Results 31 to 40 of 88

-

04-13-2013, 11:23 PM #31

-

04-13-2013, 11:28 PM #32

As for the belt tension this is what I was going by. Going to do more research.

http://www.youtube.com/watch?v=wsHMY4O7nGI

Anything concerns are welcome as this is not something I fab every day...Last edited by officerdread; 04-13-2013 at 11:37 PM.

04-14-2013, 06:13 AM

#33

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

your right, I looked around and the 30 to 35 pounds sounds like what they use. Seems high to me is all. On this particular vid it looked like this guys idler was moving even after start up. I am thinking that the start up torque and the loose set up may be fixed with more tension but is that best for the belt? I have to find my fish scale now and check my grinder. It has no problems tracking or pulling to the side. I just pulled on the handle and it feels like it's about 10lbs but it is a completely different set up. At the wheel, the tension may be a lot more. When I re purpose it to a 72" I will know how well I did if it still tracks right without problems. :<0)

Good judgment comes from experience, and experience....well that comes from poor judgment.

04-14-2013, 01:49 PM

#34

04-14-2013, 01:53 PM

#35

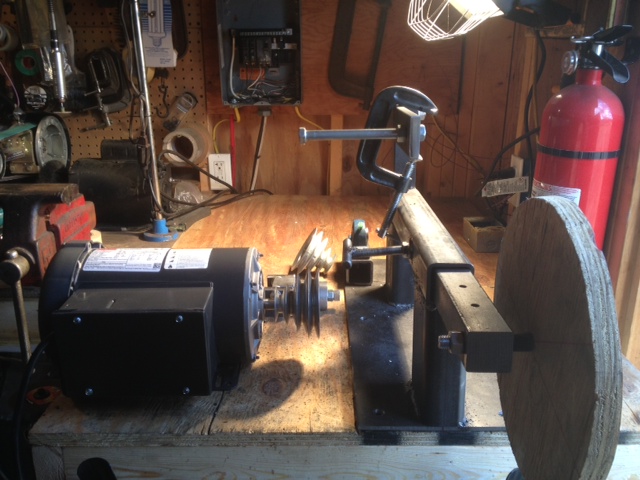

A little more progress. the motor is up and running. tac welded the hinge on the base plate. Also changed my mind about using one flange bearing on the leg of the machine for the drive wheel. Going with two pillow blocks. Keep it simple. Also I think Im going to change the position on my bench. More room but close to the door. Don't have much of a choice in a tiny shop.

04-14-2013, 03:09 PM

#36

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I'd agree that the setup in the video looked like flex in the idler pulley was causing the belt to "kick" when he started it up. The spring on my KMG seems to be no where near 30 lbs..When I change belts, I back off the adjusting screw on the bar that holds the contact wheel and slide the bar in to give me slack in the belt. I retension the new belt by pushing down on the spring, pulling out on the bar, and then retightening the locking screw. I'd suggest checking the tension on some of the factory belt grinders before I bought a 35# gas strut. Too much tension may be a factor in belt "explosions". I haven't had one yet.

04-14-2013, 10:46 PM

#37

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

Ok, I was wrong. I checked the compression spring on my KMG. Wire is .15 inches, and uncompressed length is 3 inches. When I compress it to tension the belt, the length goes to 2 1/2 inches. The best I could do for weight to see how much it took to compress it was 20 lbs. compresses it 1/4 inch. I don't have any higher weights of a convenient size, so ---- it looks like 30-35 lbs. is just about right. If you try a 35# gas strut, be sure to let us know how it works.

04-15-2013, 10:13 PM

#38

Will do. 30 to 35 lbs seems to be the popular consensus within specs...

04-17-2013, 11:14 PM

#39

Ordered a 30 lb gas strut. Contact and drive wheels arriving tomorrow.

04-18-2013, 02:09 AM

#40

Precision drill rod arrived, 5/8" 0.6250" and won't fit in my 5/8" pillow blocks or my step pulley... The rod on the motor fit the step pulley like a glove. Suggestions?

48Likes

48Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote