Results 81 to 90 of 126

-

03-18-2016, 10:51 AM #81

Wondering if I should, though. Was expecting a harsh, but reasonably cutting shave (granted, I've never tried shaving off a 2K or lower - always got up to at least 4K/8K). I'm concerned that I don't have a good bevel set, and if not, don't want to spend time polishing it.

Regards,

PCM

-

03-18-2016, 02:35 PM #82Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,401

Thanked: 4822

I was mostly wanting you to check and see if the razor would shave at that angle. With normal geometry you should be able to shave as soon as the bevel is set. It is not a pleasant shave but it should mow whiskers. It should feel course and harsh on your skin, but still do what a shaving edge should do. Now I am curious if it is your honing or the angle that is not allowing it to shave. I would think some more 2K work before any thing else.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

pcm (03-18-2016)

-

03-18-2016, 04:00 PM #83Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Did you strop on leather, before the shave?

Strop on linen, 20-30 laps, joint the edge and re-set on the 2k. I would be more concerned with the steel than the angle. The steel at the toe and heel does look different than the middle. It could be that more metal has been removed from the middle.

Stropping on linen will straighten the edge and remove any burrs, it will also stress the edge and if weak, may give you a hint of failure.

I strop on Chrome Oxide canvas after 1k, then joint and re-set the edge, I also strop on Canvas before the finish stone.

On problem edges where the steel looks different across the edge, I joint frequently until I get uniform steel across the edge. Do you need to, maybe not, but any time you put into setting and perfecting the bevel, is time well spent, because if the edge fails after polishing you just have to come back and reset or fight it all the way… and then start over.

Last night I honed an old Wade Butcher, with a crumbly heel and steel that look much like yours at the edge, only worst. I ended up lightly bread-knifing on a 1k diamond plate and reshaping the heel to get to good steel after fighting it for a while on a hard Nubatama 1k.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (03-18-2016)

-

03-18-2016, 05:52 PM #84Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

We touched on this earlier, but perhaps a little elaboration may help you.

You don’t have to make full blade width strokes every time. Often, especially when making repairs, which are what you are doing, concentration honing is helpful in focusing on a specific area, heel or toe.

Just do back and forth strokes on the same area of the bevel to make the correction, whatever it takes. You may end up with a faceted edge but that can easily be blended with a smooth X stroke.

So spend some time on the heel and toe until you get a good strong edge there, then blend.

If you hone the heel and toe the middle will follow.Last edited by Euclid440; 03-19-2016 at 01:33 AM.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (03-18-2016)

-

03-18-2016, 10:59 PM #85

Yeah, my expectation was that it would be a harsh shave, but I found that there was no irritation, but it was not cutting hairs much at all.

Granted, it's been a year since I shave with this razor (my only near wedge), and even then, I only used it about 20 times, so I'm not sure if I need to alter my shaving technique either.Regards,

PCM

-

03-18-2016, 11:03 PM #86

-

03-18-2016, 11:06 PM #87

-

03-19-2016, 12:03 AM #88Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Straight back and forth, half lap strokes with the stria perpendicular to the edge. This is correction work, not a regular honing technique.

Work a section at a time, keep count of the laps and do the same on the opposite side, I usually do 10 or 20, so your edge is in the middle of the blade.

Once you get to good steel that looks like the rest or the bevel, then blend them to a smooth bevel and edge, with an X stroke.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (03-19-2016)

-

03-19-2016, 01:16 AM #89

AH, I had already honed tonight, before I saw your post Euclid440, but I think I'm heading in the same direction.

I decided to focus on the toe and heel. I dropped down to the 1K Norton (as it seems more aggressive than the 2k SS), kept 5 layers, and decided to go straight back and forth (1 stroke in each direction), only working on the front and back 1/3 of the blade at a time. Neglected the center.

I closely monitored the water in front of the edge to see if it was pushing. I finally got it to move the water well, but found out a few things...

First, I laid the blade on the stone and as expected, the heel, and a large area of the toe do not touch. To get the heel to touch, the toe must raise about 2mm. To get the toe to touch on the end, I must raise the heel 3+mm!

Second, I found that on one side, I was getting a second bevel on the toe. I was concerned that I was maybe lifting the spine a bit, when raising up the heel. So, I jointed the edge on the corner of the stone lightly, and the did it again, with a finger on the to, to make sure the heel was down. Not sure I did enough laps that way - kept light pressure otherwise - as the double bevel is still there.

Stria is straight, and the heel looks better than the toe, but it certainly is a real challenge to get it to touch, especially over a half inch region of the toe, where there is the curve.

Looking at the edge, I see some shiny spots in the center, though I didn't hone there much at all. The bevel seems to meet (except maybe at the heel), but it doesn't feel too sharp to TPT. I need to pull out one of my other razors and compare.

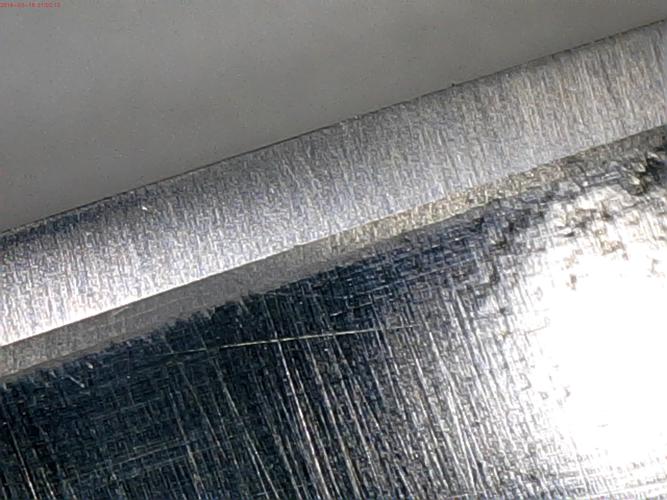

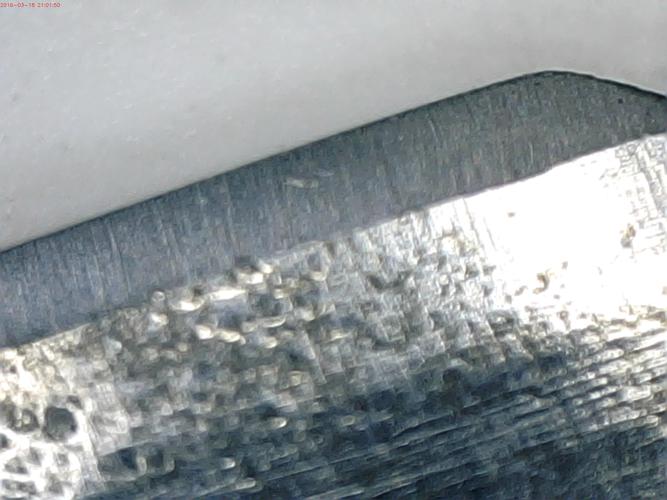

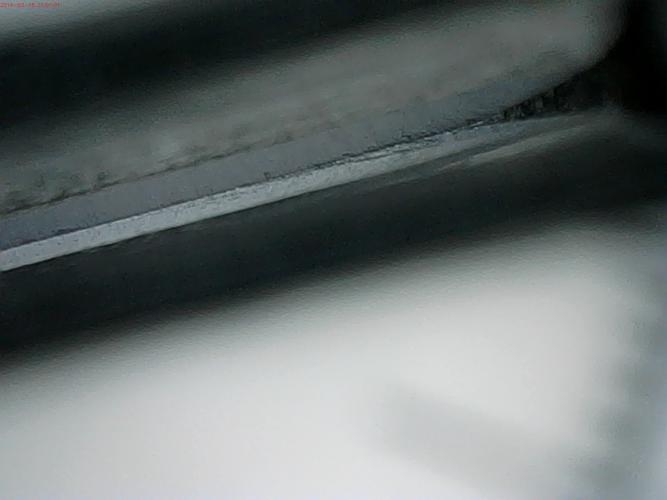

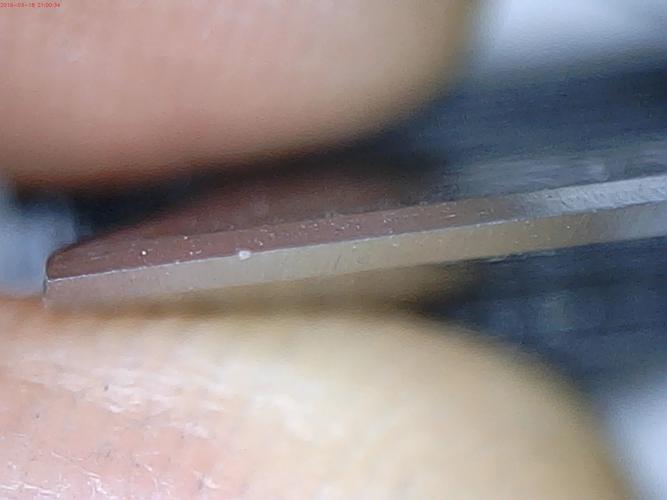

Here are some spot picts at low magnification:

Were you suggestion doing a number of strokes on one side and then switch to the other? I've been alternating.Regards,

PCM

-

03-19-2016, 01:19 AM #90

Picture 3 shows the double bevel. I don't see it on the other side (picture 4) of toe. The heel looks pretty good from the sides, though there is only a 1/4" of curve there, and it is easier to keep the spine on the stone on the side of my hand.

Regards,

PCM

117Likes

117Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote