Results 391 to 400 of 20602

Thread: What are you working on?

-

07-08-2014, 04:19 PM #391

Bruno, I like the last one with the hammer strikes. But, as always, I really like them all. I have a razor that I was able to salvage with sorghum molasses but the rust on the tang left divots like the forged razor, I like the way it looks and shaves.

-

The Following User Says Thank You to guitstik For This Useful Post:

Bruno (07-09-2014)

-

07-12-2014, 10:46 PM #392

3 more I heat treated today. I also forged another hammer finish razor and finish forged 2 blanks. I only post pics of the HTed pieces. They all get HTed sooner or later, and otherwise I have to spend a lot more time taking pics.

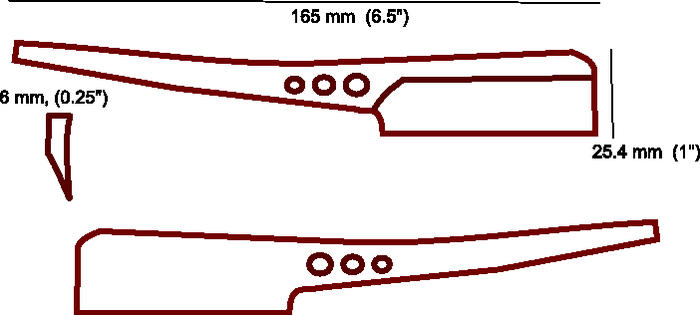

The first and third one were handforged. The first one was styled after an ottoman. The second and 3d are my own design. The second one was asked to be a 6/8, classical style but with a holed paddle. I decided to combine classic joseph rodgers with modern attitude. The third one is a large chopper (9/8+) with a paddle. For this one I wanted to try the scalloped spine I once saw on a vintage Joseph rodgers I couldn't afford. I decided to put little circular patterns on the tang, just for the sake of not using the same jimps as the others. I'm starting to feel happy about the jimps. Still use simple files but they're coming out much more even and equally deep.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

tcrideshd (07-13-2014)

-

07-13-2014, 05:21 PM #393

cant wait to see that second one!!! keep em coming Bruno! tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

07-13-2014, 11:03 PM #394Senior Member

- Join Date

- Jul 2013

- Location

- Shreve, Ohio

- Posts

- 229

Thanked: 68

This blade has been sitting around the shopawhile so I figured it was about time to finish it and put some scales to her. 440C blade already heat treated with spalted tamarind scales and a buffalone horn spacer. Everything at this point is at about 80 grit. Blade will eventually be a mirror finish.

-

07-13-2014, 11:25 PM #395aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I have never heard of using 440c on razors, interesting. I understand it's a good steel for knives. Have you used it for razors before? Hows it hold up? How hard would you estimate it?

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

07-13-2014, 11:37 PM #396Senior Member

- Join Date

- Jul 2013

- Location

- Shreve, Ohio

- Posts

- 229

Thanked: 68

I've actually used it on quite a few and it's produced my favorite shaver. The trick with 440c is the heat treat has to be perfect. With that extra chromium and such it had a tendency to chip out if it's too hard. I try to aim for 57ish HRC if it's 60 or over its too hard

Last edited by wynndow; 07-13-2014 at 11:41 PM.

-

07-14-2014, 01:23 AM #397

I finally found a W. Greaves and Sons that I thought had some promise. I cleaned it up some and put a new set of buffalo horn scales on it. The originals were really brittle and cracked, pitted, etc... I am REALLY impressed with the edge on this razor. I re-set the edge and honed it up, and it is as sharp as anything else I have on the shelf. The heft of this thing feels really nice too. I see now why guys on here rave about the Greaves and sons.

-

07-14-2014, 03:51 AM #398Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Was going to build a brush handle tonight.not gonna happen,114Degs in my shop right now

dieing in Kali.

CAUTION

dieing in Kali.

CAUTION

Dangerous within 1 Mile

-

07-14-2014, 02:30 PM #399

Mi first straight razor, a kamosori...

Last edited by asigarza; 07-14-2014 at 02:33 PM.

-

07-18-2014, 07:35 AM #400

Fred Fenney Restore

Fred Fenney Restore

I have an old Fred Fenney blade which I had a good friend regrind for me until I get my machine up & going. The blade has a nice smile to it! I then made some scales out of some dark honey horn & it will be going together in a couple days.

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote