Results 51 to 60 of 88

-

04-18-2013, 07:59 PM #51Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

04-18-2013, 09:05 PM #52

-

04-18-2013, 09:06 PM #53

No one siad this was going to be easy... The good news is the contact wheel is in. Bad news is the drive wheel is backordered 1 to 2 weeks...!

-

04-19-2013, 01:47 AM #5450 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

-

04-19-2013, 03:25 AM #55

-

04-19-2013, 06:38 AM #56

-

04-19-2013, 07:03 AM #57

-

04-20-2013, 06:44 PM #58

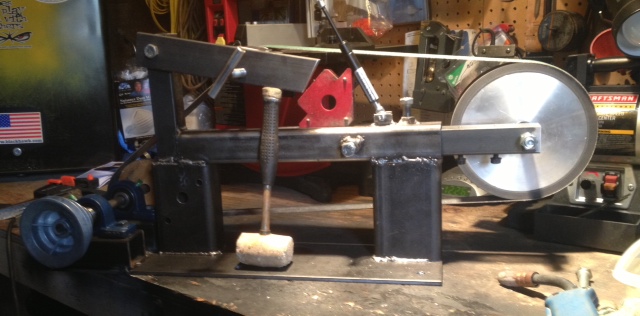

UPDATE

Gas strut came in. I figure with the 8" wheel the bottom belt will be at an angle from the contact wheel to the drive wheel. If I would change to a 10" or 12 " contact wheel it will straighten the angle. Attached the tracking wheel as well as added the gas strut.

Last edited by officerdread; 04-20-2013 at 11:09 PM.

-

04-21-2013, 01:24 AM #59Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I think if you change the angle, you will change the amount of force on the idler arm. I think you should mount it as close to a right angle to the idler arm as possible - like the hammer in the mock up. Any mechanical engineers that can confirm this?????

-

04-21-2013, 03:32 AM #60

48Likes

48Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote Funny guy... I guess I should really proof read my posts before hitting the post button eh...?

Funny guy... I guess I should really proof read my posts before hitting the post button eh...?