Results 20,551 to 20,560 of 20573

Thread: What are you working on?

-

08-10-2024, 01:04 AM #20551

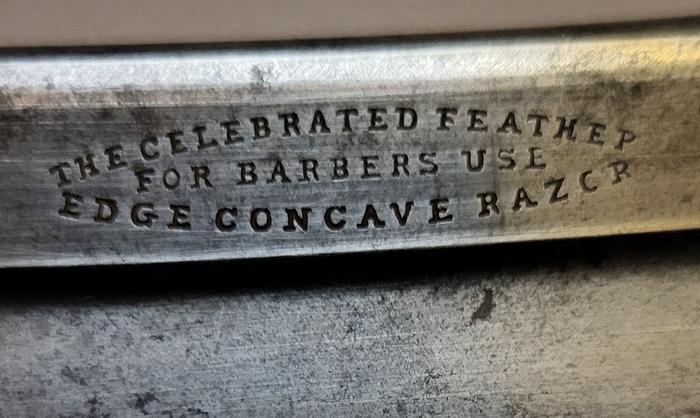

I got this blade in a lot from an auction. It is pretty badass except for the obvious big chips.

It's 8/8+, 17/16 to be exact. Here's a close up of the spine stamp.

I've never seen another one stamped the same.

I have toyed around with differnt methods of taking those chips out. I have considered giving the whole blade a taper, bringing the heel forward or giving it more curve or a combination of both...or all three. I was thinking maybe something like this.

I'm stoked about this one because...as stated, it's badass, but, that being the case I don't want to start grinding and say, "Why did I do that?" The one thing I've learned though is when in doubt, wait it out.Last edited by PaulFLUS; 08-10-2024 at 01:09 AM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

08-10-2024, 01:17 AM #20552Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

I’m not sure I’d jump straight to moving the heel forward but you will need to move it some for the shape to flow. High angle honing and just go slow until the forward chip starts to make sense and see how little you can take from the back to get that back chip straightened out.

It's not what you know, it's who you take fishing!

-

08-10-2024, 04:29 AM #20553Aristocratic treasure hunter

- Join Date

- Nov 2013

- Location

- Saint Marcellin, France

- Posts

- 420

Thanked: 154

I always feel that on these old blades less is more, and the more peculiar they are, the less you should touch them.

I absolutely love this oneBeautiful is important, but when all is said and done, you will always be faithful to a good shaver while a bad one may detter you from ever trying again. Judge with your skin, not your eyes.

-

08-22-2024, 12:25 PM #20554

Finally got this one done. It's been in the restoration in progress drawer for a coon's age.

Henry Sears & Son #640, "Queen 3/4" NOT 6/8

I've been shaving with it's big brother exclusively for the last month and a half with an old edge which needs no help. The 7/8 is probably my best shaver of all. This one was a bit of a problem child. It was a microchipper. I wanted to do a full Ark progression but quickly realized that would not work so I down-shifted to the softer stones and at finish gave it a microbevel to stabilize the apex. It shaves well, just not the WOW shave of the bigger one, who now...

...has a mini me!!!Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

08-22-2024, 07:22 PM #20555

That is truly outstanding Paul!

Semper Fi !

John

-

The Following User Says Thank You to Johntoad57 For This Useful Post:

PaulFLUS (08-22-2024)

-

08-27-2024, 02:32 AM #20556

Here's another one that has been in the drawer for far too long. Joseph Wostenholm & Sons *EBRO*

Before:

I swore I had some individual and more in progress pics but this was what I could find.

Got some more sanding done on the blade.

That top pic doesn't capture the extent of how pitted and cruddy it was. The scales need a lot of work too. More on that later.Last edited by PaulFLUS; 08-27-2024 at 02:55 AM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

08-27-2024, 03:27 PM #20557

What are you going to do with that big ass hole in the tang?

Semper Fi !

John

-

08-27-2024, 05:38 PM #20558Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,317

Thanked: 3228

-

08-27-2024, 06:01 PM #20559Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

I’ve had good luck just pinning them the way they are. The holes usually look worse than they are. They tend to taper in to the middles. I royally messed up the one I tried to drill and sleeve. That hole needs to be dead straight. I wound up filling it with JB Weld and trying two more times.

It's not what you know, it's who you take fishing!

-

08-27-2024, 07:51 PM #20560

Same here. I tried all that. Seems to do nothing or cause issues at times. I don't use spacers on them either. The big, funky hole seems to allow the tang to slide as necessary when opening and closing, seems to keep the blade centered in the scales better.

IF the scales are straight!"Don't be stubborn. You are missing out."

I rest my case.

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote