Results 11 to 20 of 51

Thread: Tamahagane with other kanji???

-

10-23-2013, 05:18 PM #11

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

DarthLord (10-23-2013)

-

10-23-2013, 08:26 PM #12

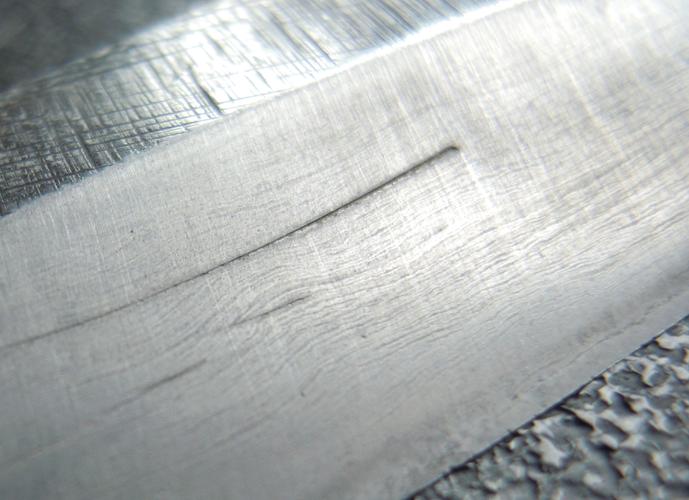

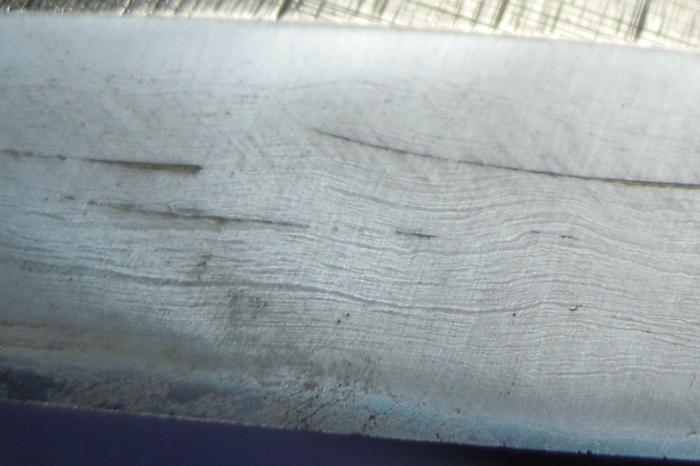

The idea of Tamahagane never came in mind in the first place, it's because I honed a layer of it, it became visible,...

The scratches, if you mean the diagonal ones, they will be cleared when finished, or do you mean other scratches?

Thank you, here are some magnifications, hope they work, the finished pics will take a few days I'm afraid...

-

10-23-2013, 08:30 PM #13

-

10-23-2013, 08:37 PM #14

-

10-23-2013, 08:44 PM #15

I believe this threat could help

http://straightrazorpalace.com/japan...amahagane.html

Kindest regards

-

The Following User Says Thank You to Fikira For This Useful Post:

DarthLord (10-23-2013)

-

10-23-2013, 09:02 PM #16I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

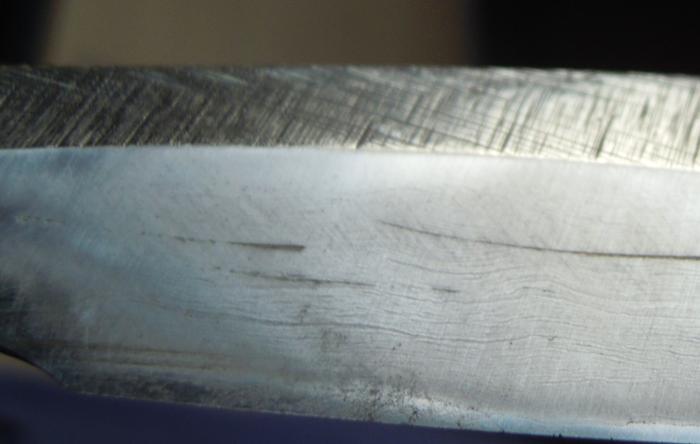

The kamisori, in the pic is showing the Omote side where the main steel is actually soft iron, that has been forged enough to form layers.

You get that kind of effect on high quality Japanese forged knives that are not made from tamahagane.

here is a very nice example of the effect:

Stefan

Stefan

-

The Following User Says Thank You to mainaman For This Useful Post:

Fikira (10-23-2013)

-

10-23-2013, 09:03 PM #17

-

The Following User Says Thank You to DarthLord For This Useful Post:

Fikira (10-23-2013)

-

10-23-2013, 09:06 PM #18

-

10-23-2013, 10:08 PM #19"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

There are several things going on that are immediately visible.

1. It is folded and welded material. No it cannot be said to be tamahagane. That is the raw smelted material. To build up a blade is orogshigane. But "-gane" means steel.

2. There is a scratch pattern from 1100 to 0500 and one from 0200 to 0800 or so. Those are scratches.

3. There is a wave pattern running from 0900 to 0300 that represents the folded material.

4. There could be cracks in the steel. One of the short odd lines runs across all the other patterns from west to east or vice versa.

4a. There are a couple of the longer ones that could be inclusions/flaws between welds/folds. If they are they are non fatal flaws because they don't cross the edge. They aren't pretty but not fatal.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Fikira (10-24-2013)

-

10-23-2013, 10:12 PM #20At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,069

- Blog Entries

- 1

Thanked: 13249

-

The Following User Says Thank You to gssixgun For This Useful Post:

Fikira (10-24-2013)

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote