Results 131 to 140 of 155

Thread: Paper testing razors

-

02-03-2015, 02:36 AM #131"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

I am late to this discussion and my comment may be of little value. The lack of objectivity in testing has already been mentioned. A contrary positive is that the testing mentioned falls within measurements that have been traditional for razors probably since the days of early manufacture, e.g. personal subjective judgement and the "feel" of the user. I suspect there is a much stronger volume of measurement via touch/shave than there is for using paper to test razors.

Here is a thread from a site known for better than average objectivity about their products and an author known for a mild obsession with objective testing and a good sense of statistical analysis. Spyderco Forums • View topic - Edge retention slicing cardboard (15 dps, x-coarse DMT)

With the exception that the paper material being discussed is cardboard and that the blades are knives, there are very valid principles of analysis and the discussion of several variables that can readily transfer to this discussion. If anyone is interested...

From this external thread's perspective the paper variable is the greatest threat to the argument for testing with it unless multiple cuts are made, at a volume that becomes prohibitive, or specially calibrated paper is used for multiples of cuts. In the end, the paper is the limiting variable, not the edge, as Oz has noted with his report of different edges shaving well. The Spyderco thread reinforces the notion that paper cutting is damaging, not enhancing to a blade's edge. It also discusses the bias that creep into any such analysis no matter how well intended.

This thread need not close as there is more to learn. The question remains if the length and rigor of such study is practical when the methods advocated here are not broken.

-

-

02-06-2015, 07:17 AM #132< Banned User >

- Join Date

- Feb 2011

- Location

- Southern U.S.

- Posts

- 110

Thanked: 22

Thank you for your comments, and the link. The information on the link is very interesting. I did not find much correlation. As the writer notes, he used any cardboard he could find, and his testing was for much different purposes. About the only real correlation I could find that was sharp steel instruments were the subjects of the tests, and a paper products was used as the test medium. I use paper I buy. About as consistent, convenient size, and proper thickness for the intended use as I have found. He used any used cardboard he could find, and didn't say if he attempted to check moisture content. He tested to compare steels, and I test to check progress of the honing progression, and am simply looking for improvement of the test results along the way. My testing is totally subjective, and not as useful for someone very new to the test, other than the difference between the test results for 600 grit and 10,000 grit are as obvious as night and day. Differences of 20-30 laps on a given stone may not be so obvious, with much less experience. You mention multiple cuts needed for the test, but my tests use one cut at a time, at different spots in the progression.

It has been pointed out here, and I completely agree, that many of us have little need for testing beyond 1K. My original statement was to a new honer, and that was probably my biggest mistake. My test is evidently not so easy to perform and get usable results from as I had assumed. The newbie was looking for 'easy' and this evidently does not fit that description.

For most people here, the time and effort to acquire the necessary experience to get a lot from my tests, is probably not worth the effort. It may be more useful for someone testing lots of stones, as an initial indication, but even that would be questionable.

Thanks again,

Cheers,

-

02-06-2015, 04:53 PM #133"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

No problem. I appreciate that you followed the link. Rather than focus on individual variables like test conditions, the type of material and the steels, I suggest taking a wider view of how Cliff describes the process. In the end, his point is investigational bias and how it can result in Type 1 or Type 2 errors and how the investigator can come to an entirely unlooked for conclusion when bias is addressed, as he did when he found himself testing paper and not steels.

I can apply this doctrine to both sides of this discussion. There are a number of threats to validity that appear in both places. The balance shifts, however, in favor of the larger sample size represented by the study group here. This is not to say that your perspective does not have a place, it's simply a matter of addressing biases and the threats to validity in your supposition. There is still a lot to learn.

Time will answer a lot of questions. It's really too bad that you have raised a portion of the discussion that may have already been beaten to death a hundred years ago, or more, but that information lost to history. Now you're left in a position to prove your point and limited references except those in your own shop. Keep good notes so it doesn't get lost again.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Geezer (02-15-2015)

-

02-06-2015, 05:23 PM #134

I think just keeping the perspective that the test is a subjective, probing test takes a lot of the importance of the materials away. I use the HHT and that has similar issues with the hair being used. I have three distinct types of hair from the same lock of my hair that I use and calibrate my expected results to each type of hair. It is not an objective test, but I still find it useful.

-

The Following User Says Thank You to bluesman7 For This Useful Post:

bigeasy1 (02-07-2015)

-

02-06-2015, 08:52 PM #135

-

The Following User Says Thank You to Bruno For This Useful Post:

bigeasy1 (02-07-2015)

-

02-07-2015, 03:20 PM #136< Banned User >

- Join Date

- Feb 2011

- Location

- Southern U.S.

- Posts

- 110

Thanked: 22

-

02-07-2015, 03:50 PM #137< Banned User >

- Join Date

- Feb 2011

- Location

- Southern U.S.

- Posts

- 110

Thanked: 22

Thanks. As you mention, this has probably been beat to death over a long period of time. I would think that it would be exceedingly difficult to devise a completely scientific, objective test, to search for a subjective result.

Although it is important in any test to consider all of the variables, I am not certain that could be done, considering the dozens if not more, variables that will effect the final ultimate test, which is subjective only. I have attempted to keep my medium as consistent as possible, but things such as consistency of angle of approach, pressure, blade intersecting angle to the medium, speed of the cut have to be considered as well.

I suppose a very sensitive sound meter could be used to detect sound variation in individual test cuts, but that is only one of the results giving feedback to the user, and that test would not be used by the layman. It could only prove that there is some validity to the mention that the sound changes. Anyone could prove this to himself simply by listening while making a cut.

But, the principles of scientific testing are still very important. For most consistent results, one must consider the possible variables and ensure that each is handled as consistently as possible. They don't have to be the same as the next guy uses, but do need to become consistent for the individual using the test. This applies to honing and shaving as well. It is best to develop some technique that works for the user, before experimenting with variations such as different shave prep, or a new style of hone.

-

02-07-2015, 04:19 PM #138< Banned User >

- Join Date

- Feb 2011

- Location

- Southern U.S.

- Posts

- 110

Thanked: 22

Mike Blue:

"Time will answer a lot of questions. It's really too bad that you have raised a portion of the discussion that may have already been beaten to death a hundred years ago, or more, but that information lost to history. Now you're left in a position to prove your point and limited references except those in your own shop. Keep good notes so it doesn't get lost again. "

My original point was that cutting paper to check the progress of honing, works for me, without destroying the edge. After enough flaming, my point became, and was never intended for more than to prove the nay sayers shouting "that will destroy the edge" wrong.

I do not have the time, inclination, training, or equipment to prove much of anything beyond that. I do appreciate all of the comments here, and will be around to see what develops and attempt to answer any questions that may be aimed at me.

Thanks

-

02-09-2015, 06:51 AM #139< Banned User >

- Join Date

- Feb 2011

- Location

- Southern U.S.

- Posts

- 110

Thanked: 22

Touched up that razor in the picks tonight. Well, actually just 40 fast laps on the cloth strop.

Shaved so nice, I had to look in the mirror close and run my fingers over my cheek to make sure it did its job. Still has the paint on it, may have to look to see if stropping got that chip out. If not, didn't bother the shave any, after stropping of course.

Cheers,

-

02-13-2015, 03:26 AM #140< Banned User >

- Join Date

- Feb 2011

- Location

- Southern U.S.

- Posts

- 110

Thanked: 22

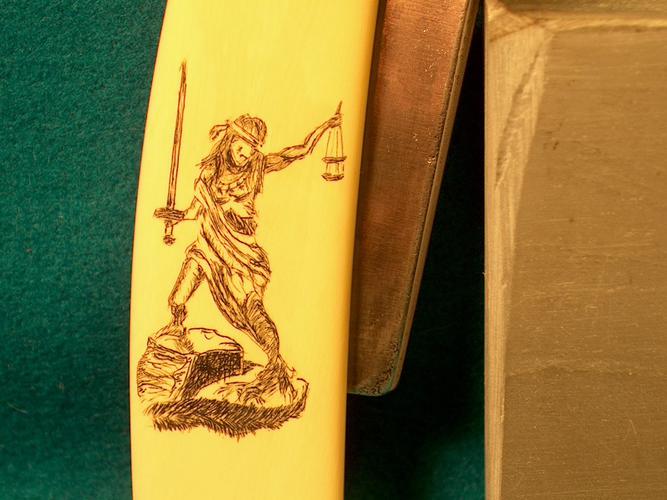

There seems to have been a number of readers, but no posters. Certainly others have had some experience here? Well, I honed the razor below this past Sunday, using my normal methods. I thought a little "eye candy" might tempt a few to post. I read in an older thread here that the George Brittain razors were made about 1820-30. One poster asked if they shave good and another answered not good enough to justify the price at the time. Guess a great many things a relative. My finishing honing was with the la roccia stone until I could find no further improvement of the edge, and then followed 40-45 fast laps on cloth, flowed by a single test cut. The first two swipes were as good as it gets. Smooth, no drag, no sound, no feel, as though someone had rounded the edge, but closer look in the mirror revealed nothing but smooth soft skin. The owner did not mind my test methods. This is the first GB I have touched, and only did the two swipes, so have no idea how well it holds an edge, but it certainly took a very fine edge fairly easily.

Enjoy!

147Likes

147Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote