Results 11 to 20 of 88

-

04-09-2013, 01:28 PM #11

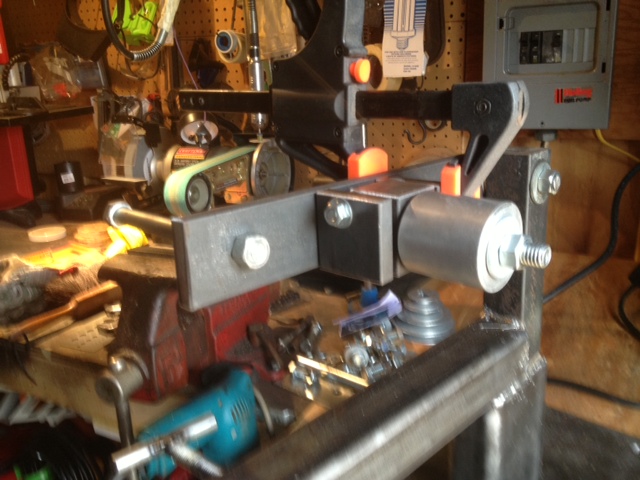

Shortened the upper tensioning arm this morning and thru a bolt on for a handle. Got a "free" tracking wheel today from a friend who is a knifemaker... Also a belt so I can hopefully get this grinder completed soon. When I started this project I had no mesurements, so I'm just flying by the seat of my pants, looking at photos and taking educated guess's on how to make it...

-

04-09-2013, 10:02 PM #12aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Looking good man, talking about full steam ahead! I like it!

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

04-10-2013, 01:01 PM #13Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

That seat of your pants method works for me too. Looks like your going to have a nice grinder when your finished. Way to go !!

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

04-10-2013, 03:14 PM #14

-

04-10-2013, 03:20 PM #15

Well, I fabricated the tracking assembly today. Just gotta drill an tap a hole for the adjusting bolt in the arm and weld the tracking assembly into place... Pillow blocks will be arriving tomorrow but I'm not sure I'm gonna be able to get anything done. Probably more on Friday... In the mean time some more photos to share.

-

04-10-2013, 03:39 PM #16

Looking at the KMG setup, I think it would be beneficial to crown the tracking wheel a bit on the sides.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

04-10-2013, 04:24 PM #17

-

04-12-2013, 05:01 PM #18Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

You can crown the tracking and drive wheels with a layer or two of strapping (filament) tape in the middle of the wheels, if you don't have a way to machine them. Looks good so far. +1 for seat of the pants engineering.

-

The Following 2 Users Say Thank You to skipnord For This Useful Post:

randydance062449 (04-16-2013), spazola (04-12-2013)

-

04-12-2013, 08:05 PM #19

Thanks. I was actually thinking about tape but wasent sure if it would work. Guess I got my answer...

Ordered an 8" contact wheel and 4" drive wheel from USAKNIFEMAKER.com with bearings already in them. That should be the last of my parts list... I think

Last edited by officerdread; 04-12-2013 at 08:11 PM.

-

04-13-2013, 04:27 AM #20Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Bearings in a drive wheel ?

Good judgment comes from experience, and experience....well that comes from poor judgment.

48Likes

48Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote