Results 81 to 90 of 281

-

03-19-2023, 06:20 PM #81

Ruining an edge isn't the same as ruining a razor, and there are degrees of ruining the edge, from minor to kind of major. If you want to refresh Paul's edge in a low impact, low risk way, consider this. Get yourself three pieces of inch thick acrylic, 3" x 12", and a 36" piece, or three 12" pieces, of 1/4" thick by 3" wide balsa.

Glue a 12" piece of balsa to each 12" long acrylic plate. End result, three balsa planks stabilized with inch thick acrylic, light but thick enough to use in hand.

Next, now that the balsa is stabilized and can't flex or warp significantly, stick a sheet of 220 grit sandpaper to a very flat surface. Ideally this would be a granite surface plate but if you use a sink cutout from a granite countertop (usually free, if you are in the right place at the right time and ask nicely!) you will never know the difference. A polished marble floor tile, 12x12, will work. I use an 18" long acrylic plate. I get all my acrylic from TAP Plastics. I use 4" wide roll sandpaper for this. The 18" long stroke length avoids overruns.

Anyway stick your sandpaper with a light spritz of 3M, LocTite, or other spray adhesive to your plate, being carefull to keep it stretched and not allow air bubbles or foreign matter to get underneath it. That is what you will use to lap the balsa.

Lap the balsa. Don't use the pencil grid method, it makes dents in the balsa. You can see the surface texture change, that's good enough. Periodically while lapping you will have to stop and unload the sandpaper with a bronze bristle brush or even a toothbrush will work, because it will load up fast. After you lap the balsas with the 220, repeat with 320 or 400. Wipe off all dust.

Apply a VERY SMALL AMOUNT of diamond paste. Not enough to cover it. About 2/3 of a pea size lump is more than enough. Dot it around best you can, then rub with the palm of your hand. You want to rub it in to the balsa. You want those diamonds buried deep in the grain and barely sticking up. Rub rub rub. Do the finest one first, so you never contaminate the finer grit with traces of a coarser grit. When you are done, it should seem like you don't even have half enough. Believe it or not, you got too much. Rub down the balsa with al old tshirt to pick off the excess. You must not have a coating! It must all be embedded in the balsa. You want three grits, .5µ, .25µ, and .1µ. If the edge is pretty far gone, you could start with 1µ only to avoid having to hit a stone, though normally I recommend going straight from 12k stone or 1µ lapping film, to the .5µ balsa.

Now, we call this a balsa strop, though technically it is a hone. It's object is to remove submicroscopic amounts of steel, not to straighten or align the edge. But people still call it a balsa strop, and still call using it, stropping. You may think of it that way, as you use it. Do round trip x stroke laps, spine leading, just the same as if you were stropping on an actual strop. Keep the spine on the balsa. Hold it in hand. In hand. Repeat, in hand. Don't lay it on your workbench. Using it in hand helps to regulate pressure and alignment, and if a slight roll is needed because you have a bit of smile in the edge, it takes care of itself. Use roughly the weight of the razor, and go 50 or 100 laps. Wipe the blade and wash your hands, and have a go on the .25µ. Next, of course, the .1µ. About every 5th or 10th lap, interject with a pair of what I call pull strokes. To do a pull stroke, lay your razor on the balsa but instead of stroking it toward the end, pull it straight sideways about 3/4" or so. That's all. This helps to strip artifacts from the edge and keep it clear. Do one side then flip the blade over and do the other side. One stroke each side, that's a pull stroke lap. When finishing up the final stage, finish with an additional 20 or so very short x stroke laps. Pretend your balsa is only 4" long and you will have the idea.

If the edge is not super super sharp and smooth, do the whole process again. Strop on your hanging strop, and have a shave. Keep the shave angle low or you will filet your face, if you nailed in on the first attempt. If you do this right, starting with a good edge, (normal slight dullness from normal use is okay) you should end up with the same level of sharpness and cutting ability as my razor in my shave video. Actually, maybe better, due to the tighter bevel angle of the Dovo.

From that point, you can maintain your edge indefinitely with 50 extremely light laps with only the .1µ balsa, after every shave. I never have to re-hone my razors, ever.

A trick for getting ultralight pressure is hold the balsa vertically, so the full weight of the razor does not bear down on it. It's just a brush worth of pressure. More laps, less pressure. That's the key here.

Total cost is significantly less than what you would pay for a good 12k stone, and gives you a much sharper "refreshed" edge. This method does not remove enough steel to make a dull edge sharp. It works well in making a reasonable sharp edge extremely sharp.

Later on, when honing your own razors from scratch, you STILL don't need the 12k finisher, necessarily. You can use another acrylic plate and 1/3 of a sheet of lapping film, 1µ grit, preferably 3M type 261x or 262x, plain back, no adhesive. Alternately, NanoLapTech type 26M. Not generic BS like what is all over amazon or fleabay. I find that 1µ lapping film is the perfect jumping off point for the balsa progression.

Will other stuff work, like CrOx and FeOx? Yeah, sort of. Depends on how high or low your standards of excellence are, what you are willing to settle for.

Longstanding members of this or indeed pretty much any online straight razor forum who present themselves as being able to hone, are going to know what they are talki ng about. They might well argue finer points or even major ones. That's okay. Pick one. Eeny, Meanie, Miney, Moe, works about as good as anything. I will cheerfully tell you that my way is the best way. Somebody else will shout me down and call BS. Guess what? Either way, you are getting a tried and true method with a proven track record. Just pick one. I'll make it easy for you. Don't use my method.

There. I made things a little more simple for you, and you will still succeed if you can stick with one set of instructions. If someone is not an established member of a forum or is not well known and widely respected on one or more forums, his self promotion might well be "internet talk".

Don't worry about arguing or guys contradicting one another. It is CSLD, or Chicken Stuff Little Details. There is no established "honemeister" on this board who will give you a useless excuse for a shave ready edge.

50 hours? It took me closer to 50 months, just to start getting good shaves with my razors. Of course that was before Al Gore invented the internet. <insert your favorite smiley here.> I had no mentor, no books, no videos. I started out with a wonky Dovo Best and the stones I sharpened my work knives, pocketknives, and kitchen knives on. A belt for a strop. Lots of strikes against me there. The road was rough and I stuck it out. I always looked like I had spent the morning sorting wildcats or doing dermabrasion with poison ivy. You have a trememdous advantage, in having plenty of material to read and watch, and easy availability of truly marvelous tools and materials from around the world. Still, if you try to chart your own path, you shouldn't be too disappointed if it takes a lot longer than 50 hours! I think 50 weeks is probably more typical, and 50 days is pretty good.

Okely dokely. But I do think until you are ready to commit completely to a particular method and tool set, you are better off letting Paul have a go at it. He can tell you almost immediately if it is a good razor or not, and you already know what you can expect from his edge. And just for return shipping? Very generous. Take him up on that offer. Then when you get it back, use it, strop it, and when it starts to get dull, learn how to touch up the edge with your chosen finisher and finishing method. That is your gateway drug into honing. You will do probably 20 touchups for every "from scratch" honing. Nail the finish on a razor previously shave ready. THEN work on setting bevels and running a full progression.

Okay I'm gonna butt out of this thread now. Good luck!

-

03-19-2023, 09:15 PM #82

50 hours over the course of longer than 50 months, quite likely

I certainly don't expect to me good at it 2 days from now. If it took 50 months of daily practice I wouldn't think twice about getting rid of these razors,.

I certainly don't expect to me good at it 2 days from now. If it took 50 months of daily practice I wouldn't think twice about getting rid of these razors,.

I did just try to shave with Paul's razor, same problem as my Dovo, seems kind of obviously dull after a while, but I still got a full face shave out of it with a strop mid-way through. I think I'm going to have to study stropping technique more, I feel confident I'm doing it wrong. Or maybe it just leads a light touchup on the 8k.

I'm going to go without any sort of finishing stone for a while. if 1k, 4k, 8k, paste strop, linen strop, and leather strop aren't enough to get a decent shave, I'm not interested. From what I hear this should be more than enough.

-

03-19-2023, 09:18 PM #83

Thanks for posting your balsa honing info CCR. Interesting reading.

- Mick.

-

03-19-2023, 11:48 PM #84

No sweat. A bunch of us on another forum hammered that method together over several years. It is how I post-finish and maintain all my razors. When you combine that with good quality lapping film (or alternately, the Naniwa SuperStones 1k to 12k) and a bevel setting system, you get what we call "The Method" and it works a treat. I have been meaning to do a detailed write-up on this forum but things get in the way. Now that I am retired, I don't get days off anymore.

-

03-20-2023, 12:04 AM #85

0.1 micron is something like 253k grit, dear lord. My razor feels like it's maybe sharp up to 4k.

-

03-20-2023, 02:35 AM #86

Look, I know there is a lot of information and some of it seems to contradict. As said, there are many different methods, as many as there are honers. Most have their own methods and get to the same place in the end. Some, especially on YouTube (no offense to anyone qualified among the numbskulls) are morons. I think one thing that plagues you is that honing a razor seems like any idiot should be able to do it off the cuff. The reality is that it is more complicated than it seems. You are obviously a smart young guy and that can be frustrating. It has frustrated many of us in the beginning.

I think what would help you most of all is some in person or Skype or zoom. I have made that offer. I'm sure others would do so also. It's not all that complicated. Find someone who you believe in and make them your Sensei.Last edited by PaulFLUS; 03-20-2023 at 12:16 PM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-20-2023, 02:12 PM #87

Yes, I was not referring to anyone on these forums when I mean people who sound like they don't know what they're doing, on youtube there is all these guys who make up fake sounding terminology, and approach metal sharpening like they are doing an exorcism of a razor, it's just plain goofy. Also to be clear, I'm not using these youtube goofs as an excuse to not put the effort into learn, I was simply expressing my frustration with them, when I have time I'll do a lot of reading and watching. I'm really not frustrated by it being difficult, I'm not expecting to be good at it right away, I think it would probably take minimum 20 honings to start to see a decent edge, I am fully okay with this. I'll do a deep dive into the literature on this forum for honing techniques soon, I just have been very busy lately. I may see if there is anyone on here who sometimes visits my city and just book a future lesson in person, or if that's not possible just go back to zoom.

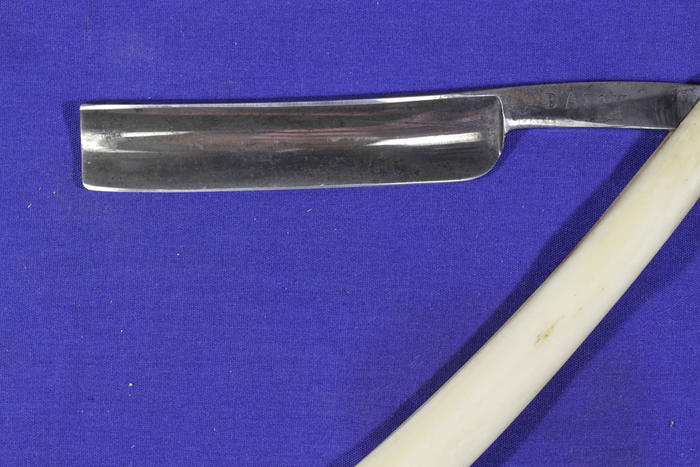

Here is the Daisy razor I was speaking about practicing on:

I think this should be more than adequate. There doesn't seem to be any obvious issues with steel quality, geometry, damage, wear and tear, etc.

-

03-20-2023, 02:17 PM #88

I'm confused why people keep assuming I have an arrogant attitude towards learning this. Maybe it's just because I make fun of some youtube goofs.

I've already failed miserably multiple times at honing a razor, I have no illusions about being a natural at it or expecting it to be easy. I'm still here, I still want to learn. I understand that the masters here are currently much better at it than I will likely ever be.

-

03-20-2023, 02:57 PM #89

Your doing fine.! Don't underestimate yourself, or you've already failed.

Even I, after decades of honing can be humbled by getting a bevel set on one, occasionally.

Time and patience, keep at it, it'll come together for ya. There's no shortcuts in honing.Mike

-

03-20-2023, 09:06 PM #90

It’s just practice, wax on, wax off. You’ll get there if you practice enough. Keep on keepin’ on!

My doorstop is a Nakayama

333Likes

333Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote