Results 11 to 20 of 126

-

03-07-2016, 03:17 AM #11

To measure the angle, do I just measure the spine thickness and height of the blade in several places and take an average for the angle?

Also, I have a 325 DMT, Norton 220 and 1K. Should I use the 1k, as normal, or should I try the 220 or DMT for a while, to get through some metal?Regards,

PCM

-

03-07-2016, 03:49 AM #12

+1 for 4 or more layers of tape & the Marker

I have spent 4 hours grinding a wedge from 4 layers of tape back to 1 layer on my 1k Nanni before getting the Diamond honeSaved,

to shave another day.

-

03-07-2016, 06:15 AM #13At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

This is the Google friendly calculation, that means you can change the variables of the Spine width (Shown here at .181) and the size of the blade (Shown here at .620 ) and copy it to Google and get the actual bevel angle (Shown here at 16.78)

(2 * asin(.181 / (2 * .620)) * 180) / pi = 16.786646

And yes you can begin the real work of the Bevel Restoration on some serious cutters but remember when you adjust the bevel angle using tape this might be really easy

Use the MM test it will really give you an idea of what is going on there

-

The Following User Says Thank You to gssixgun For This Useful Post:

pcm (03-07-2016)

-

03-07-2016, 10:44 PM #14

Last edited by pcm; 03-07-2016 at 11:15 PM.

Regards,

PCM

-

03-07-2016, 11:17 PM #15

I thing the calculation should be atan() and not asin(), although that still comes out to 17.6 degrees.

Regards,

PCM

-

03-08-2016, 01:10 AM #16

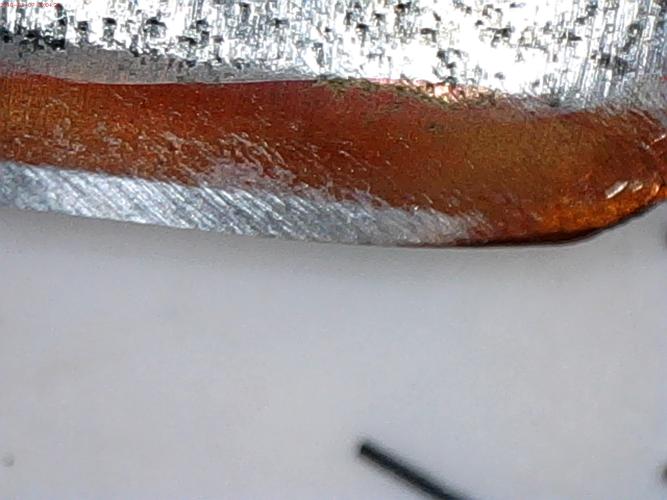

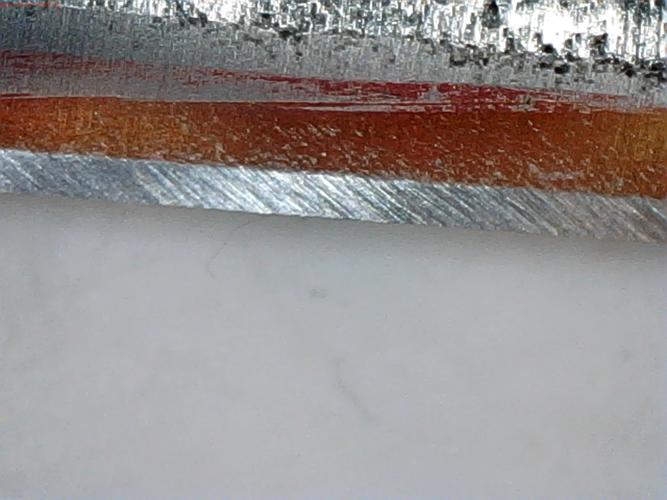

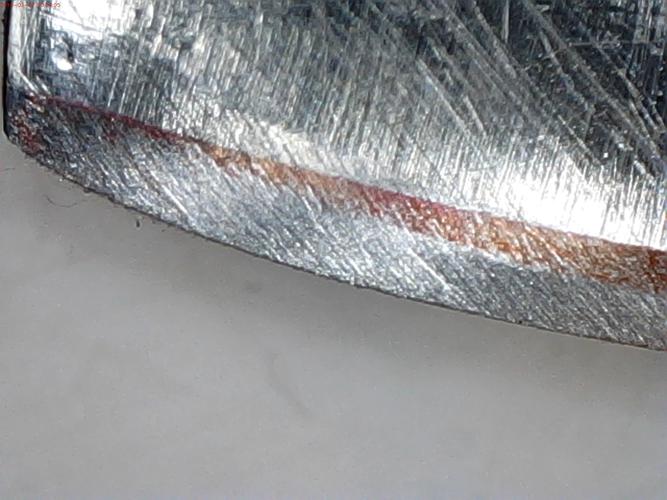

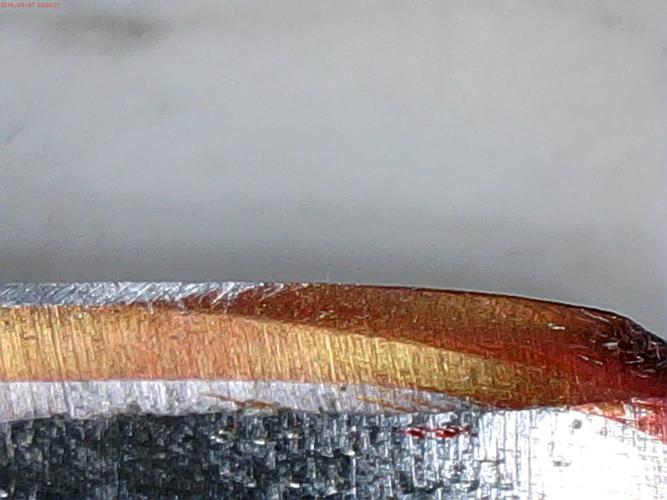

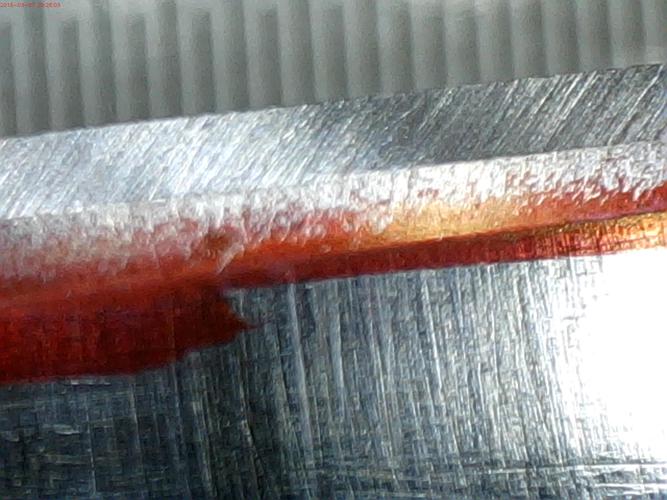

OK. I did 5 layers of tape, used the 220 Norton stone (after flattening with DMT), and about 20 rolling X strokes with heel forward. Before replacing the tape, I inked the edge and here is how it looks after two strokes on each side:

I can't seem to get to the heel at all, and will work on exaggerating the stroke on the toe to see if I can get the tip. The new bevel widens a bit, towards the toe, but not too bad (relatively speaking).

I'll go a bit more tonight, and see if I can do better.Regards,

PCM

-

03-08-2016, 01:41 AM #17

OK, stopping for tonight. Will pick up on Thursday, and see what people say about the progress (if any

).

).

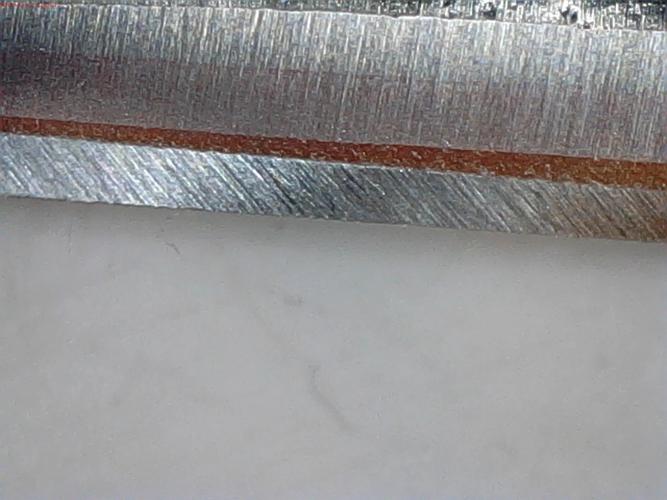

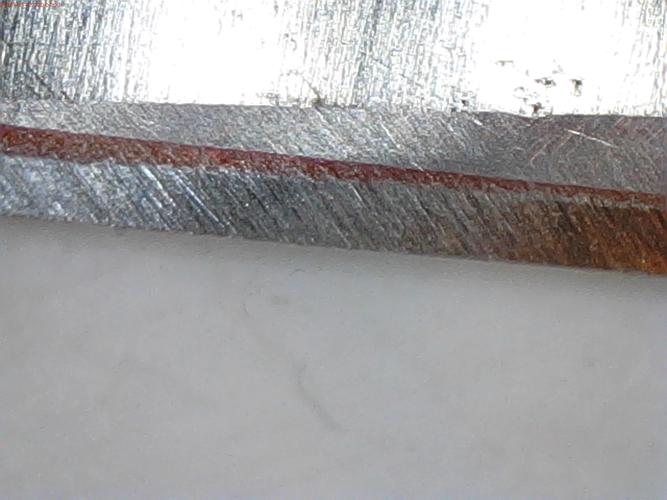

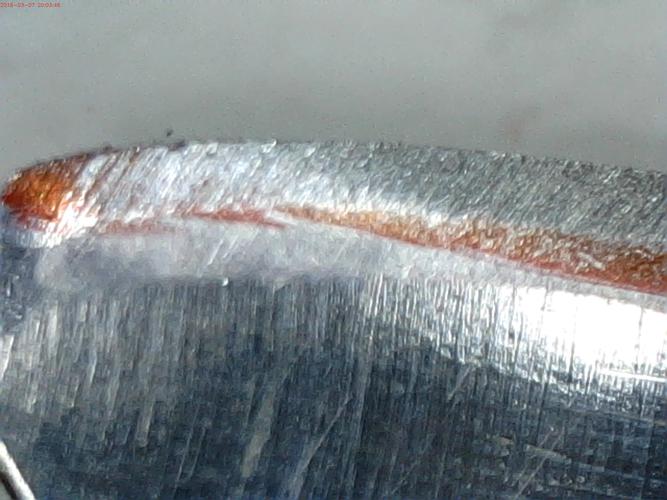

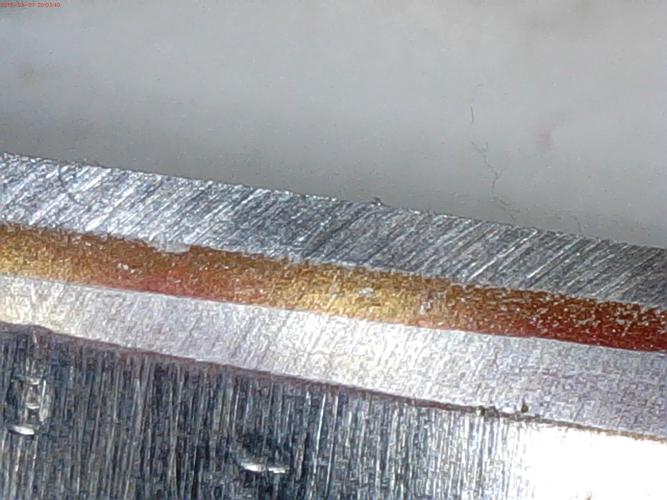

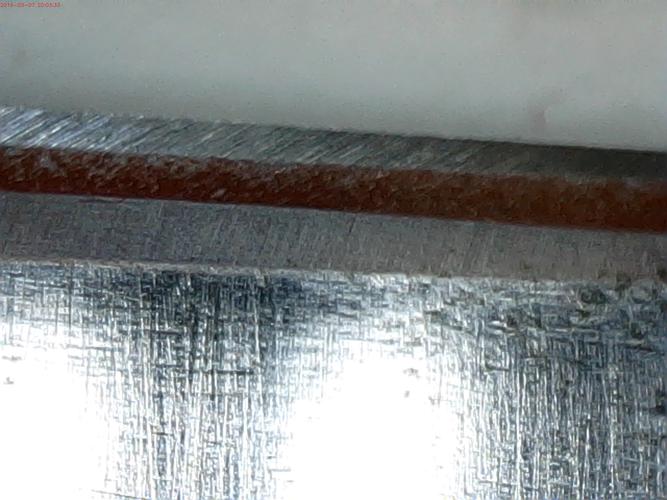

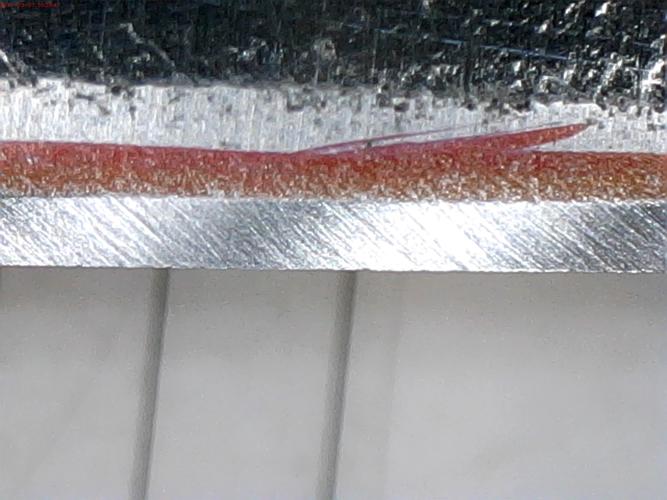

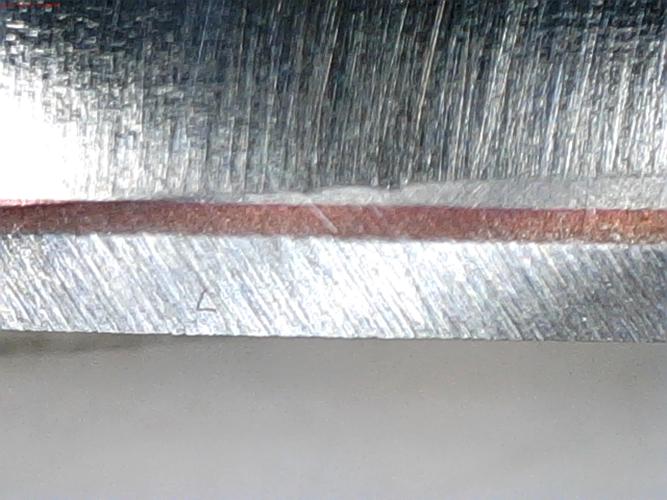

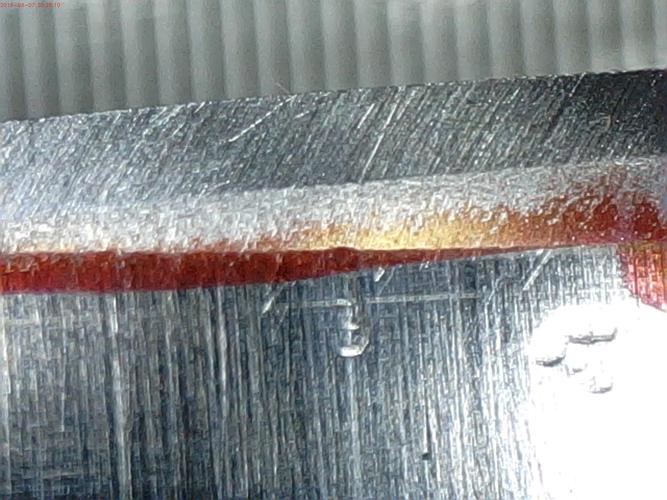

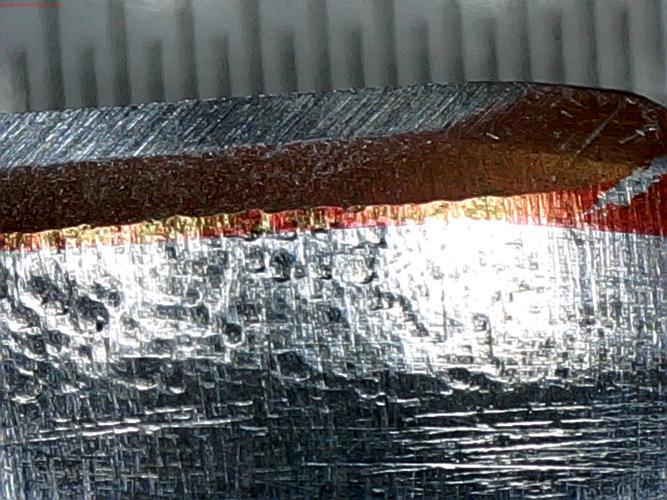

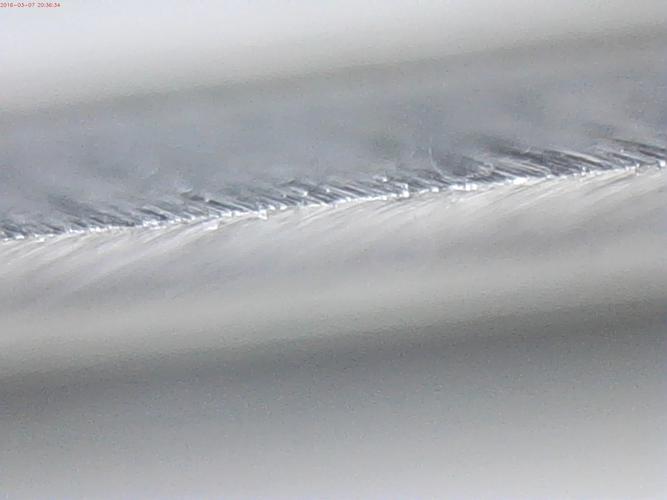

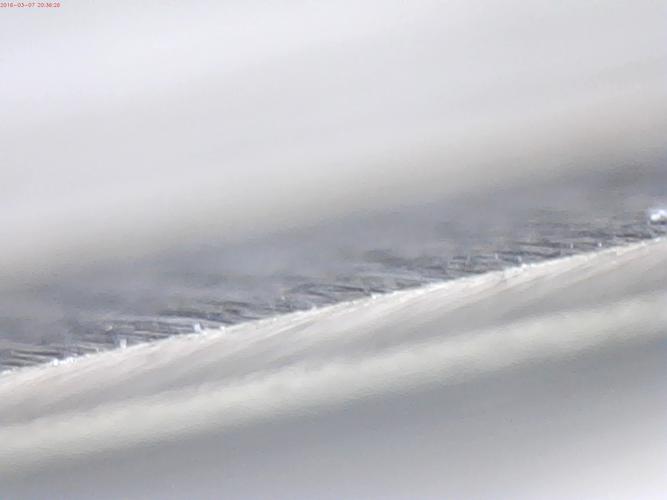

I'm getting close on the toe and heel, especially on the right side (as you look down on the blade with the scales toward you). I seem to do better at pushing the blade away from me, than pulling towards. I did two strokes, inked, and here's what it looks like:

I tried a marking prior to these, and didn't do as well, so clearly, I'm not consistently getting to the toe/heel. Here are some shots along the edge, at higher magnification:

It doesn't cut arm hair at all, and doesn't feel sharp to a TPT, and with my inexperienced measurement, it seems duller than before (expected, with the 220 grit, I'd assume).

Think I should go more with 220, or try stepping up to the 1K Norton?Regards,

PCM

-

03-08-2016, 01:53 AM #18

It seems to me you've nailed the stroke enough and have enough of the bevel meeting to progress to 1k and see what happens. More experienced gentlemen may have a better answer. Although looks good so far....

-

The Following User Says Thank You to dinnermint For This Useful Post:

pcm (03-08-2016)

-

03-08-2016, 03:43 AM #19At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

On the 220 it should feel "Knife" sharp from heel to toe..if it does then move to the 1k and see if you are in a real bevel setting area..

-

The Following User Says Thank You to gssixgun For This Useful Post:

pcm (03-08-2016)

-

03-09-2016, 06:22 PM #20

117Likes

117Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote