Results 61 to 70 of 144

Thread: Dovo’s honing method

-

04-29-2021, 03:19 PM #61

I think we can easily find common ground in the fact we all enjoy a well produced quality razor. As I see it, a razor provided with a straight edge or a slight smile; certainly not with a frown.

And one that is truly shave ready without functional or practical hindrances created by the manufacturer.

Aside from a well produced razor that is perfectly functional, straight razor shaving is highly subjective. Even the finisher preference varies A LOT between folks and that's something that can easily be worked out by folks themselves. Fundamental problems with the razor can't.

The fact there has been many reports on fundamental issues with modernly produced razors in Solingen is what bothers people, and rightfully so, folks expect better from a town called Solingen and also from a name like Dovo.

As a while ago when I started shaving everybody was recommending entry level Dovo razors.

It sounds idealistic, but often times fundamental perfection gets lost in modern day times due to a variety of reasons; which is eventually a sad thing.

We are no doubt a nostalgic bunch that admire the art of straight razors, etc. And since we're all on a forum, we're a bit of perfectionists as well, maybe.Last edited by TristanLudlow; 04-29-2021 at 03:25 PM.

-

04-29-2021, 03:53 PM #62Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I hone a lot of new Dovo and TI razors, the issue is not that they are not precisely ground, they can be repaired easily, properly honed and made to shave well.

The issue is that Dovo and a few trolls claim that they are “Shave Ready”, and they are not. If a new shaver were to receive the razor that Glenn posted photos of, he would be sorely disappointed and likely never learn to shave with that razor.

I once read an article about the problem with cheap, poorly made golf clubs. And that someone trying to learn to play golf with poorly made clubs will just give up on the sport and never learn the difference a quality set of clubs can make.

That Dovo claims their razors are “Shave Ready” hurts your industry more than the imperfect grinding. With hand tools, chisels, plane blades and knives, everyone understands that the end user must hone the tool prior to use, with possibly one or two exceptions, (and you pay for that). There is no expectation of a user ready tool. And every woodworking school first teaches tool preparation and honing before they are taught how to use the tools.

The solution is not high dollar, Precision CNC, in-process laser measuring manufacturing, but their claims. Your industry’s ladder is on the wrong wall and the solution is simple, stop claiming the razors are shave ready, if they are not, or teach your people how to hone.

Clearly the “Honers” at Dovo are not shaving with those razors and the master grinders that do shave with these razors, are not honing the razors.Last edited by Euclid440; 04-29-2021 at 03:57 PM.

-

04-29-2021, 04:01 PM #63At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,030

- Blog Entries

- 1

Thanked: 13245

Dear Friend: This is making it worse for you and what you are promoting, in fact you sound just like Jarrod with his junk science. same inaccurate math pulled from nether regions, in fact your writing style is exactly the same....

Yes your doing it wrong, and you should know better, don't try and pee and tell everyone it is raining

Your factory edges are not up to a standard that was achieved for 100's of years on millions of razors it is that simple...

I for one appreciate your Honing ineptitude it makes me beer money

I am sure there are Vendors that do not, lets be real here

Your ineptitude is what is killing the SR market again, the worst thing that can happen is a new shaver gets your junk science honed edge, and NEVER returns to SR shaving, another person that thinks we are all lying about the great shaves we get because you can't learn to hone and refuse to admit it..

Try that somewhere else, you ain't doing well so far on the 3 biggest SR shaving forums peddling that crapLast edited by gssixgun; 04-29-2021 at 04:13 PM.

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

04-29-2021, 04:02 PM #64At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,030

- Blog Entries

- 1

Thanked: 13245

Damn Marty I guess we were both typing at the same time

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

04-29-2021, 05:27 PM #65Senior Member

- Join Date

- Sep 2018

- Location

- Palm Harbor Fl

- Posts

- 373

Thanked: 49

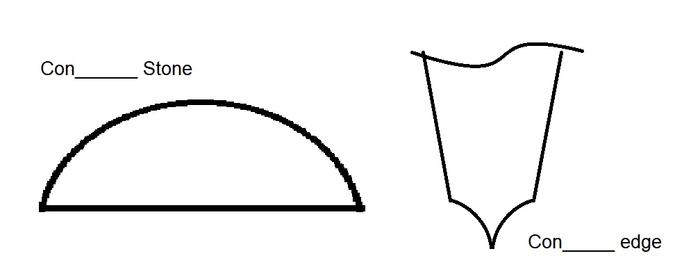

The idea was interesting at first. But theres always a latest and greatest. I think if you learn to use a convex stone(i never did) you can produce a nice edge. You can produce a nice edge with flat stones. If all we had were round cylindrical stones we would learn on those and produce a nice edge. Its a solution to a problem that doesnt exist. And for anyone to say theyre smart and everyone else is ignorant is stupid. Now the fake account pretending to be from germany? In the words of my 46th favorite president.... Cmon man! LOL

-

04-29-2021, 06:19 PM #66Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Yall all know that I don't claim to be an expert in this in any way. But what it seems like razorfranken81 is saying is that Soligen razors have always been ground and honed on a concave stone to make a convex edge. But also that the masters of the craft have all retired and are not producing the quality that they did in the glory days. It kinda seems like the argument is the level of quality degradation.

There is a small debate about the edge shape, and I certainly don't know the science of the flat, concave, and convex bevels. But I would think that with the microns we are dealing with, a fine shaving edge (at least for 99% of us) can be produced flat, concave, and convex. So here again, it seems to come back to whether or not the edge is shave ready regardless of shape. If I pulled out my first razor out of the box and it tugged, pulled, and hurt I would have thought "I guess that's why they don't use these any more" and had a fancy letter opener and a Mach III razor or stuck with the beard.If you're wondering I'm probably being sarcastic.

-

04-29-2021, 06:41 PM #67At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,030

- Blog Entries

- 1

Thanked: 13245

Last edited by gssixgun; 04-29-2021 at 06:45 PM.

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

04-29-2021, 06:58 PM #68Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

See, I clearly don't know how concave and convex is defined. After reading so many of these I am not entirely sure there is agreement.

I totally understand the commercial aspect of the plates/stones/etc. Which is why I find it interesting, but for my face will use flatish stones that start to dip in the middle with use until I can't get a comfy edge and flatten it again.If you're wondering I'm probably being sarcastic.

-

04-29-2021, 07:00 PM #69Senior Member

- Join Date

- Sep 2018

- Location

- Palm Harbor Fl

- Posts

- 373

Thanked: 49

-

04-29-2021, 07:16 PM #70At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,030

- Blog Entries

- 1

Thanked: 13245 "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

327Likes

327Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote