Results 41 to 50 of 51

Thread: Tamahagane with other kanji???

-

10-27-2013, 11:13 PM #41

I'd say that's a distinct possibility Mike yet I'm surprised that even a partial grind would curve like that. Atypical of what I would expect from a Japanese forge. You see plenty like that on eBay & I've always just thought they were worn or abused. If the top of the Ura had that much wear at the start you could say it was from a lot of honing otherwise yep hard to say for sure.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

10-28-2013, 07:41 AM #42

-

10-28-2013, 03:18 PM #43"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

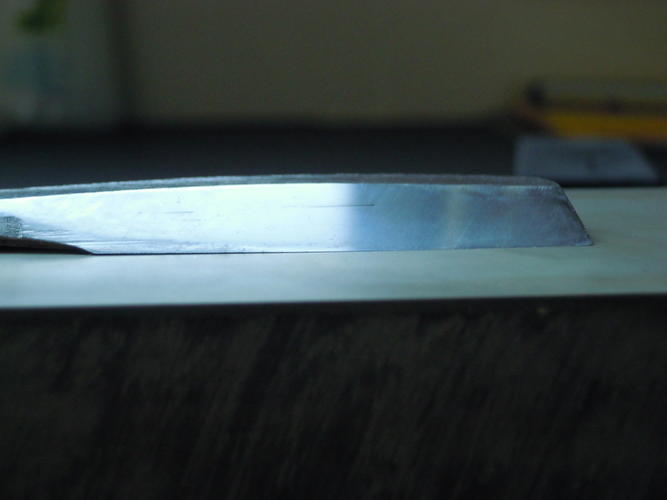

With those new pictures, the omote grind looks straight. From this grinder's perspective, I wonder that grinding the Ura exposed the flaws we can see and the next step would have been to see if it could be ground down to find out if there was a bottom to the flaw and the blade could be saved, so to speak. I think they found a few more flaws and that was the end of the effort. It also looks as if the main effort of the grinding wheel hits at an angle (not parallel to the edge) and that would explain some of the curved Ura too. More material was removed in the center trying to get past the flaws.

It's still a good piece of steel and thinking like the maker, probably more work than it's worth to try to recover from the mistakes. But that has not stopped enterprising salvagers before.

-

10-28-2013, 03:55 PM #44

-

10-28-2013, 09:00 PM #45

Thanks!

I took more pics and it seems like the entire ura is flat, but on the omote side it's a bit weird I think, the top is curved, the edge is curved when place on a really flat hone (my lovely Shoubudani), and the curved line is almost flat (at the front side a tiny bit curved, the rest is straight) when it is on the hone???

Hope the pics are more clear than my words...

Last edited by Fikira; 10-28-2013 at 09:07 PM.

-

10-29-2013, 12:23 AM #46

I see where you're coming from Mike, which is a more in depth look than I was seeing.

Very interesting how many planes are involved but I was simply referring to the contact point where the hone touches on the omote near the spine. Wasn't sure if shinogi was the right terminology ? but that is what I saw as being a difficulty in achieving a straight edge on the hones or at least creating some uneven looking bevels.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

Very interesting how many planes are involved but I was simply referring to the contact point where the hone touches on the omote near the spine. Wasn't sure if shinogi was the right terminology ? but that is what I saw as being a difficulty in achieving a straight edge on the hones or at least creating some uneven looking bevels.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

10-29-2013, 09:53 PM #47

Shinogi as in the curved ridge between the polished "fold-waves-area" and the rough carved spine? It seems to be a strange combination I guess?? The curved ridge, which is mostly flat though when laying on the hone...

If you see the last pic, there is a broad shiny polished flat area (already from the start (no much grinding left?)), but the

heel doesn't make contact (isn't polished), it bends in towards the hone, which is a contradiction I think, because the edge at the heel doesn't make contact with the hone, I had to do rolling-X moves (still the area seems not to be able to get polished, got a sharp edge though), the same story, in a lesser way, at the point...

-

10-30-2013, 01:42 AM #48

Yes that's the one. As with western razors where the edge will follow the spine these are meant to be straight on kamisori. I haven't seen any smiling kamisori newly made.

The grind also needs to be true. If the blade is warped it can be straightened because of the soft iron content unlike western razors being hard all over, tho straightening a 2" kamisori would be challenging.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

10-30-2013, 07:10 AM #49

Straightening a 2" piece of laminated steel with differential hardness would be challenging, especially considering that the part near the edge is very thin already. Perhaps you could do it with a wooden hammer and gentle tapping, but because of the shape, you cannot help but transfer a lot of force to the edge, which may not like that kind of abuse.

I'd say that you now have a working, smiling kamisori. If you start hammering, it 'might' turn into a straight kamisori, or it may turn into either a completely crooked kamisori, or 2 pieces of kamisori. Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

10-30-2013, 08:02 AM #50

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote