Results 271 to 280 of 281

-

05-03-2023, 04:04 PM #271

-

05-03-2023, 04:05 PM #272

-

05-03-2023, 04:17 PM #273

Random brand = random product and random results. The idea here is to eliminate randomness. A random edge rather sucks, since there are a gigaquantomegajillion ways for an edge to suck but only one way for it to be excellent.

That said, many vendors I THINK are selling rebranded 3M film. For instance, NanoLapTech's type 26M is obviously rebranded 3M. ThorLabs sells good film that seems to have thicker substrate than 3M, in the bigger 9" x 13" sheets, but they do not sell 1µ. Of course there are decent quality films to be found, but you might have to kiss a lot of frogs before you find your princess. All films are not alike. I strongly suggest you NOT use a random brand or unbranded stuff from a dodgy vendor or a random knife sharpening supplier or worse. You won't know whether to put the blame on your technique, or the film, which puts you back at square one in your emergence from the wilderness.

Just because a product is reputable, doesn't mean it works gangbusters for honing razors. There are even fantastic, highly prized stones that are not so great for honing razors.

Tell you what. Let me see if I can spare a sheet of film, and I will cut it and send it to you. I also have a few blocks of acrylic that I don't need because they are not my super-thick preference, but you could glue two together, or even drill, tap, and screw them back to back, since they are all 1/2" or 3/4" thick. I normally don't send ANYTHING outside the country because I can't be bothered with customs declaration, etc. You can paypal me for the shipping later, if you like. The film and the acrylic are on me.

-

05-03-2023, 04:36 PM #274

NO, please don't try to use a stone! Use acrylic or another very very flat, non flexing, non warping, highly polished surface that is still light enough for honing IN HAND. A stone SUX for that, and it is almost always too small. The smooth non grainy surface is needed for the suction that sticks the film to the plate. Don't be a Random Brandon. Don't fall back into the "random technique give random results" trap.

When a listing says "lapping paper", "polishing film", "polishing paper", etc, usually it is just a dodge to avoid returns due to a shipped product not being proper lapping film. Deception. There is no reason not to call genuine lapping film, "lapping film".

I strongly suspect that Lee Valley's 3M AlOx film is type 262x but you can ask them before you pull the trigger. 3M only makes a few types of film, though they do make them in various form factors such as round disks or small rectangles, which is fine for polishing fiberoptic cables but sucks for honing. Anyway 3M only makes three or four types of AlOx lapping film. Give them a call or shoot them an email. Don't roll the dice and go all random again, without at least trying to find out.

-

05-03-2023, 04:42 PM #275Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,465

- Blog Entries

- 1

Thanked: 4207

Lee Valley is the place, and that 3M film is one of the best, most reliable on the market.

That particular line being Mylar backed, not paper, and fantastic for tang stamp preservation as it is stronger backed and doesn’t dish into the razor when against a firm backer plate.

https://www.leevalley.com/en-ca/shop...g?item=54K9301

Abrasives are either silicon carbide or chromium oxide.

I purchase most of the tools I care about, for projects equally important, there.

Good luck.Last edited by MikeB52; 05-03-2023 at 04:52 PM.

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

05-03-2023, 04:47 PM #276

Congratulations on the successful shave! Now maybe try a different razor and see if you can duplicate those results. Then you will definitely be ready to have a go at a real finisher. You CAN match Paul's edge once you got your ducks in a row. When you get your Gold Dollars, don't be afraid to use a heavy hand to set the bevel and do NOT tape the spine. Spine wear is actually a good thing for them, because the bevel angle is very obtuse. When you have beaten both a Dovo and a GD into shape, you have won your chops. At least as far as honing factory fresh razors goes.

Examine the toe closely under your bright work light with your loupe. Look for burrs or really big chips in the edge. Bits of fin or wire edge. And remember that the last tiny bit of the toe is really not that important. Don't grind away at it so much that you sweep the toe up into an exaggerated smile. The rest of the blade will eventually catch up to it.

-

05-03-2023, 04:53 PM #277

-

05-03-2023, 08:50 PM #278

Sounds like a plan. I'd be willing to buy that block and paper off of you as well, PM me the shipping estimate you get for that. Sometimes things can be totally reasonably to ship up to Grand Forks North Dakota, then cost way more the second you cross the border, so a lot of the time it's not really worth shipping from the USA to Canada. It depends, though.

This sheet you linked doesn't come in one micron and is made with a different abrasive. I think the original aluminum oxide green sheet I was looking at is the correct one, I'll call them to make sure. They do definitely know their stuff, I've been buying specialty drill bits and fasteners from them for over 10 years.

Looks like the "3M Aluminum Oxide Film" they sell is actually 268L "Microfinishing Film", in other words it is not lapping film. Which also means it is probably impossible to buy the 262x lapping film in Canada for a reasonable price. I wouldn't be surprised if this stuff works just as well for this purpose, as all the local sharpeners who use film at all probably use this exact film, but there certainly is not a lot of local straight razor honers.Last edited by rickytimothy; 05-03-2023 at 08:59 PM.

-

05-03-2023, 10:57 PM #279

If it is not lapping film, it is not lapping film. Will "microfinishing film" work? Probably, after a fashion. I don't do "probably" when I already know about "certainly". One of my cardinal rules is not to leave anything to chance. I highly recommend you use that approach so again, you know what or who to blame, and what to correct. I will send you some film, and the plates, no charge except for postage, and I suggest you use what I send you first. Then when you get a good edge or two, by all means, try the 268L. Who knows what will happen. It might just not be as durable, for instance. It might not cut as quickly. It might make deeper scratch pattern. I have no doubt that it will help to improve an 8k edge, but how much improvement, and at what cost, is the question. Lapping FILM is the sure thing and the sure thing has super obvious advantages when you are trying something new. Then again, you might find the stuff from Lee Valley to even be better than what I use. Maybe you hone 50 razors on one piece. So yeah, take one for the team, but let's get you as close to a sure fire thing going, as possible, for your first go at it.

Give me a couple of days and I will cut up a sheet and pack and weigh, and see what the postage is. PM me your full address. I have to give the app a real address to work with.

-

05-03-2023, 11:37 PM #280

Ok, I will send that shortly.

I wonder if there is a company neutral definition for what the difference is between "microfinishing film" and "lapping film". Seems like exactly the kind of thing that would have zero agreement between two competing companies about what the meaning is.

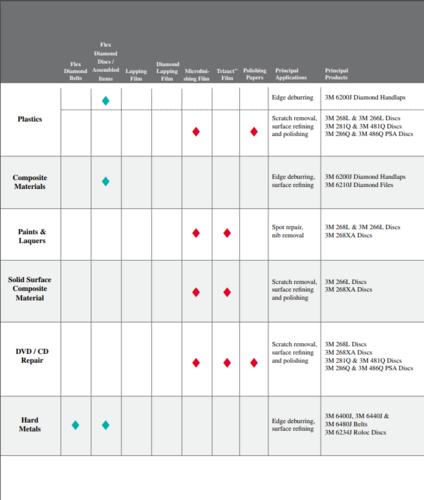

I found this PDF https://multimedia.3m.com/mws/media/...tion-guide.pdf that recommends applications: Here is a screenshot of the chart:

It doesn't seem to present any substantial information besides "red diamond in box."

edit: I didn't notice that below what chart there is another chart that is pretty specific, the only options they recommend for metallurgical lapping are 261x and the diamond lapping films, but they specify that diamond is more aggressive, so for something like this, I agree that 261x does look like the only practical option.Last edited by rickytimothy; 05-04-2023 at 02:53 AM.

333Likes

333Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote