Results 21 to 30 of 149

-

07-23-2013, 03:21 PM #21

Well, old pewter is a combination of mostly tin and other metals including lead:

https://en.wikipedia.org/wiki/Pewter

~Rihcard

PS. Now to get some work done! SeeYa

-

07-23-2013, 03:22 PM #22

Interesting how getting a good or even a shavable edge is a never ending topic of discussion for all SR users of any era.

It appears to me to be another form of "pasted" strop. Was the device intended for use on an every day strop? JR Torrey sold and advocated the use of their strop paste and attributed their claimed superior strop performance to the treatment on their strop leather.

Lead is hazardous to adults as well as children. People often get poisoned from eating, drinking, or smoking after handling lead dusted or lead objects. I would wash my hands carefully after handling a lead treated strop as well as clean my razor before use.Last edited by sheajohnw; 07-23-2013 at 03:26 PM.

-

07-23-2013, 03:55 PM #23Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

As far as I can make out, the main thing contributing to the razors edge was lead. Old pewter came in three grades, each grade containing from 78 - 95% tin plus traces of antimony, zinc, etc. 'First grade' was used for tableware, so had to be harder - adding lead would have meant adding ductility, so copper (a very small percentage - around 1%) was used. 'Second grade' was for cups, and so on and was made with 1% copper and 4% lead. The ordinary or 'lay' pewter ('third grade')- the softest available - had 15% or even slightly more lead in it.

Most of the articles that mention pewter say to use the softest available, ie, the one with the most lead in it.

Others mentioned above promote the use of just plain lead. So lead is the common denominator.

Left on its own, lead tarnishes, first forming lead oxides, then lead carbonates then lead sulphides - after a while these form the dark grey patination on the surface of lead (the white powder carbonate excluded).

After theorising that litharge (a slippery form of lead oxide, usualy dark grey it can also be red or yellow) could evolve from rubbing the strop with a bar of lead, I now have to discount the idea because you need to heat lead to 600 degrees C to form litharge! Lead sulphide is soft and can reduce friction, so this might be a candidate, acting in much the same way as graphite does (I have dusted finishing strops with micro-fine graphite powder and it is very good). Lead carbonate (white lead) is also a type of lubricant.

So, using a lead bar could conceivably:

a. flatten the strop,

b. fill any shallow depressions,

c. reduce the draw.

All the above seem a little speculative though. What is not speculative is the almost universal use of the 'lead lap' in Sheffield at one time in finishing the finest razors and cutlery items. It gave an unsurpassed polish. Although polishing materials remove incredibly small amounts of metal that is how they work - removing metal. If I had to choose I would go for this option, as the formation of the oxides, carbonates and sulphides mentioned above all depend on exposure to the elements, especially rainwater.

Regards,

NeilLast edited by Neil Miller; 07-23-2013 at 04:03 PM.

-

-

07-23-2013, 04:02 PM #24Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Just do not understand how you can remove ferrous metal with non-ferrous metal.

-

07-23-2013, 04:06 PM #25Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I have no idea either. But it is well documented that elements much lower on the MOHS scale than steel when used in powder form leave a more refined (ie sharper) edge than just using an ordinary leather strop. Black magic, if you ask me.

Even graphite dusted strops give a more polished bevel. Polishing means getting rid of very fine scratches. How are scratches removed - by removing metal.

Regards,

NeilLast edited by Neil Miller; 07-23-2013 at 04:08 PM.

-

07-23-2013, 04:24 PM #26Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

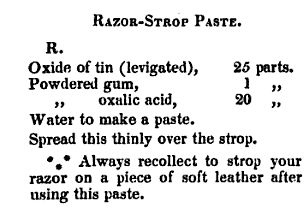

I believed the residue left by the pewter or lead, acts like a pasted strop, even came across an old recipe for pasted strop with tin from 1841.

-

07-23-2013, 04:29 PM #27Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

As eluded to several times above,I think it is what the lead turns into as it oxidizes,forms an abrasive media of some sort,maybe

-

07-23-2013, 04:35 PM #28

Thanks all for the great posts (especially for that article from 1824 Martin!)...

So...I tried an experiment with the Strop Aide this morning. A 3 day beard (figured a tougher beard would be a better indication of performance) with a Jacques Lecoultre Au Sentier. A vastly underrated shaver by a lot of folks I think...at least based on the prices that they regularly go for on the Bay.

An old but nice Illinois linen strop: The one all the way to the left of the picture...

The blade was just about ready for a few quick round trips on the hone so I figured I would give it a try to see if the Strop Aide improved the shave.

I stropped as normal: 20 or so laps on the canvass-60 or so on the leather and proceeded to shave one side of my face. Passable but still a little 'Tuggy'...

Then I Applied the Strop Aide to the linen until the linen had a greyish hue to it. Stropped the razor about 50-60 laps. Re-stropped on the leather for 100 laps and proceeded to shave the other side of my face.

The results....Much, much smoother and also seemingly considerably sharper. No tugging whatsoever! A very nice, abrasion free shave.

My conclusion is that it made quite a difference...although I have to be honest enough to admit that maybe I just 'wanted it to be better' and the extra laps on both linen and leather were what improved the edge. I do know this though...I will continue to use this blade for awhile using the Strop Aide each time to see how long the edge remains sharp and smooth without going to the hone or pasted strop.

My recommendation...

Give it a try with a lead pipe or piece of old pewter if you have something handy, and a blade that needs a little improvement.. I would be interested if anyone else experienced similar results.

WP34

-

The Following 4 Users Say Thank You to Wolfpack34 For This Useful Post:

Geezer (07-23-2013), Martin103 (07-23-2013), Neil Miller (07-23-2013), sharptonn (11-04-2015)

-

07-23-2013, 05:33 PM #29

-

The Following 2 Users Say Thank You to Lemur For This Useful Post:

Martin103 (07-23-2013), Wolfpack34 (08-01-2013)

-

08-01-2013, 04:42 PM #30

UPDATE...Lead Oxide Particle Properties:

UPDATE...Lead Oxide Particle Properties:

After doing a little more research I found this article:

8. Harvey E. Brown, Lead Oxide. Properties and Applications, International Lead Zinc Research Organization, Inc. 1985

The pertinent information I was able to glean from it is that...

"The median particle diameter is from 0.50 to 1.0 microns, as compared with 3.0 to 16.0 microns for lead

monoxide manufactured by other methods."

So..it would seem that lead oxide has a particle rating of somewhere around the same level as Chrome Oxide. I found this quite interesting, and it helps explain (to me anyway) the reason why this "Strop Aide' seems to work so well.

More subjectively...I have now tried this 'lead strop' treatment on all of my shavers for the past few days, and I have found it to be extremely effective in giving all of my 'edges' that smoothness that I like to call 'Sheffield Smooth'...IYKWIM.

I would recommend this to anyone, and would like to hear of others results.

WP34

326Likes

326Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote