Results 421 to 430 of 20602

Thread: What are you working on?

-

07-27-2014, 01:41 AM #421

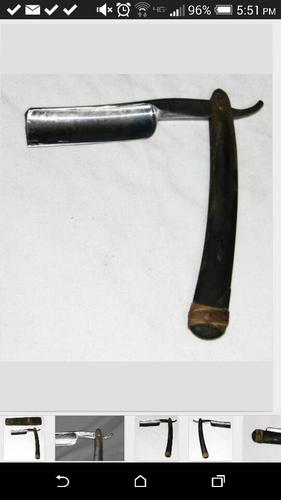

I just got this puppy

And this is how it looks now

-

07-27-2014, 01:46 AM #422

-

07-31-2014, 04:05 AM #423

I set up a buffer on a work bench and surrounded the bench with roll-up walls of polyethylene sheeting. A few days ago, I thought I was finished with building things and was ready to start learning to use the buffer. I got inside the sheeting to start using the buffer and realized I had walled myself out of easy access to buffing compound, polishers, and buffing wheels. Duh! So I built a little cart on wheels that I could roll under the work bench.

Here it is rolled out:

And here is rolled under the bench, out of the way, but providing ready access to compounds and buffing wheels:

When I'm not buffing and need to sit at the work bench, I can store the cart in a closet nearby.

The gray box behind the buffer has an outlet at the back for a hose connected to the dust collector. The dust collector is suspended on a platform above head level:

I'm working within tight limitations of space, so I've made the work area as compact as possible. Above the work bench, as part of the air filtering system, I put up a fan on a platform and attached a dust filter to the back of the fan:

I think this really is the last of the construction! I've been watching videos and reading forum postings on buffing. Just about ready to leap in, or rather, edge in, cautiously. Got a leather apron, a respirator, goggles. Taking hints from forum postings, today I also ordered a face shield and some kevlar gloves. Here's hoping I get up a good distance on the learning curve without wrecking a blade or damaging a hand.

Joe

-

The Following User Says Thank You to carrolljc For This Useful Post:

Geezer (07-31-2014)

-

07-31-2014, 04:33 AM #424

Feels good to make something doesn't it.

I'm working on learning on the buffer I built/here:

http://straightrazorpalace.com/works...-part-one.html

This what my friend PWH sent:

"Roy, take this little formula to figure your speed:

rpm of motor divided by the diameter of the pulley.

Use this as an example.

1750 rpm divided by 6" pulley=291

291rpm divided by 3" pulley = 97 rpm

A 10 inch wheel will run 97 rpm. So will a 6 inch wheel.

The surface speed is a different matter though. You might want to drop down to a smaller wheel:

A 10" wheel at 97 rpm is running 3,048 inches per minute.

A 6" wheel at 97 rpm is running 1,828 inches per minute

Formula to figure surface speeds of wheels:

10" x 3.1416 x 97 = surface inches per minute.

6" x 3.1416 x 97 = surface inches per minute".

I then contacted a friend who is a very accomplished straight razor restoration expert and he recommended going with 4" buffing wheels not only because they produced less heat BUT they would allow me to get into the tight radius that straight razors have.

Speed produces Heat and that's why I built my buffer.

I hope this helps

Last edited by cudarunner; 07-31-2014 at 05:16 AM.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

-

07-31-2014, 05:11 AM #425

-

07-31-2014, 05:20 AM #426

-

The Following User Says Thank You to cudarunner For This Useful Post:

bongo (07-31-2014)

-

07-31-2014, 05:26 AM #427

-

07-31-2014, 01:01 PM #428

It does help. Thank you! I wish I had gotten this information sooner, so that I had not stocked up on a whole lot of expensive 8" and 10" wheels

. Maybe I'll check into selling them on eBay. Meanwhile, I'll order some 4" wheels. Makes good sense.

. Maybe I'll check into selling them on eBay. Meanwhile, I'll order some 4" wheels. Makes good sense.

If anybody out there wants a good deal on 8" and 10" wheels--sewn, open, treated, and canton--do let me know.

Joe

-

07-31-2014, 06:26 PM #429

Little WIP of two pairs of scales made for a friend.

The second has to be finished. The blades are from Thiers-Issard, and the scales are inspired by the old models of Heljestrand in tortoise.

(I can't however pretend that mines are finished as well as they were in the Kindal house ^^)

Edit : the original scales were those ones :

Last edited by Thaeris; 07-31-2014 at 06:39 PM.

-

07-31-2014, 11:13 PM #430

I'm reading Caswell's online introduction to buffing:

How To Buff And Polish - Caswell Inc

They give a table of thicknesses allowable for given motor sizes and wheel diameters. For instance, if you are using a buffer with a 3/4 horse power motor and are using wheels with a diameter of 4 inches, the maximum allowable width is 4.5". They say, "you may use multiple wheels to make up total permissible width." So if you were using wheels 4" in diameter and 1/2" wide, you could, theoretically, put up to eight wheels on a spindle.

I ordered a bunch of 4" wheels this morning and am thinking about putting multiple wheels on the buffer. Has anyone here done that? Any thoughts on how it works with razors?

Joe

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote