Results 351 to 360 of 20600

Thread: What are you working on?

-

06-22-2014, 11:16 PM #351

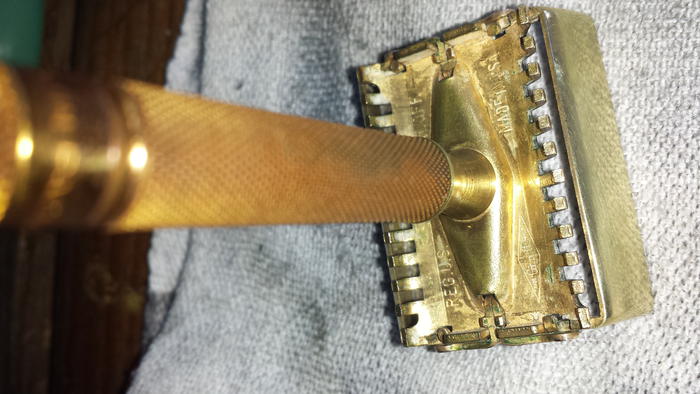

I'm almost done cleaning up a Gillette safety razor I found in an antique store. I know nothing about it though so I need a little help IDing it.

Last edited by gkofsky; 06-22-2014 at 11:20 PM.

-

06-22-2014, 11:20 PM #352

Look underneath and then maybe this will help:

RENALDO.US - Gillette Razor and Blade Dating and Feature InformationOur house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

-

06-23-2014, 11:49 AM #353

Here's a little sth I did, i posted in separated thread but sou might be interested here as well

.. Thick unstained leather case, sheath for 2 razors with a hotn plate in the middle section for better protection..

.. Thick unstained leather case, sheath for 2 razors with a hotn plate in the middle section for better protection..

…finished, closed

..opened

..side view with 2 razors

-

06-25-2014, 09:50 PM #354

I just glued the knots to this puppies; 30mm and 28mn respectively.

-

06-29-2014, 02:34 AM #355I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

I'm making this one into a classic Barber style brush handle. One I saw on the thread Bongo posted, with old posters that had pics of brushes available back in the day.

The wood is African blackwood and Golden Amboyna burl. This one will be staying with the old school feel and getting a big old Boar knot.Burls, Girls, and all things that Swirl....

-

06-29-2014, 03:13 AM #356Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

06-29-2014, 03:35 AM #357I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Not quite done the finish. Pure Carnauba is a PITA!! But I'm liking how it looks.

I'll post some better pics tomorrow when the suns out. my pics suck without the sun.Last edited by HARRYWALLY; 06-29-2014 at 03:41 AM.

Burls, Girls, and all things that Swirl....

-

06-29-2014, 04:13 AM #358Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

That looks great,super design,only issue I have ever had with pure Carnuba is it waterspots big time

CAUTION

Dangerous within 1 Mile

-

The Following User Says Thank You to pixelfixed For This Useful Post:

HARRYWALLY (06-29-2014)

-

06-29-2014, 04:31 AM #359I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Yup, I read one of your posts about that. A couple coats of ren wax should take care of it.

Burls, Girls, and all things that Swirl....

-

06-29-2014, 05:32 AM #360

I'm building a workshop for restoring razors. The main machines are a buffer, a belt sander, a drill press, and a scroll saw. The workshop is being embedded inside a laundry room that doubles as a storage area and also has bookshelves along the walls.

The buffer is on a stand on the worktable:

When it's in use, the buffer will be pulled forward and clamped to the work table:

The other three machines are behind the work table, on shelves that used to hold books. I moved the books and raised and lowered shelves as needed to get the machines at a good height for working:

Today, the scroll saw got placed. To make room for it, I had to cut out a chunk of the drywall to use the six inches of space between that wall and the wall of the adjoining room:

Only two big chores still to go. Space is very limited, but the ceiling is high, about nine feet, and it is unfinished. Floor joists from the room above are exposed. So I'm going to suspend two platforms from the floor joists, one platform for a dust collector, and the other for a 20-inch square fan with a dust filter attached to the back. The platform for the fan will also provide a plank on which to clamp work lights directly over the work table.

The platform for the fan and lights will go inside the buffing area. Four polyethylene sheets form a plastic room in which to contain the buffing dust. The polyethylene sheets are on rollers so that they can be rolled up out of the way when they are not being used. When they are rolled down, the sides of each sheet attach to the adjoining sheets with vertical strips of Velcro:

The dust collector will go outside the buffing area and will have a hose inserted through the polyethylene and connected to a box behind the buffer. If all goes according to plan, most of the remaining dust will be caught by the filter attached to the back of the fan.

I started on this building project three months ago, building the work table and the shelves standing to the right of the work table. Kept getting in deeper, spending more time and money than I had originally anticipated. I can see light at the end of the tunnel now. It will be nice actually to use all this equipment. I've restored a couple of razors with hand-sanding, just to ease off the frustration of waiting until I could get all the equipment in place.

Joe

91543Likes

91543Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote