Results 21 to 30 of 92

-

04-19-2018, 10:23 PM #21

Like polyurethane soles on shoes that are not designed to last.

Use them or loose them.

-

04-20-2018, 01:12 AM #22

I've cleaned up the scales I'm casting and minimized the scratches from pin removal, gotten more Silicone RTV, and poured a new mold.

By tomorrow the scales I poured should be getting close to cured (though thinner pieces apparently take longer, booo).

It is officially time to just wait.-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-20-2018, 01:17 AM #23I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Very cool!!! I want to try the same with a silicone mould. I'll be following along in your journey.

Burls, Girls, and all things that Swirl....

-

The Following User Says Thank You to HARRYWALLY For This Useful Post:

Voidmonster (04-20-2018)

-

04-20-2018, 01:20 AM #24

-

The Following User Says Thank You to Voidmonster For This Useful Post:

HARRYWALLY (04-20-2018)

-

04-20-2018, 01:24 AM #25I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

We have a brand new art store very close to me. The fella that works there is super helpful. When I bought the polyester resin, he also tried to sell me some silicone. Haha. Maybe a little too helpful. If I do make a silicone mould, I want to do something that can be used more than once. Maybe a classic twist scale.... Is that what they're called????

Burls, Girls, and all things that Swirl....

Burls, Girls, and all things that Swirl....

-

The Following User Says Thank You to HARRYWALLY For This Useful Post:

Voidmonster (04-20-2018)

-

04-20-2018, 01:29 AM #26

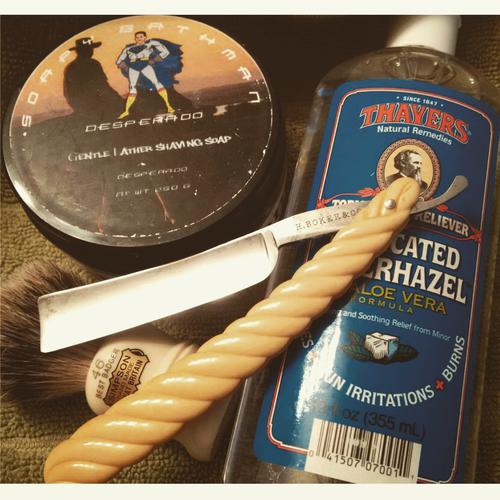

Rope? Twist? Something like that.

The downside of the silicone mold stuff is that it isn't cheap. $25/lb (though the 4 pound version gets a nice price break).

My ultimate goal with this stuff (aside from being able to clone problematic celluloid scales) is to make my own Shivering Beggar scales to put old hardware store razors in, hone'em up and sell'em for $55-65 (with info about the hardware store they came from). That's still a goodly way down the road.-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-20-2018, 05:01 PM #27

Well, it wasn't quite a full 72 hours, but the last resin pour has not noticeably hardened since I took the spare ones out of the mold over a day ago, so I'm gonna call those failed too and blame it on the food coloring I used to dye them (maybe the yellow dye turning ruby red was a clue that a chemical interaction had occurred, huh?)

So, with a freshly decanted, very clean mold ready, I mixed up more resin this morning (using the correct dye and the correct color!) and poured three sets.

Let's see how this goes!

-Zak Jarvis. Writer. Artist. Bon vivant.

-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-20-2018, 07:29 PM #28

-

04-20-2018, 09:45 PM #29

-

04-20-2018, 10:07 PM #30I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

standing by.....

Burls, Girls, and all things that Swirl....

178Likes

178Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote