Results 231 to 240 of 20602

Thread: What are you working on?

-

03-23-2014, 09:44 PM #231

hes I know the grit was a bit fine but I thought I already had some 180 that I intended to use but as it was about 7pm when I started & realised I only had the 220 as my coarsest grit, my impatience with myself just said suck it up & see how far we get for the night.

but i now have some 120 & 180 to go before the 220 for the blade face to make it easier and quickerLast edited by Substance; 03-23-2014 at 09:49 PM.

Saved,

to shave another day.

-

03-23-2014, 11:37 PM #232

Started grinding my gold dollar special today... so hard to go slow. I just want to go go go!

-

03-24-2014, 05:22 AM #233aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

-

03-24-2014, 04:02 PM #234Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

One in 5160 one in 52100. The one in 5160 is 1/4 inch thick at the spine and slightly hollow in the middle of the blade so that veggies will slide off easily.

They're currently tempered and ready for final grinding.

![Name: photo 2[1].jpg

Views: 419

Size: 28.0 KB](https://sharprazorpalace.com/attachments/workshop/160777d1395676373-what-you-working-photo-2-1-.jpg)

![Name: photo 1[1].jpg

Views: 416

Size: 40.7 KB](https://sharprazorpalace.com/attachments/workshop/160778d1395676424-what-you-working-photo-1-1-.jpg)

A friend came over this weekend and I guided him through the process of making a knife. We got it HT'ed. It's a drop-point hunter. It's got forge scale on it in this pic.

Let me know if you need any help with shaving, honing, etc.

Let me know if you need any help with shaving, honing, etc.

-

03-25-2014, 09:33 PM #235

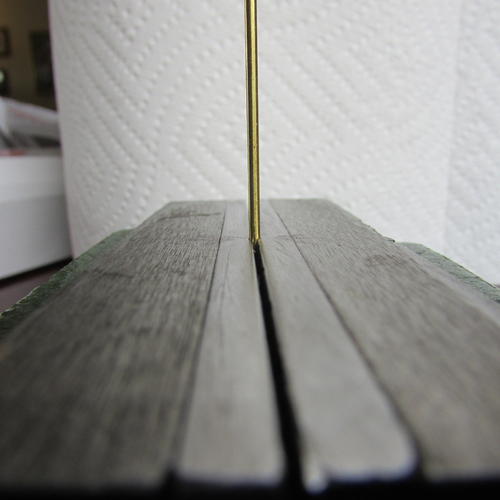

I'm embarrassed to even post what my latest project is!! But I find that function over form will always prevail!!

I've struggled with keeping the 1/16" brass rod 'straight' while in the small vice that I use. (I live in an apartment)!

SO!!! Here's my solution!

I smoothed up the faces of the removable plates so that they were more close to being square and aligned and then I installed some card stock when I closed the vice. I then used my small drill press and a 1/16" drill to drill a hole between the plates. The card stock 'spacer' made the 'hole' slightly smaller so the jaws could now firmly hold the rod secure and straight! Well as close to 90 deg's as my setup would allow!

Ya Just Can't Keep An Old Redneck Boy Down!

Last edited by cudarunner; 03-25-2014 at 11:09 PM.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

-

03-25-2014, 09:37 PM #236No that's not me in the picture

- Join Date

- May 2013

- Location

- Los Angeles South Bay

- Posts

- 1,340

Thanked: 284

Thanks for the post, I have the exact same issue in my vice and suspect that's why my latest rescale doesn't close on center.

You've now motivated me to fix this once and for all. I love the card stock idea to get the right size hole.

Now I just have to see how well they hardened the jaws I love living in the past...

I love living in the past...

-

03-25-2014, 09:44 PM #237

-

03-25-2014, 11:11 PM #238

-

03-26-2014, 12:51 AM #239

Cuda sorry I can't relate with this level of potential OCD as I only have & use a pair of vise Grips for holding the my pin rods in a slot in the side of my wood bench top,

I think you would freak out at this looking at you set up but after & re-sand the grip lines of the pins it seams fine LOL Saved,

Saved,

to shave another day.

-

03-27-2014, 08:16 PM #240

Just did some heat treatment on 3 new razorblades in O1 steel. They are now tempering to 60-62 HRC

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote