Results 1 to 10 of 92

-

04-18-2018, 07:23 PM #1

Cloning celluloid scales: a work in progress

Cloning celluloid scales: a work in progress

A while back (sorry, Joshua, sometimes it takes me a bit to get to projects like this) a forum member asked me if I had a scale template for Case Temperite blades.

I recalled I have one that needed rescaling too, and thought I might have some scales in my scrap bin.

Well, the scales I had are that variety of transparent yellow celluloid that rots steel like nobody’s business. In fact, I had two pair of them (without a razor). One of the pairs had already shrunk and become horrible. Both were badly warped.

Unrelatedly, I had also bought some casting supplies thinking I’d try and clone some scales at some point. So I told Joshua I’d get right on it and try to make some replicas.

A month passed while shiny things distracted me, but, like I usually do, I found my way back.

The first thing I had to do was straighten out the scales.

Ladies and gentlemen, I am a professional DO NOT TRY THIS AT HOME.

So I put the good pair into my scale-flattening device (a pair of metal plates bolted together with springs so I don’t have to retighten as whatever is in it flattens), and stuck that in the toaster oven for ten minutes.

I repeat.

Do not put celluloid scales in the toaster oven, especially transparent celluloid scales.

But if you absolutely have to, low, low temperature is what you want. I cooked them at 160 degrees, and it worked. They went back to dead flat. The downside is that it accelerated their rot.

So I used TAP Plastic’s Silicone RTV molding material to make a mold of them.

The first attempt didn’t quite work. I placed the scales too close together, and I didn’t adequately seal the bottom, so some got under. That meant part of the wall separating the two halves tore so I couldn’t get a good impression off it.

Knowing where I’d gone wrong, I made a second casting, this time being more careful about positioning.

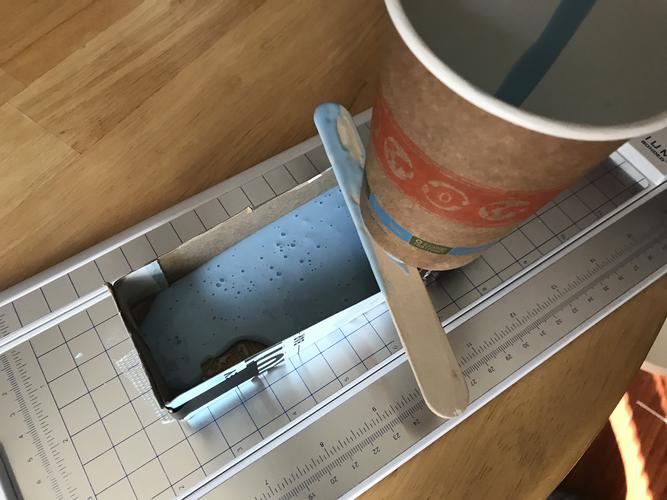

(What you see there is my easy bubble-removal system — put the mixed silicone into a paper cup with a hole in the bottom and let that slowly pour into the mold, the bubbles come out in the stream on the way down and everything works nicely)

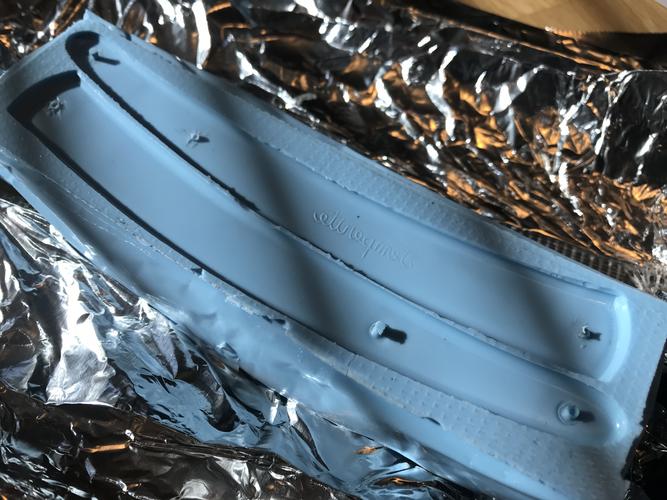

End result

Now, I’m almost certainly going to need to do a third mold of the scales, but first I need to get some wax I can use to fill in the marks where the pins were removed, but I figured it would be a good idea to start with the easiest method since next I need to see if the casting material is good for scales and what I can do with it once it’s cast.

(This is a picture of the second attempt at pouring scales).

I used the ‘bad’ mold as well as the good so I’d have one pair of scales I could do various possibly destructive experiments on and another I could just use if those experiments pan out.

The first attempt at a pour ... did not go well. I looked at the wrong mixing instructions, and I mixed in my dye before adding the hardening agent, which screwed up the mixing ratio. The result of that was a material with the consistency of pitch and me spending 90 minutes trying increasingly desperately to get it. OFF. MY. HANDS.

The secound attempt is working as expected, but still needs to fully cure (it takes about 72 hours for the material to hard cure). In the meantime, the ‘experiment’ scales show about what I can expect.

They’re still a little soft though. :P

(That’s aftert 24 hours).

Also noteworthy — the original scales were that golden yellow color. My first resin attempt was red because that was the only color dye I had (my plans for casting scales didn’t originally involve cloning those honey-colored ones).

This second attempt, I tried using food dye. And it worked! Except that the yellow food dye turned this lovely ruby-red. Oh well.

I’ve got the proper yellow dye for the final results, but that’s pending the full cure on these to see if it will be structurally sound enough for use.

I’ll update this thread as I go.

Down the road, I want to try brass embedments (Dubl Duck style), and also pearlescent casting, which I have the pigment for. But that must all wait until I have validated TAP Plastic’s ‘EasyCast’ resin for the purpose of scales. Based on the samples in the store, I think it’s gonna work great.

One huge benefit of the mold and casting materials I’m using here — no shrinkage.-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following 22 Users Say Thank You to Voidmonster For This Useful Post:

32t (04-19-2018), BanjoTom (04-20-2018), Benz (04-18-2018), BobH (04-18-2018), DZEC (04-18-2018), easyace (04-19-2018), Gasman (04-18-2018), HARRYWALLY (04-20-2018), JP5 (04-18-2018), markbignosekelly (04-23-2018), Matt1222 (04-19-2018), MedicineMan (04-19-2018), MisterClean (04-21-2018), MrZ (04-19-2018), nipper (04-19-2018), Oldnick (04-19-2018), outback (04-19-2018), petercp4e (04-19-2018), randydance062449 (04-20-2018), RezDog (04-18-2018), sharptonn (04-18-2018), tintin (04-18-2018)

-

04-18-2018, 08:42 PM #2Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

Absolutely nothing to apologise for. I certainly appreciate the offer to make extras if/when you got around to it. Considering how common Temperites are, I can't believe I found someone that also needed to rescale one!! Glad you made a thread, this would be an awesome project got someone wanting to duplicate scales in acrylic instead of horn/wood.

You mentioned being distracted by shiny things. To quote a HS friend, "I don't have ADD, I have OSO Ooh! Shiny Object!"

-

The Following User Says Thank You to JP5 For This Useful Post:

Voidmonster (04-18-2018)

-

04-18-2018, 09:28 PM #3

Excellent, Zak!

Whoa! I just heard a tiny voice from the drawer saying 'ME! ME!'

Seems someone overheard!

-

The Following User Says Thank You to sharptonn For This Useful Post:

Voidmonster (04-18-2018)

-

04-18-2018, 09:45 PM #4

I really wish I could blame this on ADHD, but alas, I just have a huge backlog of stuff I have to prioritize. On the plus side, I think this train is coming right into the station! I’m going to get what I need fix the scratches in the sales and take a third mold of them tonight, and I’m really pretty confident this is going to work now.

Man though, I am not kidding about the horror of that resin mixed with the wrong ratio. It did actually, literally take me 90 minutes to get it off my hands and it took skin with it.

So let this be a warning to those following in my footsteps, if you use TAP EasyCast resin for scales, the instructions aren’t kidding around about not deviating from the 1:1 mixing ratio! Dye comes after mixing or it will botch things.

So, whaddya think — should I improve the original design by making the ‘Temperite’ logo on the scales be a solid, opaque red or just do what the originals did and haphazardly slap a little red paint into the impression of the letters?-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-18-2018, 10:38 PM #5

Oh! Definitely red paint in the stamps. I have a decent original one at home.

If you need the scales for this, Let me know!

-

04-18-2018, 10:45 PM #6

Paint it shall be! Though I think I’m gonna fill the letters on my personal one. :P

I think the scales I’m using will be fine once I fill the scratches with wax, as long as they make a good mold, it doesn’t matter if the originals look like celluloid with bits of wax in them!-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-18-2018, 11:18 PM #7

thank you Zak for sharing. I've toyed with the idea myself but was never sure what materials to use. I look forward the seeing more.

-

The Following User Says Thank You to tintin For This Useful Post:

Voidmonster (04-19-2018)

-

04-18-2018, 11:50 PM #8Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

Nice project Zak. Think the silicon is less prone to shrinkage than latex rubber molds as well, from personal experience.

Looks great!

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following 2 Users Say Thank You to MikeB52 For This Useful Post:

sharptonn (04-19-2018), Voidmonster (04-19-2018)

-

04-19-2018, 01:55 AM #9Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

An opaque fill sounds like a great idea! If that turns out well please give mine the same treatment! That could definitely be an improvement over the paint. If you had sent it to me blank, which I expected, I was just planning to use red paint in mine. That is all I would have been able to do here.

Sounds like this blade may turn out to be a gem by the time it's all said and done. I was just going to make acrylic scales as close to the originals as possible by using pictures online. I didn't know Sharptonn had a scale I could have copied! lol

Seriously though, looks like it worked out for the best if the TAP resin works well.

I haven't shaved with my 25 yet, but it certainly seems like a well made blade, even if the scales shrunk and fell apart.

Thanks again Zak. And don't worry about me waiting. Good things often take time and it isn't like you asked for a deposit and gave me an ETC!

-

The Following User Says Thank You to JP5 For This Useful Post:

Voidmonster (04-19-2018)

-

04-19-2018, 02:54 AM #10

It's a great idea. The old ones are crumbling. They did even back in the day, as soon as they were sold. The DublDuck satinedges were and are horrible.

I have a pair of improved formula NOS replacement scales to attest to that.

Some Cell is quite nice and stable. Some is horribly prone to disintegration and ruining themselves and their respective blades.

I told someone earlier today who was showing a razor coming their way to look out. Signs were there. Some cleanup had been done.

Raising the alarm to guys about the possibility of this is the right thing to do.

Esp as you see it over and over. JMO

I am excited to have someone come up with a way to replicate these scales and transfer inlays and bolsters so they can live onward.

178Likes

178Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote