Results 101 to 107 of 107

Thread: Shoobie Doobie Asagi

-

07-15-2011, 01:13 AM #101Senior Member

- Join Date

- Dec 2009

- Posts

- 217

Thanked: 35

Stefan, I sharpen both japanese and western plane blades.

Why can't one compare the hardness of a coticule or C12k to a Jnat. Hardness

is hardness AFAIK.

Makes sense about the colour of the slurry, indeed if both stones have the same colour,

it will be very difficult to see.

I like your scratch test. What about rubbing two stones together when completely dry?

Wouldn't the softer stone get a rougher surface?

Do you think calculating the density has any relevance? For example one stone

is 20cm by by 5cm by 5cm and weighs 1000grams. So the stone is 500 cm3 volume.

Weight per cm3:

1000/500=2grams

the other stone is .........

.............

1.9grams per cm3. So this stone is softer than the above. Could this work?

Sharpman

1000/480

-

07-15-2011, 01:33 AM #102I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

the binders are different so no it is not the same. The absolute way to test is to measure the hardness of the grit particles.

try and see if it will work but I feel wet will be betterI like your scratch test. What about rubbing two stones together when completely dry?

Wouldn't the softer stone get a rougher surface?

The hardness also is determined by how compact the stone is, the very hard ones are also very very fine because they are more compressed than the others. So if you have two identical size stones(of the same type J-nar , C12k etc.) the finer one will also be heavier.Do you think calculating the density has any relevance? For example one stone

is 20cm by by 5cm by 5cm and weighs 1000grams. So the stone is 500 cm3 volume.

Weight per cm3:

1000/500=2grams

the other stone is .........

.............

1.9grams per cm3. So this stone is softer than the above. Could this work?

Sharpman

1000/480

As far as planes there are two things to consider, aesthetics and practicality.

Japanese planes are two metal construction, soft iron and hard steel. When you use a Jnat to sharpen if you care about good finish on the soft iron you need a stone that is not going to scratch but at the same time is hard enough to provide flat bevel. Typical plane stone will be lvl 4.5, but if you want a very good stone you need lvl 5 or more which will be very expensive. Such hard stone will also be good for razor so if you are looking for multi-functional stone that will work for your tools and razors you need to prepare to spend money.

The reason your SS does not work well on your planes is it is too soft, you need harder synthetic such as GS or Shapton Pro ( I hear the Pros are very hard but could be wrong). If you want to go the natural stone way, you have a few choices, Arkansas stones are great stones for tools , or you can go for coticule, or you can go for one mid level prepolisher and in any of the cases one very hard finisher. Another finsher option would be a CF.Stefan

-

07-15-2011, 07:21 AM #103

Hi Sharpman,

that´s where you´re off track. When you say hardness is hardness, then what is hardness?Why can't one compare the hardness of a coticule or C12k to a Jnat. Hardness

is hardness AFAIK.

I have a bit of a metallurgical and material science background and can tell you it is not that simple.

Hardness is not clearly defined and cannot be measured directly. Especially when you take into consideration that a sharpening stone is a mixture

of several compounds withvery different hardness.

There are several ways of telling a value for hardness like HRC, Vickers (indention), Mohs (scratching) etc.

and all of these values are incomparable.

That´s because they are committed to a specific cause

So technically we have to make our own system of telling what is hardness for our cause.

Now that I know where you going at, I can help you with that.

Our cause is now freehandsharpening and we want to test if a stone can withstand the

indention or cutting of a badly angled blade (ie. will it get gouged?).

Of all my Sharpening stones I have to be most carefull with my naniwas when freehandsharpening.

There is no way you gouge a Shapton, or an Asagi, or a Nakayama.

My Oohira is far beyond that as well. And never in live will the Chinese hone be cut into!

For this purpose (resistance to gouge) I would rate these the following:

Naniwas: 2-3 (gouge easily, but resist wear) [Naniwa 5k: 2; Naniwa 8k: 2,5; Naniwa 10k 3]

Shaptons: 4-5 (resistant)

Any natural I had so far: 5 (100% resistant) *

When I speak of density I do not necessarily speak of specific gravity, but of the closeness of the particles.

Again there is a difference in makro and micro scales.

In micro scales the atoms and molecules of a substanze have a specific distance to each other which closely relates to the specific gravity we can measure.

But a sharpening stone may consist of grains of matter. In each grain, the particles are packed according to their natural specific gravity.

But if the grain itself has a distance to it, then the Volume is increased.

Let me explain with polystyrene, the substance Styrofoam is made of.

What weighs more, 1 m³ (Volume) of Water, or 1 m³ (Volume) of Styrofoam?

Of course we know the answer, it´s water.

Water has a specific gravity of around 980 kg/m³. 1 m³ Water weighs in at around 1.000 kg.

Styrofoam is made entirely out of polystyrene which has a specific gravity of 1050 kg/m3.

So 1 m³ polystyrene weighs more than 1m³ water! How is that possible?

The polystyrene gets foamed, air or gas is trapped between little grains of polystyrene.

The volume is increased but the mass stays nearly constant.

So the corrected density of Styrofoam is 20 kg/m³, 1 m³ will weigh in at about 20kg.

Apply this to a sharpening stone.

There are grains, and when I speak of density of a stone I speak of how closely these grains are packed

*but remember:

Natural stones do vary. I do not know of a sginle someone who gouged his chinese 12k, thoughLast edited by Lesslemming; 07-15-2011 at 07:44 AM.

-

07-16-2011, 01:37 PM #104

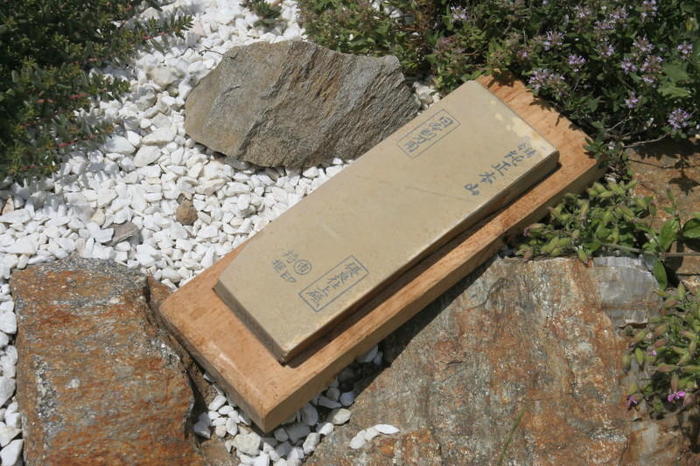

Back to J-Nats and the marvelous Shoubudani, I got some pictures I want to share with you

The first picture shows my japanese naturals collection.

From left to right we have the following stones:

- Suita Kiita, for sharpening kitchen knives

- Oohira Asagi, with light green

- Nakayama Kiita, excellent fineness

- Shoubudani Asagi, probably my personal favourite

And these Nagura, or rubbing stones

- Two large medium fine stones (brwon-red and light asagi)

- Uchigomori Suita (on top of the bigger light asagi)

- Tsushima Nagura, the black square one (medium-fine)

- Asano Mejiro Nagura, quite fine

- Two Tomonagura, the black chip and the blue greenish one

Some pictures of the surface of the dark asagi of the Shoubudani, note the scratches.

The stone is still in the condition it came in, and there is nothing that bothers

or changes the performance of the stone. These look far worse then they are

Now My Nakayama Kiita with Nashiji, Maruka/Maruichi and Nihonkamisori stamp.

This picture must have been taken eons ago, by the original owner.

Since it is not my picture I hope he allows me to present it here

straightrazorguy.net

At last a picture of the remaining stamp on the bottom.

Note how the wooden base has changed over the last couple of years (maybe 4?)

-

07-16-2011, 03:54 PM #105Senior Member

- Join Date

- Jan 2008

- Location

- Northern California

- Posts

- 1,301

Thanked: 267

Since this thread has some J-Nat heavy weights on board I have a question about hardness verses the feedback that stones have. I have a Nakayama Asagi that is a Maruka. It is a very dense stone with a little bit of a green tint. The slurry is hard to obtain even with a diamond card. When I am doing the final finish I use a very light slurry but then I go to just water. The feeling that I get from the stone, with water only, is very much like a Coticule and the bevel has a diamond white mirror in appearance and is extremely keen.

So on to the question....Normally when speaking of Naturals the harder they are the harsher the feed back. Nothing close to the buttery feel that one gets from a Coticule for instance. This stone has very much a buttery or oily feel to it when honing, but why?

Later,

Richard

-

07-17-2011, 10:13 AM #106

We are kind of Hijacking the thread, since it is dedicated to the Shoubudani.

DrNaka your Blog is highly interesting, maybe you want to open a thread for it.

I think this way most people will read it and benefit from it.

I have a question for you.

The Kasumi finish of my knives plays an important role for me.

I found that if I sharpened the knife on my japanese naturals in only one direction (i.e. into the edge, dge leading)

and used the fingerstones in an angular direction (so the scratch pattern is 90° to the original)

the contrast between the iron layer and the steel layer becomes very crisp.

(I am talking about three layerd knifes)

Have you noticed something similar, or is it just me?

Hello Richard,

I don´t know what you mean with harsh feedback. Usually, from very hard stones you should get next to none feedback, ie. it should feel like glass.

I have owned a couple of Coticules and think they do come in different hardness and feedbacks just like the Japanese do.

My Oohira gives a smooth and oily feedback, whereas my Nakayama Kiita gives a velvety feeling and the Shoubu gives an extremely smooth and a little (!) glassy feedback.

My PHIG gives no feedback and feels like glass or marble.

So technically every imaginable feedback is possible within the range of variety of natural stones, I think

-

The Following User Says Thank You to Lesslemming For This Useful Post:

zib (07-17-2011)

-

07-17-2011, 01:50 PM #107

Guys, Your getting off topic here and you are hijacking my thread. This thread is about the Shoubudani Hone, Not Finger hones. Please start a new thread. Thank you....

I moved all the finger hones theards to "Finger Hones"Last edited by zib; 07-17-2011 at 02:01 PM.

We have assumed control !

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote