Results 11 to 20 of 149

-

07-16-2013, 04:57 PM #11

Thanks!

Thanks!

Thanks for this post Neil. You are a wealth of information...and a valuable asset to this site!

Having read your post, I now believe that the working edge of this little tool is probably some form of lead containing pewter. The Patent mark in the side of the 'Strop-Aide' shows a Date of Aug. 4, 1906.

Perhaps ( and this is pure conjecture on my part ) the Griffon Cutlery Co. starting manufacturing/distributing these 'tools' based in part on the information from these publications that you have referenced? The dates certainly seem to coincide with the Patent Date...

It is an interesting bit of history about our hobby, and now I am glad I was lucky enough to find this little 'piece of history'!

Next step for me (since at my age I'm not too worried about Lead Poisoning ... ) is to grab a strop, follow the instructions you've posted above, and see what happens. I have a perfect older but very serviceable Illinois model 127 leather and linen combo strop and a razor that is due for a touch up on the hone that I can use for my 'experiment'.

) is to grab a strop, follow the instructions you've posted above, and see what happens. I have a perfect older but very serviceable Illinois model 127 leather and linen combo strop and a razor that is due for a touch up on the hone that I can use for my 'experiment'.

I am actually kind of excited about it now...

I knew you would have the answer...

Thanks

WP34

-

07-17-2013, 07:05 PM #12

Additional Information:

I just found and interesting Quote from "Essay on Barber's Razors, Razor Hones, Razor Strops, and Razor Honing (1895)" :

“Once in A week or ten days scrape the strops lightly with the back of the shears and rub on lead pipe or rub-stick, and rub the hand over it before stropping.”

So it would appear as Neil has noted in a post above that this was quite a common practice: i.e. using a lead or lead compound on your stop.

-

07-17-2013, 07:30 PM #13aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Just wipe the razor with a soft cloth after stropping and you should be good.

Edit: if worried about the lead contamination on your face.Last edited by ScottGoodman; 07-18-2013 at 01:19 AM.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

07-17-2013, 09:47 PM #14

-

07-17-2013, 10:40 PM #15

That's a real beauty Geezer! Thanks for posting that pic. I have a absolute NOS American Hone Co. combination Strop and Hone with attachment for safety blades (NOS as in never been touched at all including the instructions and box) that is literally factory new. I will dig it out and snap a few pics.

I just love this old stuff!

WP34

-

07-23-2013, 01:16 PM #16Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

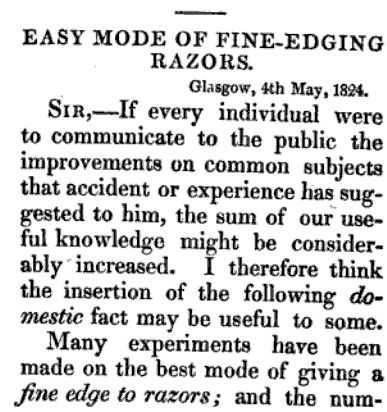

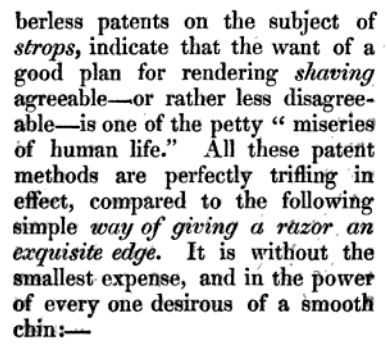

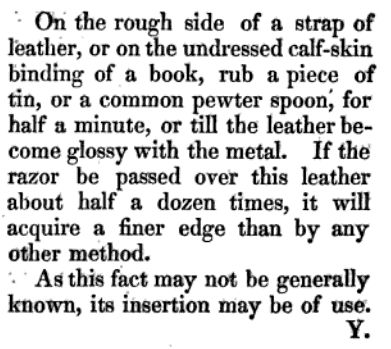

Another example of using Tin or Pewter on strops from 1824.

-

The Following 4 Users Say Thank You to Martin103 For This Useful Post:

Geezer (07-23-2013), ischiapp (08-01-2013), Neil Miller (07-23-2013), Steel (09-26-2016)

-

07-23-2013, 02:34 PM #17

Great post that!

We would be applying lead oxide or tin oxide to the strop, or both in the case of pewter. I have often seen graphite recommended also.

-

07-23-2013, 02:41 PM #18Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

All very interesting but if it works,how/why do's it work?

-

07-23-2013, 02:58 PM #19

Good question!

Tin oxide is commonly sold as a rock polish for tumblers.

Graphite is a slow speed lubricant.

Carbon may often be a abrasive in the form of Carbon black (also known as acetylene black, channel black, furnace black, lamp black or thermal black) each of which have a different amount od cutting power.

A site with a lot more information:

Abrasive Grain / Grit / Powder, Inorganic, from READE

~Richard

-

-

07-23-2013, 03:17 PM #20Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Good info Richard.

Lead also has some lubricating Qualitys,Wonder if thats part of the equation?

326Likes

326Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote