and put it into the box and pick up the Clauss.Last edited by mrjin; 01-18-2024 at 11:30 PM.

-

01-19-2024, 03:39 AM #55

My vote is for the Clauss. I like a challenge as much as the next guy but give yourself a chance to succeed...so to speak. Even if you get that thing shave ready it is still is not as good as the Clauss.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

01-21-2024, 07:05 AM #56Senior Member

- Join Date

- Jul 2023

- Posts

- 140

Thanked: 0

-

01-21-2024, 12:12 PM #57

I never looked that deep into Clauss. But I'll say this. That's a nice one, and now you have a good razor that will shave and hold an excellent edge.

Mike

-

01-21-2024, 06:17 PM #58

Outstanding razor! You'll like that one!

Semper Fi !

John

-

01-22-2024, 03:45 AM #59

Looks like a larger Clauss. 6/8? It seems the edge took some light in the middle. Beware the excessive buffer. It's aweful shiny for it's age. More closer-ups of the edge?

Hard stuff. Tough to hone. Holds an edge very nicely. I have a couple I need to get to!

GD smoker.....unless?"Don't be stubborn. You are missing out."

I rest my case.

-

01-22-2024, 04:01 AM #60

Yeah, that one looks good and in good shape. Maybe I am not getting as good resolution as you Tom. I can't see the light on the edge you mean but at least the lines don't look rounded off on the angle breaks from what I can see. Not much hone wear either.

Take that one to your 30k and you should get an eye popper. Just make sure to go thoroughly up through the progression and the 30k should make that thing smoke.Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

146Likes

146Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote