Results 121 to 130 of 156

-

11-02-2016, 02:43 PM #121

This is luxury camping, hot lather in the wild. My camping cup also serves as a scuttle. The plastic

insert is a microwave mac and cheese container I saved to make this gizmo. It works great!

Freddie

Freddie

-

11-03-2016, 03:31 AM #122

Just so you don't drink from your scuttle!

-

11-10-2016, 07:10 PM #123

As I've posted my newly acquired table top band saw is adjusted (Thanks to my Buddy Ski) and works nice. However the Made By the C. H. Ina Company didn't provide a storage place to keep the small Allen wrench that's required to make adjustments for the blade.

SO--a small bit of vacuum hose, some Barge, some painters tape to contain where the Barge would be applied, a little time for the two surfaced to dry, apply the hose to the machine, Press for a minute and Viola! Handy storage. Why the designers didn't include something like this is beyond me/maybe it would have cost a 10th of a cent more so there would be less profit

Last edited by cudarunner; 11-10-2016 at 11:17 PM.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

12-10-2016, 11:16 PM #124

I posted about my self given Christmas Present for this year here;

http://straightrazorpalace.com/works...ml#post1687757

I'm waiting for the stablizing solution to arrive (two more days) so in the meantime I decided to not actually place the wood or whatever directly in the chamber well at least if I can't help it. Here's my solution, I took a 7" wide by 3" deep aluminum cake pan, drilled two holes and used some 1/8" brass rod to make a handle. I"d tried to use some acid core solder to make a 'bump' that wouldn't clear the holes I drilled but I wasn't happy with the results so I heated the ends of the rod till they were red and then plunged them in cold water and then inserted the rod into the holes and used vise grips to bend them.

I'm fairly happy with the results:

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-20-2017, 11:48 PM #125

I really shouldn't post this but I will.

First and Foremost! Always Use Proper Eye Protection when using Any Air or Electric Powered Tool or Any Other Device Which Could Cause Injury!

I keep my Safety Glasses just inside the door to my garage:

It all started out innocent enough; I decided to clean up the Boars Nest and in the process I took the top off of my toaster and removed the crumb tray from the bottom so I could run them through the dishwasher and shook it out over the kitchen sink. However I could see that there was lots of debris left inside so I took it outside and then grabbed my Harbor Freight Blow Gun with the 2' extension to remove the crud.

and in the process I took the top off of my toaster and removed the crumb tray from the bottom so I could run them through the dishwasher and shook it out over the kitchen sink. However I could see that there was lots of debris left inside so I took it outside and then grabbed my Harbor Freight Blow Gun with the 2' extension to remove the crud.

While I was blowing the crud out the extension pivoted and when I tightened it it went past center. Well being anal as I am I decided to fix it.

So I took the extension out and cleaned the threads up, but then I noticed that the extension threaded into what looked like some kind of connector. So I removed the connector.

I'm sorry for the lack of pictures as this post is an afterthought. With that said, take a look at these pics.

Here's the website picture of the blow gun:

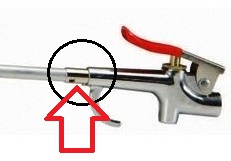

Now here's where the connector is:

That isn't really a 'Connector' what it is in reality is a 'restrictor valve' to probably please OSHA. While the extension is a little less then 1/4" ID there is a hole in that 'connector' that's about 3/32" + or - a bit.

SO! I removed the restrictor valve and placed it in my drill vice and used a 1/4" drill bit to improve the 'air flow'. The valve is hollow at the male threaded end but the restrictor hole is in the flush end.

I reassembled using Medium Blue Loctite to hold the new and improved restrictor in place and JB Weld to hole the extension in the position I wanted.

To say that the Air Flow at the tip of the nozzle was increased would be an understatement. Before it was like firing a 22 long rifle pistol and then firing the same pistol in 357 MAG.

I hope this will be of some help to some of you.

Work Safe My Friends!Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-20-2017, 11:55 PM #126

What you had was a pressure limiter. It's job is to prevent blowing bubbles in your blood stream,should you bump the nozzle against your skin to shut off the flow. Your skin would not see the 150psi, but a fraction of it.

JMTOTP. ~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following 2 Users Say Thank You to Geezer For This Useful Post:

cudarunner (06-21-2017), dinnermint (06-21-2017)

-

06-21-2017, 01:40 AM #127Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yup, I have heard of guys getting killed, playing grab a$$ with un-restricted blow guns.

You really don’t need that much pressure to blow most crud off.

Do be careful with it, especially if you have kids or grand kids. Everybody likes to play with an air nozzle.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Geezer (06-21-2017)

-

06-21-2017, 01:51 AM #128

While in my 64 years I've never heard of anyone being harmed by a air nozzle I suppose that stupidity will always conquer. To me it's like the warnings on Hair Dryers--Do not use in Bathtubs. Common sense seems to be a diminishing thing these days.

Anyway it will fit right in with the other blow guns that I've had since the 70's as they don't have the 'Restrictors'/'Pressure Limiter' or such (All came from the factory that way).Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-21-2017, 03:30 PM #129

We had this issue at work, well OSHA had an issue...

One simple remedy is to cross drill the tube. This way, if you cover the end of the tube with you palm, air can escape. If there isn't one, the theory is you can puncture your skin with air pressure.

Although, you don't have to worry about OSHA. If we didn't have to avoid getting fined (again), we probably wouldn't do anything about it.

-

The Following User Says Thank You to dinnermint For This Useful Post:

cudarunner (06-21-2017)

-

08-07-2017, 05:46 AM #130

Ever have a time when you needed a pair of pliers or Channel Locks that needed protection on the jaws so you didn't put marks or scratches on a chrome bolt or such?

I have always had a 10" pair of Channel Locks with about 3 layers of shrink tubing on them to do such a job, especially my last occupation. I would use the same size shrink tubing by shrinking one, then another the same size over it & a third piece. I get emails from Stew-Mac, the guitar people & they are always coming out with something really cool. I got an email the other day about some pliers they now sell with some replaceable nylon jaws, so I got me a pair. They cost $14.95 & are well worth it. I was going to get a set of the replaceable jaws also but they weren't available yet. I have already had to use them on a vintage Bang Olufsen stereo receiver in which a 1/8" billet aluminum part which holds the speaker jacks & pivots up for ease of connecting the speakers, was slightly bent. These arrived Saturday & I tried them & they worked great, not scratching the black paint.

Here's my Channel Locks I modified years ago at my last job.

The new Stew Mac pliers with replaceable nylon jaws.

-

616Likes

616Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote